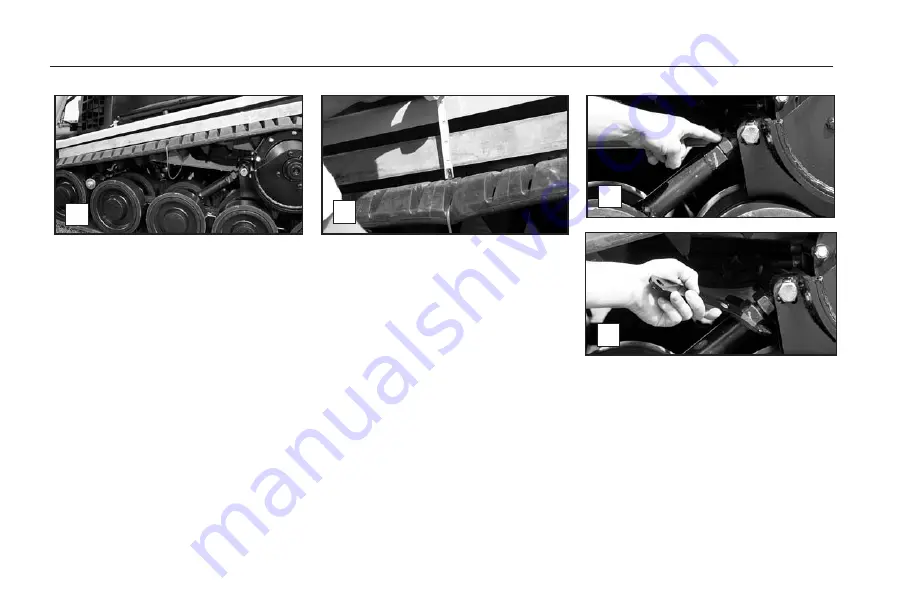

Track Tension

Proper track tension is very important for

optimum performance and maximum

track life. Operating with tracks that are

too loose can cause them to misfeed,

possibly causing damage. During the

first 50 hours of operation, the tracks will

"break-in", and may require adjustment.

To check for proper track adjustment:

1. Drive the machine forward 5 feet to

remove slack from the lower and rear

portions of the track.

2. Lay a straight edge along the top of

the track, across the sprocket and the

front idler wheel (photo A).

3. Using a rope or wire, put 50 lbs. of

down force on the track at the mid

point between the sprocket and idler.

4. Using a ruler or tape, measure the

distance between the straight edge

and track (photo B). The track should

not deflect more than .75" between

the top of the track and the straight

edge.

5. If the track does deflect more than

.75", tighten the track until within

specification.

To adjust the track tension:

1. Locate jam nut on track tensioner and

clean the threads thoroughly before

beginning procedure (photo C).

2. Using a wrench, loosen the jam nut

on the track tensioner.

3. After the jam nut is loosened turn the

tensioner until the track tension is

within specification (photo D).

4. Turn the tensioner the opposite direc-

tion to loosen the track.

5. Once proper tension is achieved,

retighten the jam nut on the tensioner.

If the track tensioner is stiff, it may be

helpful to slide a pipe over the end of

the wrench to increase leverage while

adjusting tension.

20

M

MA

AC

CH

HIIN

NE

E M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E

A

B

C

D