Rubber Track Loader

10. Transmission and Drive Disassembly and Assembly

10-3

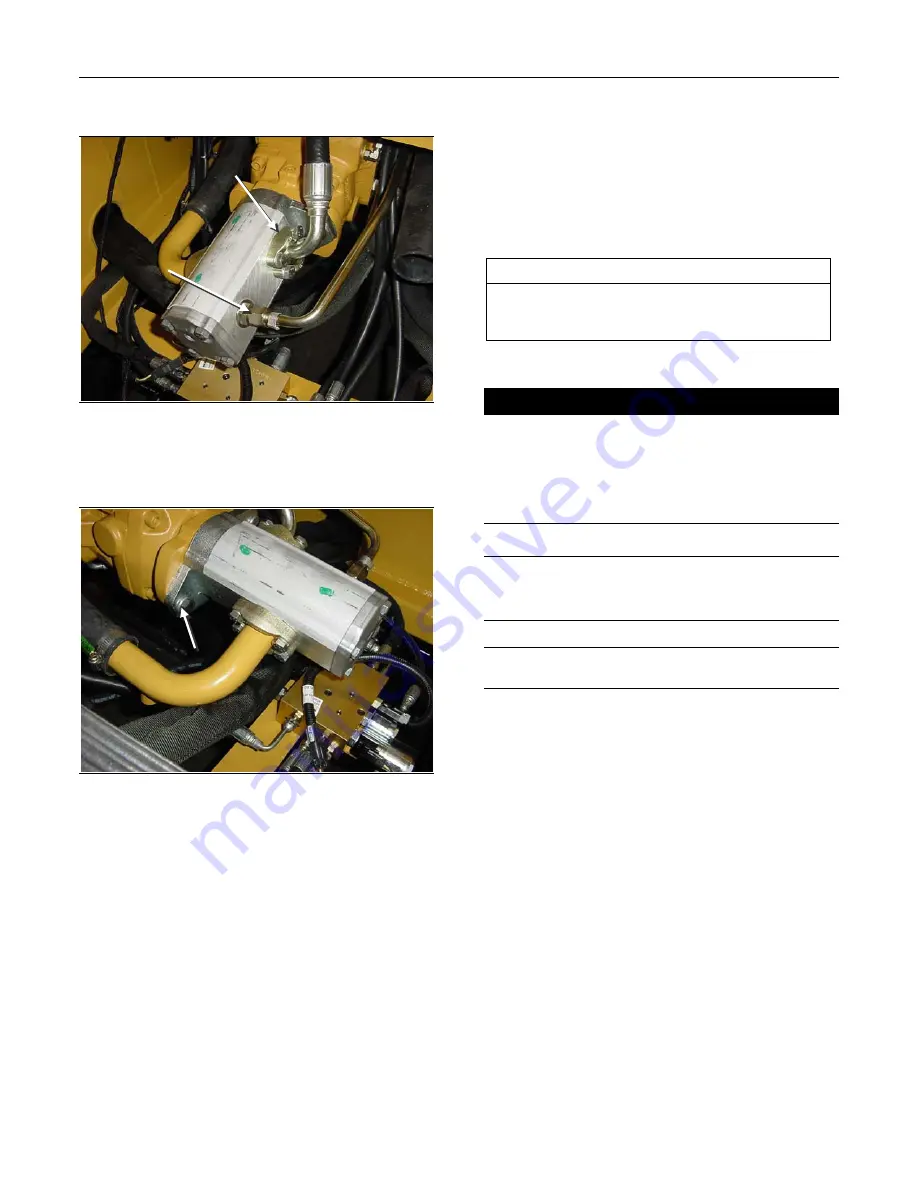

Figure 10-5

10-005

10.

Remove the other split flange fitting and the re-

maining tube and fitting.

Figure 10-6

10-006

11.

Remove the 2 bolts that mount the auxiliary gear

pump to the tandem pump, then remove it.

Tandem Pump Removal and

Installation

The tools required for tandem pump removal and

installation are listed in Table 10-2. Use manufac-

turer-recommended tools whenever possible.

Table 10-2

Required Tools

Screwdriver

Combination Wrench

Socket Wrench

Tandem Pump Removal

! WARNING !

Hot oil can cause personal injury. Lower all attach-

ments and make sure the oil is cool before removing

any components or lines.

Remove the oil filler cap only when the engine is

stopped and the machine has been allowed to cool

thoroughly.

NOTICE

Collect and contain liquids in a suitable container. Dispose

of all liquids according to local regulations and mandates.

Note

: During disassembly, cap all hoses and fittings to

prevent fluid loss and contamination of the system fluids.

1.

Lower the lift arms to the ground.

2.

Turn the ignition switch to the OFF position.

3.

Relieve hydraulic pressure from the auxiliary

circuit.

4.

Drain the hydraulic fluid. Refer to

Chapter 13.

Hydraulic Fluid and Filter Change

.

5.

Remove the seat. Refer to

Chapter 6. Seat Re-

moval

.

6.

Remove the auxiliary gear pump. Refer to

Chap-

ter 10.

Auxiliary Gear Pump Removal

.

7.

Remove the belly pan.

Remove

Tube and

Fitting

Remove

Split

Flange

Remove

Bolts