Grease Fittings

The undercarriages are

equipped with grease fittings at

the main torsion axle pivot

points. Lubricate fittings daily or

after every 10 hours of operation

to ensure proper operation and

maximize component life.

Track Tension

Proper track tension must be

maintained for optimal perform-

ance and track/undercarriage

life. Running a track that is too

loose may cause the track to

misfeed, possibly causing dam-

age to the track and or under-

carriage components. Running a

track that is too tight may cause

track stretch, premature bearing

failure, or other preventable

damage to the machine. Tracks

should only be tightened to the

point where there is no visible

sag (when viewed from the side)

between the rear sprocket and

the front idler wheels. Never

tighten the tracks beyond this

point.

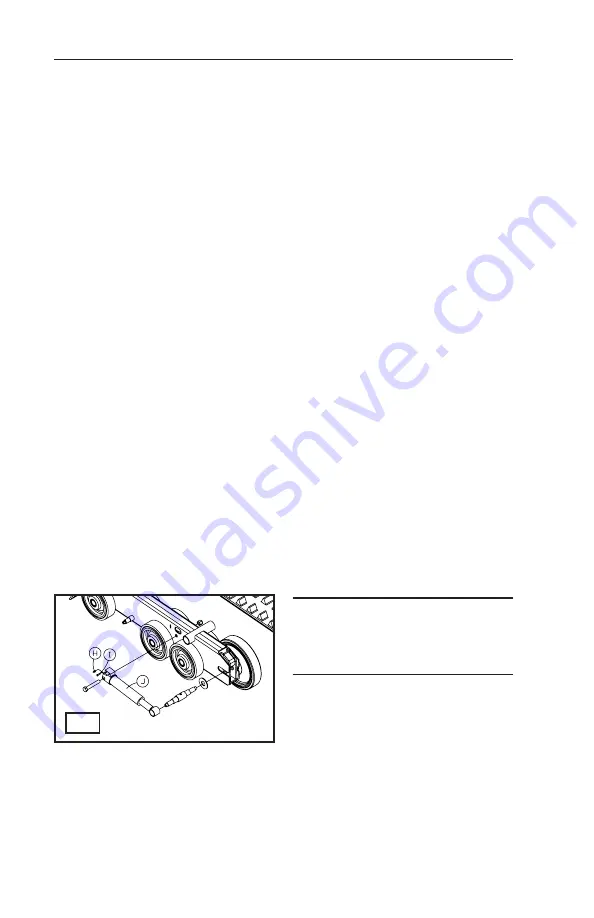

Adjustment

To tighten tracks:

1.

Locate the input grease zerk

(H) on the tensioner unit (J)

mounted within the frame rail.

(fig. 1)

2.

Connect a grease gun to the

zerk and inject grease

into the tensioner until the

track is properly tensioned.

The track tension adjustment

procedure is now complete.

If for some reason the tracks are

too tight, loosen them until ten-

sion is correct.

To loosen tracks:

1.

Locate the grease bleeder

bolt (I) adjacent to the input

zerk on the tensioner unit.

(fig. 1)

2.

Using a socket wrench and

extension, loosen the bleeder

bolt slowly until grease begins

to flow out from around the

bolt. Allow grease to bleed out

until track tension is correct.

Note:

During the first 50 hours

of operation the tracks will

"break-in" and will most likely

require adjustment.

MAINTENANCE

Undercarriages

39

1

Summary of Contents for ST50 Scout

Page 6: ...5 ...

Page 11: ...SAFETY Warning Decal Locations 10 A B B F D C C G E ...

Page 48: ...47 ...

Page 56: ...SERVICE LOG 55 Hours Service Performed Notes ...

Page 57: ...SERVICE LOG 56 Hours Service Performed Notes ...

Page 58: ...Hours Service Performed Notes SERVICE LOG 57 ...

Page 59: ...SERVICE LOG 58 Hours Service Performed Notes ...