Installation & Servicing Instructions ATAG E-Series

26

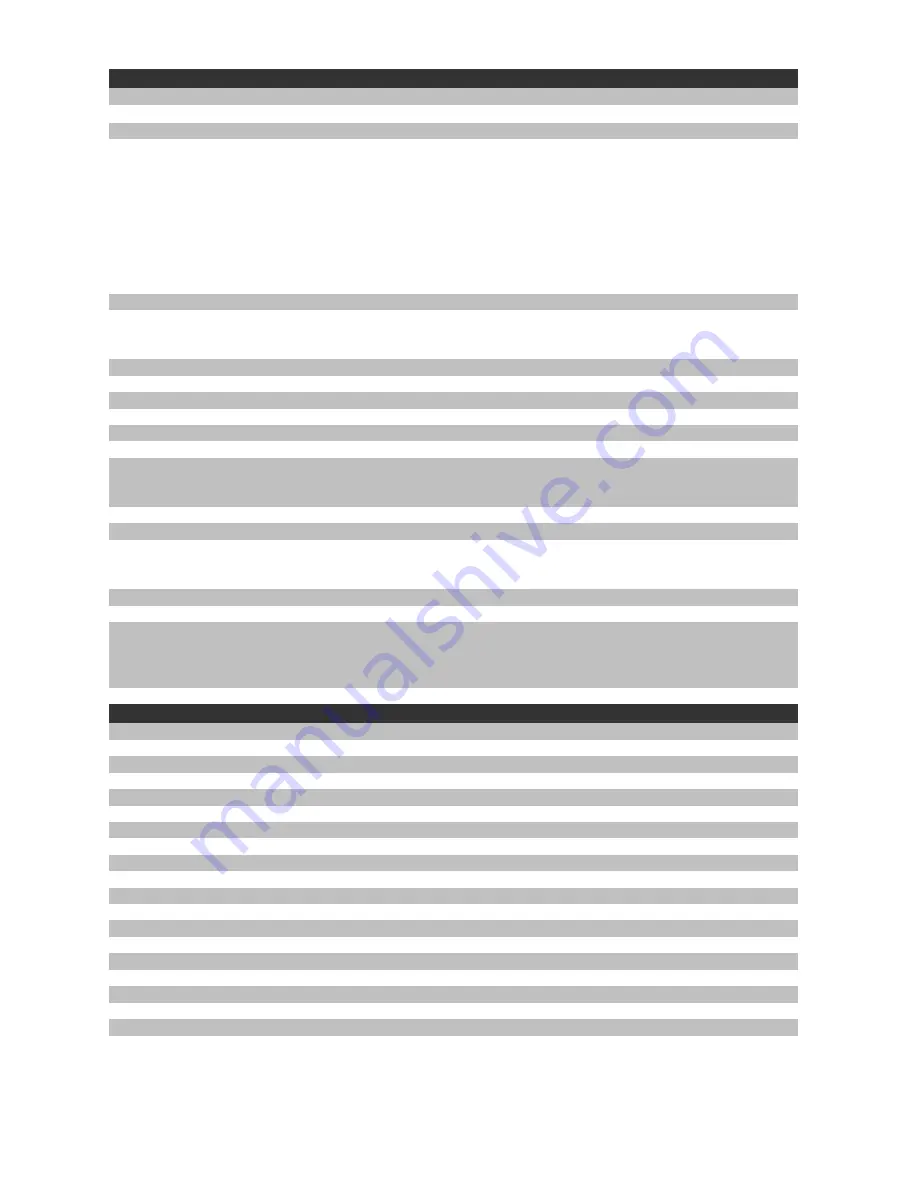

Parameter chapter

PARA

Factory

Description

Range

1

85°C

maximum flow temperature CH

20 - 90°C

2*

01

type of CH installation:

radiators; air heating; convectors:

T max. flow 85°C; K factor heating line 2.3; gradient 5°C/min; gear differential 6°C

01

radiators with large surface areas or underfloor heating as additional heating:

T max. flow 70°C; K factor heating line 1.8; gradient 5°C/min; gear differential 5°C

02

under floor heating with radiators as additional heating:

T max. flow 60°C; K factor heating line 1.5; gradient 4°C/min; gear differential 4°C

03

full under floor heating:

T max. flow 50°C; K factor heating line 1.0; gradient 3°C/min; gear differential 3°C

04

3

max.

maximum power CH in kW

min-max

4*

00

control principal with on / off thermostat:

100 % on / off thermostat

00

100 % on / off weather dependant

01

5*

2.3

heating line K-factor (see also heating line graph)

0.2 - 3.5

6*

1.4

heating line exponent (see also heating line graph)

1.1 - 1.4

7*

-10

heating line climate zone (see also heating line graph)

-20 - 0

10*

0°C

fine adjustment heating line day temperature

-5 until 5°C

11*

0°C

fine adjustment heating line night temperature

-5 until 5°C

14

7

gradient speed

0 - 15

15*

0

booster after night reduction:

no

00

yes

01

23

-3°C

frost safety temperature

-20 until 10°C

31

63°C

switch-off temperature of additional cylinder with E boiler

40 - 80°C

36

0

type of three-way valve

VC 2010 / VC 8010 / VC 8610

00

VC 6940 modulating

01

43

max.

maximum power DHW in kW

min-max

45

0

Not applicable

00 - 01

89

00

address setting interface:

Spare

-01

ATAG Bus thermostat (BrainQ, Smart)

00

boiler 1 - 8 in cascade

00 - 07

Information chapter

INFO

Value

Description

1

°C

flow water temperature T1

4

°C

return water temperature T2

5

°C

DHW temperature T3

7

°C

outside temperature T4

8

°C

flue gas temperature T5

16

%

actual power in %

17

kW

actual power in kW

18

kW

actual load in kW

20

indication bus communication

21

GJ

consumption total in GJ (.. x 33 = .. m3)

22

GJ

consumption CH in GJ (.. x 33 = .. m3)

23

GJ

consumption DHW in GJ (.. x 33 = .. m3)

24

hour

total number of burner run hours

25

hour

number of burner run hours CH

26

hour

number of burner run hours DHW

32

hour

total number of hours counter

37

hour

total number of run hours pump CH and DHW

46

hour

within how many hours is service required

Summary of Contents for E 22C

Page 39: ...20 KIWA Certificate...