Installation & Servicing Instructions ATAG E-Series

32

Ignition electrode

The replacement of the electrode is only necessary when the electrode is worn off. This

can be checked by measuring the ionisation current. The minimum ionisation current has

to be higher the 4µA on full load.

If the viewing glass is damaged the complete electrode must be replaced.

Replacement goes as follows:

-

remove the electrical connections of the electrode;

-

press the clips on both sides of the electrode to both sides and remove the complete

electrode;

-

remove and replace the gasket;

Refitting of the components is done in reverse order.

Siphon and condensate tray

-

first remove the condensate cup;

Check this for pollution. If there is no sign of strong pollution it is not necessary to clean

the condense tray. If there is a strong pollution in the cup it is necessary to remove

and clean the condensate tray;

-

check the O-rings of the cup as well as those from the pipe and replace if necessary;

-

clean both part by flushing it with clean water;

-

grease the O-rings again with acid free O-ring grease to make fitting easier;

-

if there is a leak at the siphon cup or tray the complete siphon unit has to be replaced

by S4421200;

-

remove the plug from the flue gas sensor if present;

-

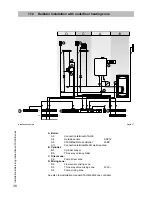

turn the two short clamping rods ¼ turn and remove them by pulling them forward; Note

the right turning direction (red indicator);

-

lift the flue gas pipe out of the condensate tray;

-

press the condensate tray carefully downwards and remove it by pulling it forward;

-

replace the gasket between condensate tray and heat exchanger by a new one;

-

clean the condensate tray with water and a hard brush;

-

check the condensate tray for leaks.

Refitting is done in reverse order.

Note thate the gasket of the condensate tray seals completely.

Make sure that during refitting of the clamping rods they are put in the right

position. They should be turned vertically.

Alway replace all removed gaskets of dismantled parts during the

maintenance activities.

Put the boiler into

operation and check

the CO

2

(see page 30).

Replace the secure

screws A, B, C, D

and E in the quick-

release fasteners

after the

maintenance

activities.

14.3

Warranty

For warranty conditions we refer to the warranty card supplied with the boiler.

vergrendeling mantel

figuur 13

Summary of Contents for E 22C

Page 39: ...20 KIWA Certificate...