Operation and maintenance manual AQUAmax

®

BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 6 from 40

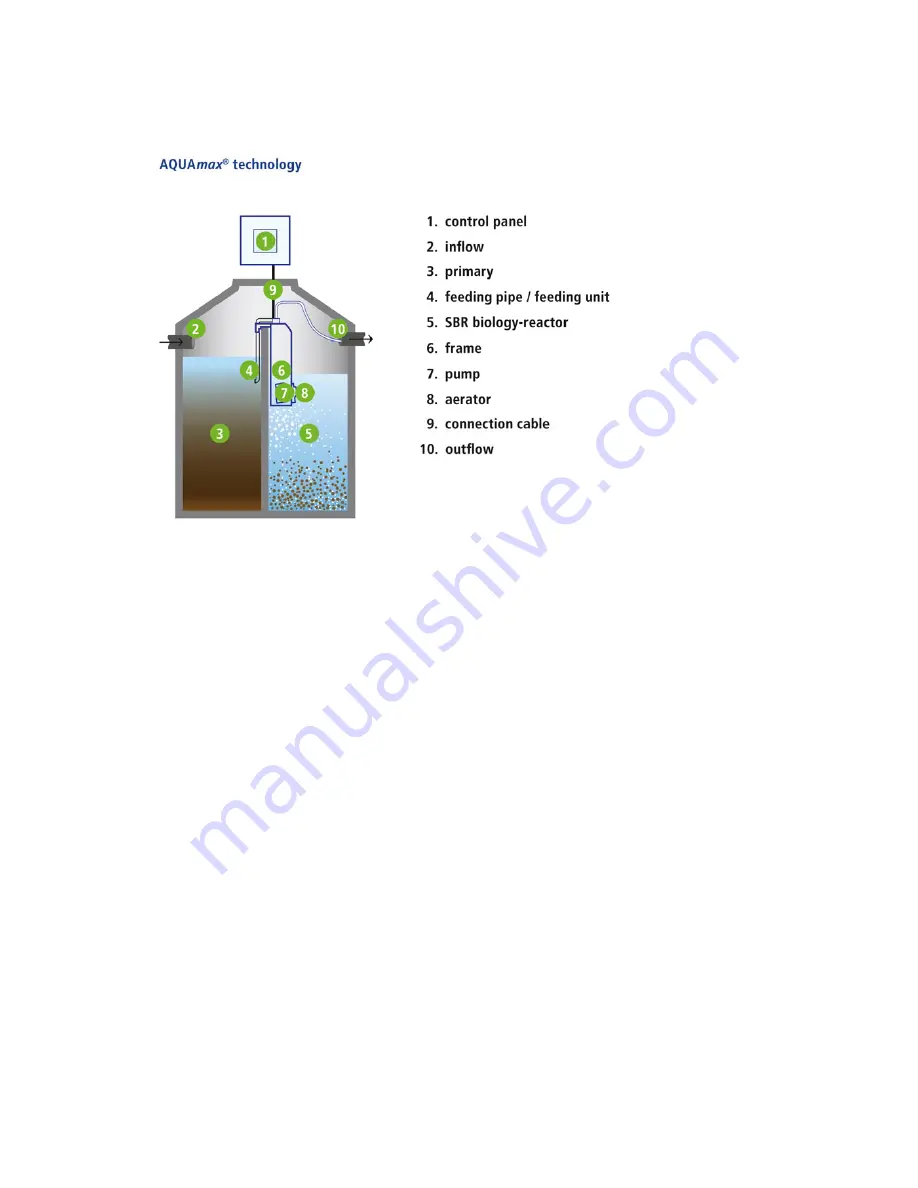

Functional Description

The wastewater treatment plant works according to the activated sludge principle using the

retention process (single tank or SBR plant). With this, the contaminants from the wastewater are

taken up by suspended micro-organisms (activated sludge) and converted into biomass.

The wastewater first reaches the coarse interceptor. Every 2 hours – according to the principle of a

communicating pipe and with the aid of an excess sludge pump – the retained wastewater is fed

into the aeration stage. The aeration takes place intermittently via a submersible motor aerator or

with a compressor and membrane tube diffusers on the tank bottom (CLASSIC ZB).

After 6 hours the aeration phase ends and the settling phase begins.

After 2 hours settling time the treated wastewater is pumped out using the clarified water pump.

The switch-off point is determined via a float switch. If, as a result of a pump defect, this minimum

water level is not achieved an alarm is triggered. After ca. 8 hours, with the end of the clarified

water removal, the cycle is ended and a new one begins.

The control unit can be matched to the respective requirement case. With commissioning the plant

is set to the maximum number of persons connected. A modification of this setting is not required

with short-term over or underloading.

The plant achieves its full treatment performance after a run-up period of ca. one month. With more

extreme underloading or temperatures under 12° C it can also take longer until the biology has

developed completely. In this case it is recommended to seed using activated sludge in order to

accelerate matters.

With the AQUA

max

®

BASIC charging, removal of excess sludge and the drawing off of clarified

water take place using only one pump. The water streams with this are fed into the individual areas

using a patented hydraulic system.

*alternatively membrane tube diffuser on the tank bottom

*