Applied Thermal Control Ltd

39 Hayhill Industrial Estate

Barrow-upon-Soar, Loughborough

LE12 8LD, United Kingdom

+44 (0) 1530 839 998

Service@thermalexchange.co.uk

Support@app-therm.com

Operating Manual; Controller Operation

Annex E-1

DOCUMENT DETAILS

Date 5/DEC/2019

Author(s) MJH

Page 2 / 9

Revision 1

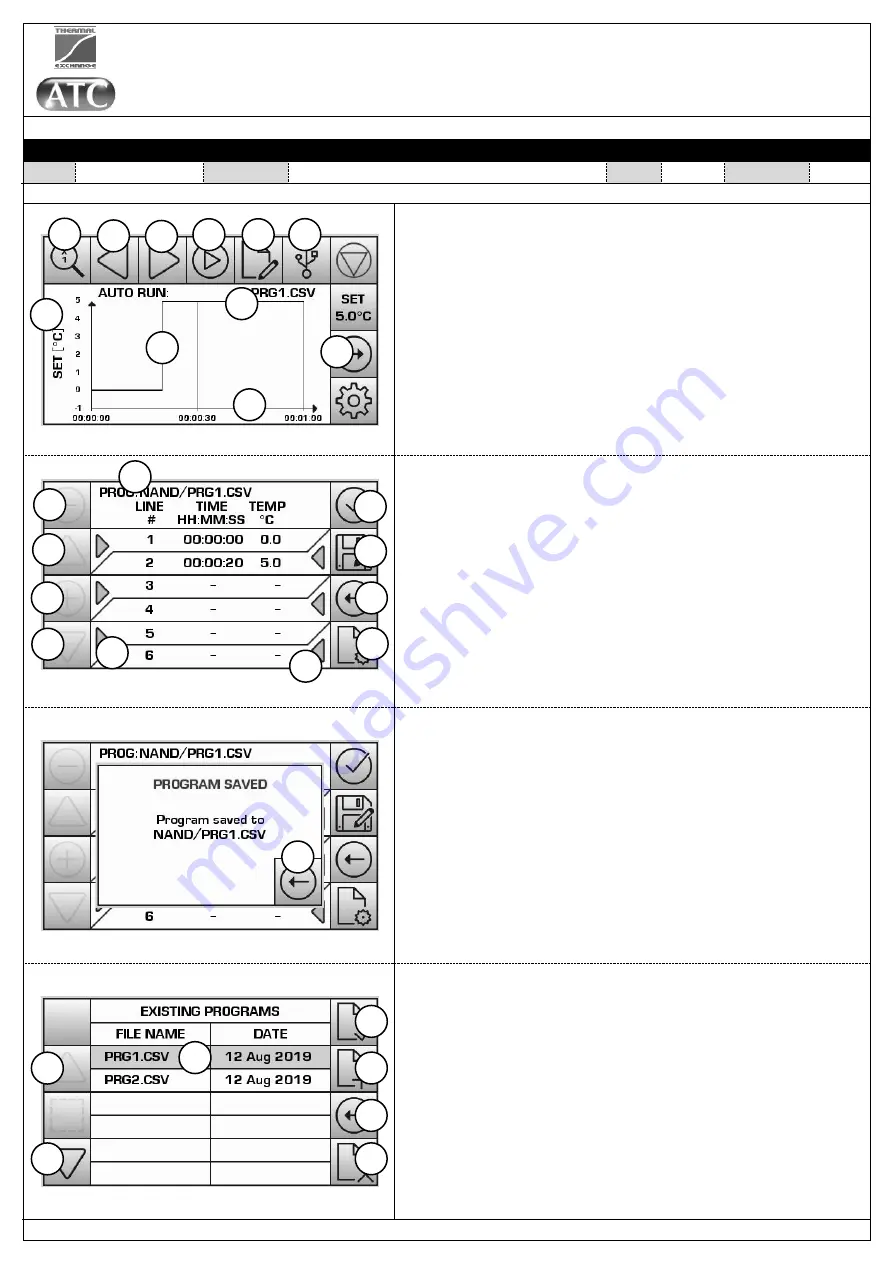

Program Mode

1. USB program loading and software management menu.

2. Create new or load existing program.

3. Start loaded program.

4. Scroll right through scheduled setpoints.

5. Scroll left through scheduled setpoints.

6. Adjusts the scale of the X axis to aid visibility of program.

7. Y axis shows the range of setpoint values in program.

8. Vertical line shows programmed change to setpoint temp.

9. Name of loaded program.

10. X axis shows time scale of entire program.

11. Move through carousel onto

‘Engineering View’

.

Manage Programs (generate, load from NAND and modify)

Menu accessible via

button ‘2’ under ‘Program Mode’.

1. Accept changes and revert to Program Mode above.

2. Save changes to local NAND memory.

3. Back button reverts to Program Mode above.

4. Takes you t

o ‘Existing Programs’ menu.

5. Name of loaded program in the course of being edited.

6. When line added, tapping the arrows first selects the line,

then allows editing of line time and setpoint temperature.

7. Delete the selected line.

8. Move up to earlier lines where program lines exceed 6.

9. Add a new line. Lines automatically move up if deleted.

10. Move down to later lines where program lines exceed 6.

Save screen

Appears when button ‘2’ from ‘Manage Programs’ is used.

1. Back out to

‘Manage Program’ menu.

Existing Programs in NAND Memory

M

enu accessible via button ‘4’ under ‘Manage Programs’.

1.

Load highlighted program (reverts to ‘Manage Programs’).

2. Copy highlighted program to new line.

3.

Return to ‘Manage Programs’.

4. Delete highlighted program (warning; no confirmation!)

5. Selected program is highlighted grey.

6.

When ≥2 programs are in the list, use up arrow to select.

7.

When ≥2 programs are in the list, use down arrow to select.

5

4

1

2

3

6

7

10

8

9

5

1

2

3

4

6

6

8

10

7

9

1

1

2

3

4

5

7

6

11

Annex E-1 200707 XTD controller XTD043RB-K620G&F (Mini at SW v39.4)

11