WARNING:

Always check for damaged, frayed or loose hoses and

Įƫ

ngs. Have any defec

Ɵ

ve or damaged parts

replaced immediately by qu

ĂůŝĮ

ed personnel.

WARNING:

Do not carry the tool by the hose. Protect the hose from sharp objects and heat.

WARNING:

Always use air hose and couplings with a minimum working pressure ra

Ɵ

ng of at least 1-1/2

Ɵ

mes

the maximum working pressure ra

Ɵ

ng of the tool.

WARNING:

Do not depress the tool trigger/lever when connec

Ɵ

ng the air supply hose.

WARNING:

Do not lock, tape, wire, or otherwise disable the “ON/OFF” valve in the “ON” posi

Ɵ

on. The trigger

must always be free to return to the “OFF” posi

Ɵ

on when released.

WARNING:

When the tool is not in use, shut o

ī

the air supply and press the trigger/lever to drain the air supply

line. If the tool is not to be used for a period of

Ɵ

me,

Į

rst lubricate, disconnect from the air supply and store in a clean

and dry loca

Ɵ

on at average room temperature.

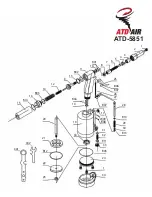

NOTE:

Typical Air Supply Installa

Ɵon

Always use clean, dry air. Dust, corrosive fumes and/or water in the airline will cause damage to the tool. Drain the air

tank daily. Clean the air inlet

Į

lter screen on at least a weekly schedule. The recommended hook up procedure can be

viewed in the above

Į

gure.

/ƚŝƐƌĞĐŽŵŵĞŶĚĞĚƚŽƵƐĞĂŶdͲϳϴϲϵ͕dͲϳϴϳϮŽƌƐŝŵŝůĂƌĮůƚĞƌ͕ƌĞŐƵůĂƚŽƌ

& lubricator with

this tool.

Lubricate the tool’s air motor daily with quality air tool oil. If no airline oiler is used, run 1/2 oz. of oil through the tool.

The oil can be squirted into the tool air inlet or into the hose at the nearest conne

ĐƟ

on to the air supply, then run into the

tool. Over

Į

lling will cause a redu

ĐƟ

on in the power of the tool.