23 24

Ω

Ω

Ω

Ω

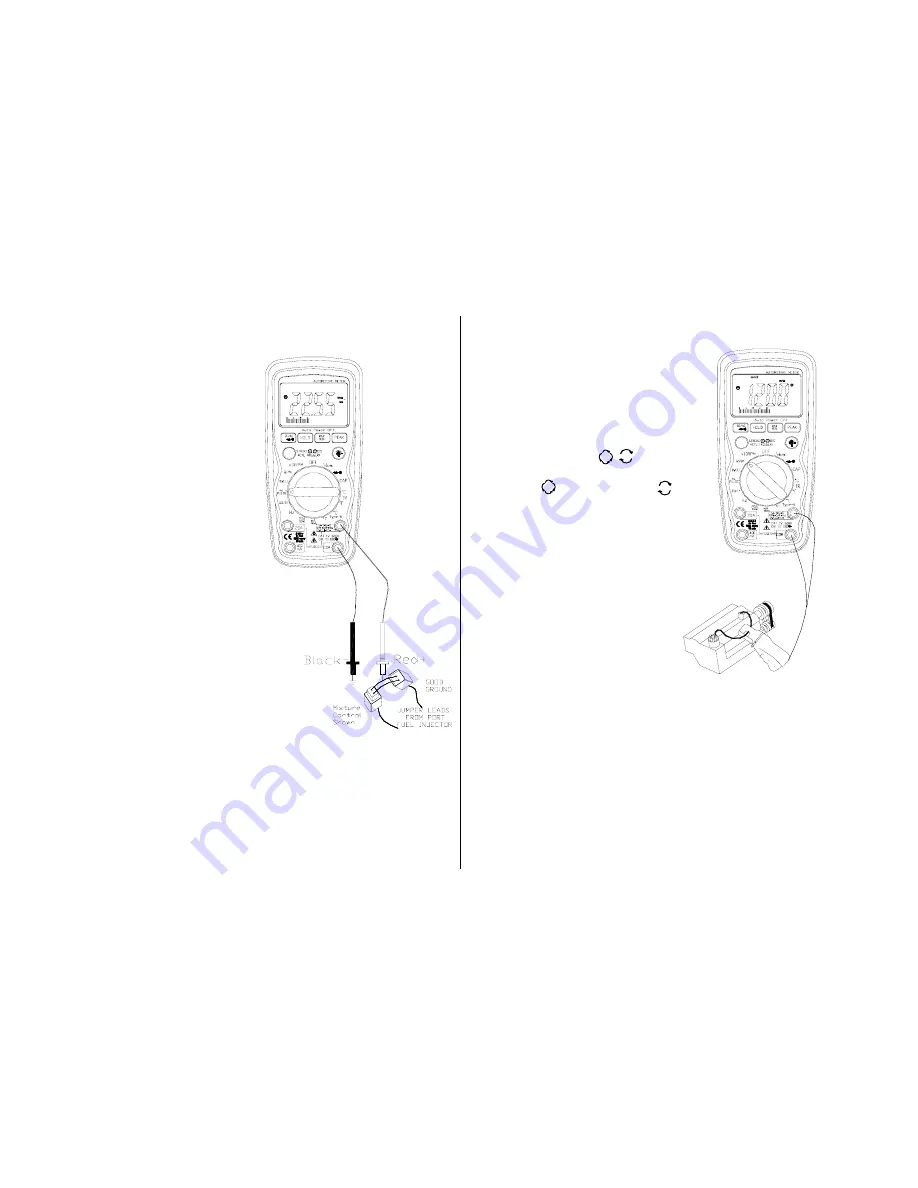

To measure pulse width (mS):

Select the

“mS-Pulse”

function with the rotary

switch .

Press the

±

TRIG button for

2 seconds until the negative

(-) trigger slope is displayed

on the upper left side of the

display.

NOTE : The applied time for

most fuel injectors is

displayed on the

negative (-) slope.

Insert:

Black lead in

COM

jack.

Red lead in

V-

Ω

-RPM

jack.

Connect:

Jumper wires between the fuel

injector and the harness

connector.

Black test probe to a good

ground at the fuel injector or the

negative (-) vehicle battery post.

Red test probe to the fuel

injector solenoid driver input on

the jumper cable.

Start the engine. A pulse width in

milliseconds should be read.

Note: Initially, the unit will read

“OL”, then readings will descend

and stabilize to the actual pulse

width. If “OL” remains,

re-check your connections.

Meter Functions-RPM/

×

10RPM

Select the

RPM

range with the

rotary switch.

OR

Select the

×

10RPM

range

with the rotary switch (1,000 to

12,000 RPM). Multiply the

displayed reading by ten to get

actual RPM.

Press STROKE / DIS

button to select through

RPM for 4-stroke, RPM

for 2-stroke and DIS ignitions.

Insert the inductive pickup

connecting terminals into the

meter.

Black lead in

COM

terminal.

Red lead in

V-

Ω

-RPM

terminal.

Connect the inductive pickup to

a spark plug wire. If no reading

is received, unhook the clamp,

turn it over and connect again.

Note:

Position the inductive pick-up as far away from the distributor and the

exhaust manifold as possible.

Position the inductive pick-up to within six inches of the spark plug or move

it to another plug wire if no reading or an erratic reading is received.

RPM 4

:

For RPM of 4-stroke engines which have 1 ignition on

every 4 engine strokes

RPM 2 :

For RPM of DIS ( Distributorless lgnition System) &

2-stroke engines which Have 1 ignition on every 2

engine strokes

PLEASE NOTE- THE RPM PICK-UP HAS AN ADJUSTABLE SENSITIVITY

SWITCH THAT CAN ALSO BE USED TO CORRECT AN

UNSTABLE READING.

4

2

4

2