: Repairs should be carried out by a qualified person.

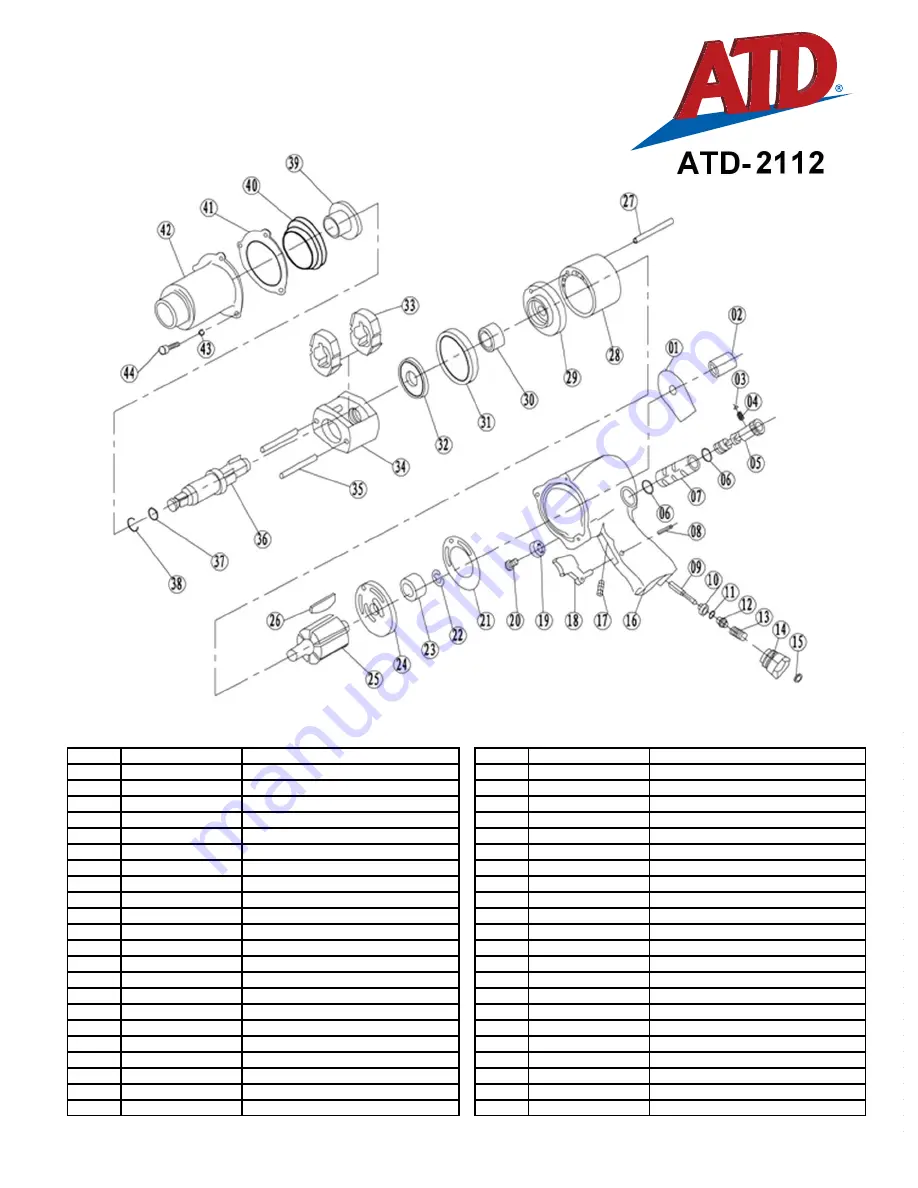

ITEM# ORDERING PART# PART DESCRIPTION

ITEM# ORDERING PART# PART DESCRIPTION

1

PRT2112-01

WARNING LABEL

23

PRT2112-23

BEARING

2

PRT2112-02

OIL INLET CUP

24

PRT2112-24

END PLATE

3

PRT2112-03

STEEL BALL

25

PRT2112-25

ROTOR

4

PRT2112-04

ADJ. SPRING

26

PRT2112-26

ROTOR BLADE

5

PRT2112-05

REGULATING SCREW

27

PRT2112-27

PIN

6

PRT2112-06

O-RING 10.6×1.8

28

PRT2112-28

CYLINDER

7

PRT2112-07

VALVE SLEEVE

29

PRT2112-29

FRONT PLATE

8

PRT2112-08

PIN

30

PRT2112-30

BEARING

9

PRT2112-09

VALVE STEM

31

PRT2112-31

GASKET

10

PRT2112-10

THROTTLE VALVE BUSHING

32

PRT2112-32

WASHER

11

PRT2112-11

O-RING 7.6×1.8

33

PRT2112-33

HAMMER DOG

12

PRT2112-12

VALVE STEM SCREW

34

PRT2112-34

HAMMER CAGE

13

PRT2112-13

INLET SPRING

35

PRT2112-35

HAMMER PIN

14

PRT2112-14

AIR INLET PLUG

36

PRT2112-36

ANVIL

15

PRT2112-15

DUST GUARD COVER

37

PRT2112-37

O-RING7.65×1.78

16

PRT2112-16

HOUSING

38

PRT2112-38

ANVIL COLLAR

17

PRT2112-17

BOLT M8×8

39

PRT2112-39

ANVIL BUSHING

18

PRT2112-18

TRIGGER

40

PRT2112-40

FIXING RING

19

PRT2112-19

ADJ. SCREW CAP

41

PRT2112-41

GASKET

20

PRT2112-20

BOLT M6×10

42

PRT2112-42

HAMMER CASE

21

PRT2112-21

SEAL WASHER

43

PRT2112-43

WASHER

22

PRT2112-22

RETAINER RING

44

PRT2112-44

BOLT