BATTERY REPLACEMENT

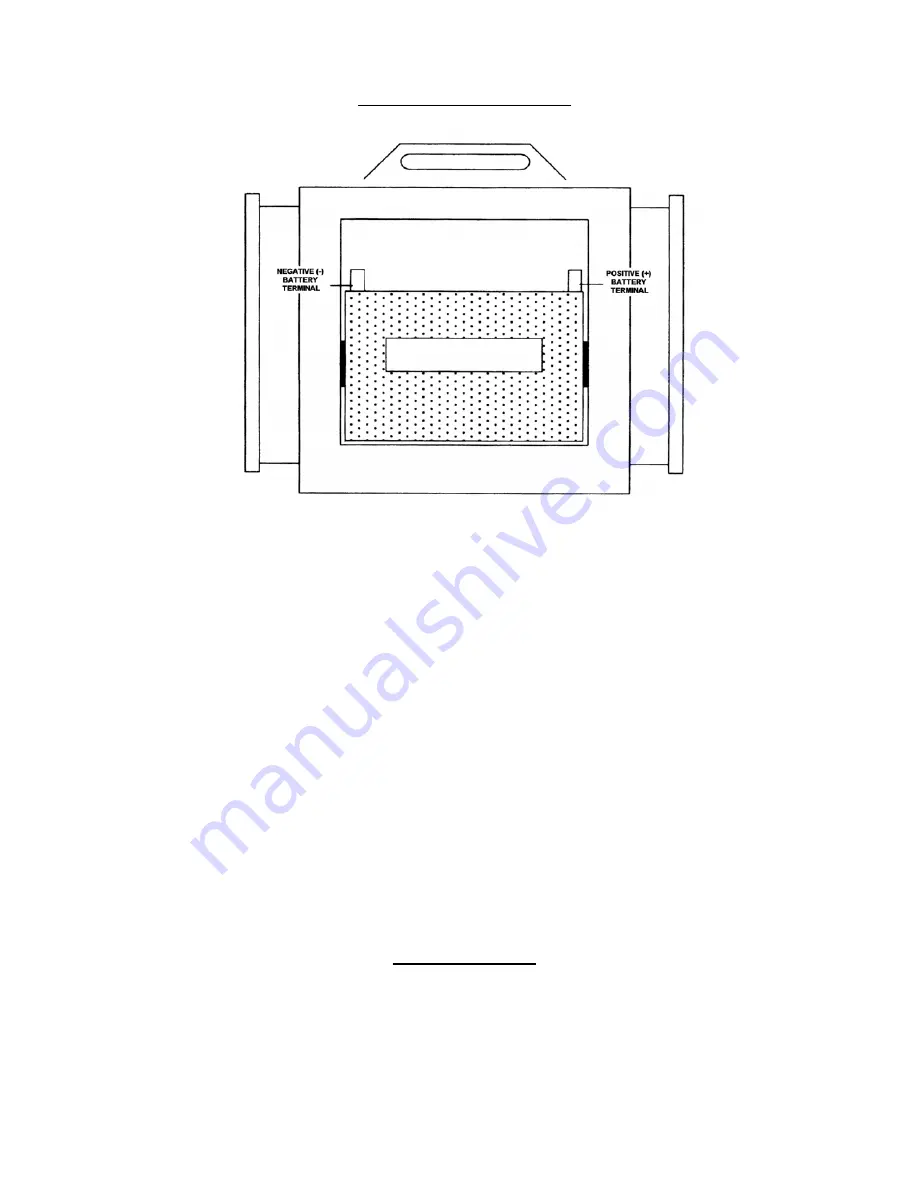

FIGURE 3

. - REAR VIEW OF THE POWER PACK UNIT SHOWING THE BATTERY COMPARTMENT

1.

UNSCREW AND REMOVE THE EIGHT (10) PHILLIPS HEAD SCREWS THAT HOLD THE REAR COVER IN PLACE ON THE BACK OF YOUR POWER

PACK UNIT.

2.

LIFT OFF THE COVER PLATE TO EXPOSE THE BATTERY COMPARTMENT.

3.

LIFT THE BATTERY OUT OF THE BATTERY COMPARTMENT.

4.

DETACH THE #4 JUMPER CABLES AND THE RED AND BLACK RECHARGING WIRES FROM THE BATTERY TERMINALS .

5.

ENSURE THAT THE REPLACEMENT BATTERY IS ORIENTED WITH THE POSITIVE ON THE RIGHT SIDE AND THE NEGATIVE ON THE LEFT

SIDE, JUST AS THE OLD BATTERY CAME OUT.

6.

CONNECT THE RED #4 JUMPER CABLE AND RED RECHARGING WIRE TO THE POSITIVE (+) BATTERY TERMINAL (ALSO MARKED WITH RED),

THEN CONNECT THE BLACK #4 JUMPER CABLE AND RECHARGING WIRE TO THE NEGATIVE (-) BATTERY TERMINAL. DOUBLE CHECK ALL

CONNECTIONS, AND TIGHTEN.

7.

TAKING CARE NOT TO DAMAGE THE CIRCUIT BOARD, SLIDE THE NEW BATTERY IN POSITION.

8.

REPLACE THE BATTERY COMPARTMENT COVER AND SECURE IN PLACE WITH THE EIGHT (10) PHILLIPS HEAD) SCREWS.

EMERGENCY LIGHT-BULB REPLACEMENT

1. GENTLY SQUEEZE THE SIDES OF THE EMERGENCY LIGHT LENS BEZEL TOGETHER AND REMOVE THE LENS AND BEZEL.

2. UNSCREW AND REMOVE THE BURNED OUT BULB.

3. REPLACE WITH A NEW BULB.

4. SNAP THE LENS AND BEZEL IN PLACE.

SPECIFICATIONS

ITEM #

. . . . . . . …. . . . . . . . . . . . . . . . . . . .ATD-5925

VOLTAGE

. . . . . . . . . . . . . . . . . . . . . . . . . .12V DC

BOOST POWER

. . . . . . . . . . . . . . . . . . . . .400 CRANKING AMPS

PEAK AMPS

… …...…….. . . .. . . . . . . . . . .900 AMPS

BATTERY TYPE

. . . . . . . . . . . . . . . . . . . . .SEALED, LEAD- ACID, RECHARGEABLE, MAINTENANCE-FREE, 12V DC, 18-AMP-HOURS

BOOSTER CABLES

. . . . . . . . . . . . . . . . . .43”, #4 AWG 100% COPPER CABLES WITH 500 AMP "ALLIGATOR" CLAMPS

DIMENSIONS

…. . . . . . . . . . . . . . . . . . . . .30 x 27 x 9 CM

AIR COMPRESSOR

………………………..260 PSI

Summary of Contents for ATD-5925

Page 7: ......