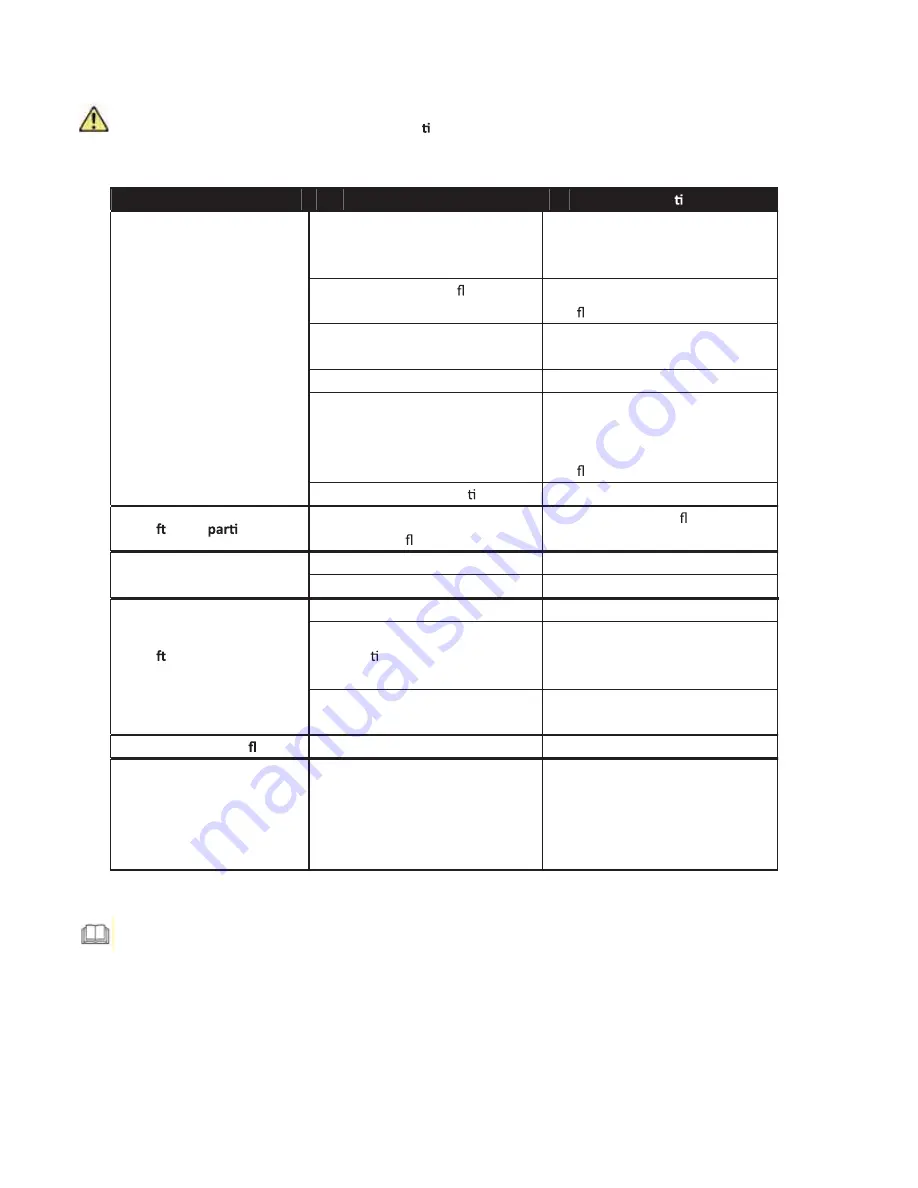

TROUBLESHOOTING:

CAUTION:

To prevent personal injury, all inspec on, maintenance, and repair procedures must be performed when

the jack is free of load.

Trouble

Cause

Solu on

Jack does not l

ŝŌ

1. Release valve is open

1. Verify the release valve is

closed. Release valve may

need cleaning

2. Low/no

hydraulic uid in

reservoir

2. Fill with approved hydraulic

uid and bleed system

3. Air

trapped

in

hydraulic

system

3. Follow the purge air

procedure

4. Load is above capacity of jack

4. Use the correct equipment

5. Delivery valve and/or bypass

valve not working correctly

5. Clean to remove dirt or

foreign objects from the

system. Replace hydraulic

uid

6. Seals worn or defec ve 6. Replace

seals

Jack li s only

ally

1. Too much or not enough

hydraulic uid

1. Check hydraulic uid level

Jack advances slowly

1. Pump not working correctly

1. Rework pump

2. Seals leaking

2. Replace seals/O-rings

Jack li s load, but doesn't

hold

1. Cylinder packing is leaking

1. Replace packing

2. Valve

not

working

correctly.

(Suc on, delivery, release or

bypass)

2. Inspect valves. Replace if

necessary

3. Air

trapped

in

hydraulic

system

3. Follow the purge air

procedure

Jack leaks hydraulic uid

1. Worn or damaged seals

1. Replace seals

Jack will not retract

1. Release valve is closed

1. Open the release valve by

turning the handle

counterclockwise (CCW).

Maybe necessary to clean

release valve

NOTE:

Should you need assistance with parts, service or warranty, please contact your distributor

or point of sale.