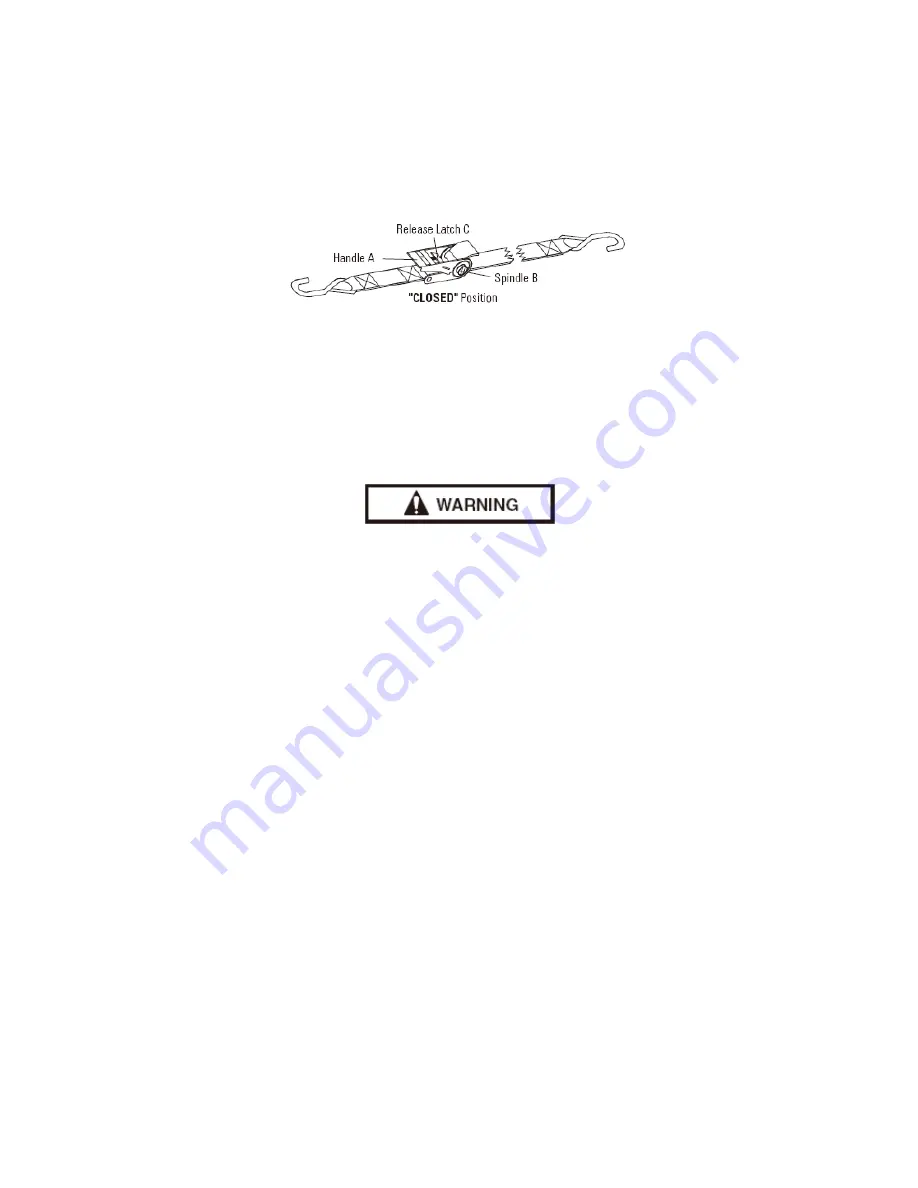

4. To lock ratchet, ALWAYS leave the handle in the closed position.

RELEASING THE LOAD-1-in. x 15-ft. Ratchet Tie Down Straps

Working limited:

250Lbs

Max load capacity:

800Lbs

1. Hold the ratchet in one hand and with the other hand pull back on Release Latch (C) that is located on

Handle (A).

2. While holding Release Latch (C) back, open Handle (A) fully past the locking gears until Latch (C) locks in a

completely open position or until the load releases.

CAUTION:

The load will release at this point.

3. To loosen or remove strap, pull up on ratchet and slide strap out of Spindle (B).

FOR

TIE

DOWN

STRAP

1.

DO

NOT

use

tie

down

strap

for

towing

vehicles

or

to

hold

or

suspend

human

weight.

2.

DO

NOT

use

extension

bar

lever,

pliers

or

any

tools

to

operate

as

a

handle.

Use

hand

power

only.

3.

Protect

strap

webbing

from

sharp

edges,

heat

and

acid.

Replace

strap

webbing

if

it

is

cut,

worn

or

damaged.

Inspect

strap

webbing,

hooks

and

hardware

before

each

use.

MAINTENANCE

IMPORTANT:

Before

performing

any

maintenance

of

the

bottle

jack

ALWAYS

detach

from

the

frame

and

place

on

a

level

surface.

AIR

PURGING

INSTRUCTIONS

With

the

ram

fully

retracted,

locate

and

remove

the

oil

filler

plug.

Insert

the

foot

pedal

into

the

sleeve

of

Hydraulic

Ram,

and

then

pump

6

to

8

strokes.

This

will

help

release

any

pressurized

air

which

may

be

trapped

in

the

reservoir.

Be

sure

that

the

oil

level

is

just

below

the

oil

filler

plug

hole.

Reinstall

the

oil

filler

plug.

Sometimes

during

shipment

and

handling,

air

may

become

trapped

in

the

hydraulic

system

causing

poor

or

no

lifting.

OIL

LEVEL:

IMPORTANT:

When

adding

or

replacing

oil,

always

use

a

good

grade

of

hydraulic

jack

oil,

transmission

oil

or

turbine

oil

and

always

avoid

mixing

different

types

of

oil.

Never

use

brake

fluid,

alcohol,

glycerine,

detergent

motor

oil

or

dirty

oil

of

any

kind.

Improper

oil

usage

will

cause

serious

internal

damage

to

jack.

ADDING

OIL:

With

ram

fully

lowered

and

jack

on

level

ground,

remove

oil

fill

plug.

Add

oil

if

level

is

more

than

1/4"

below

hole

replace

cover

plate.

REPLACING

OIL:

For

best

performance

and

longest

life,

oil

should

be

replaced

at

least

once

every

year.

To

drain

oil,

remove

cover

plate,

oil

filler

plug

and

release

valve.

Be

VERY

CAREFUL

to

not

allow

dirt

or

any

foreign

matter

into

the

system.

LUBRICATION:

Put

grease

in

fitting

on

base

and

lubricate

lifting

arm

spindle

with

oil,

every

3

months.

Summary of Contents for ATD-7461

Page 7: ......