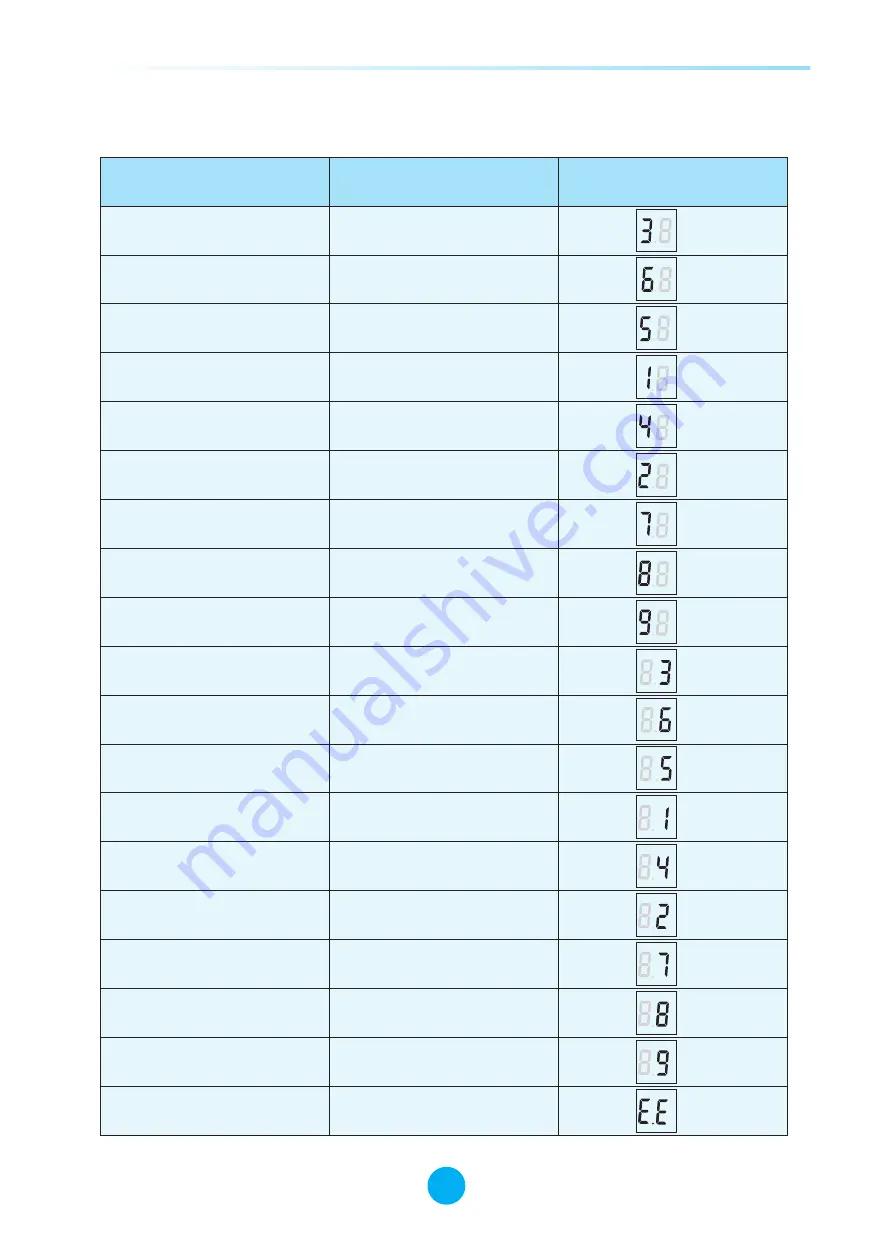

Protect/Failure

Wire Controller

Protect-300 LED Code

System 1

Low pressure protection

System 1

High pressure protection

System 1

Over current protection

System 1

Refrigerant anti-freeze

protection

System 1

Exhaust gas over-high

temp. protection

System 1

Refrigerant leakage

protection

System 1

Exhaust gas temp.

sensor failure

System 2

Low pressure protection

System 2

High pressure protection

System 2

Over current protection

System 2

Refrigerant anti-freeze

protection

System 2

Exhaust gas over-high

temp. protection

System 2

Refrigerant leakage

protection

System 2

Exhaust gas temp.

sensor failure

Wrong phase

or lack of phase

System 1

Refrigerant in temp.

sensor failure

System 1

Refrigerant out temp.

sensor failure

System 2

Refrigerant in temp.

sensor failure

System 2

Refrigerant out temp.

sensor failure

EE01

EE04

EE01

EE01

EE01

EE01

EE01

EE01

EE01

EE01

EE02

EE02

EE02

EE02

EE02

EE02

EE02

EE02

EE02

SWIMMING POOL HEAT PUMP

SWIMMING POOL HEAT PUMP

7.5 Overview of protect-300 failure code (3 phase unit)

27