17

56

01 0275 07

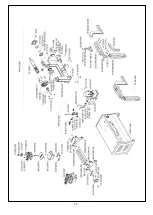

Engine

57

86R 03 000-CE

Lathe Unit Group

58

86R 03 001-CE

Right Connection Group Of Lathe Unit

59

86R 03 002-CE

Left Connection Group Of Lathe Unit

60

86R 03 003-CE

Sport Skidding Metal Sheet

61

86R 03 004-CE

Sport Handling Axle

62

84 03 005

Bearing Stopping Plate

63

84 03 006

Supporting Plate For Arm Connection

64

01 0073 025

Imbus Bolt Screw

65

84 03 007D

Fixing Screw Group

66

01 0064 025

Bolt

67

01 0315 005

Swivel Arm

68

01 0139 017

Segment

69

01 0053 06203-FAG

Bearing

70

01 0315 004

Wheel

71

84 03 007A

Body Group

72

84 03 007B

Sport Turning Plate

73

84 03 007C

Slider Locking Plate

74

84 03 007E

Square Nut

75

01 0074 070

Imbus Bolt Screw

76

01 0074 035

Imbus Bolt Screw

77

01 0050 01

Fixed Sport

78

01 0047 02

Tool Bit ( Lathe Cutter )

79

01 0083 90

Bolt

80

15 37 001

Grooving Holder Connecting Equipment

81

01 0114 05

Lathe Unit To Stop Switchcrank

82

86R 05 000-CE

Hydraulic Unıt Group

83

01 0159 27

Power Unit

84

01 0014 176

Record Body

85

01 0131 1-4

Copper Flake 1/4

86

01 0014 79

Record Thimple

87

01 0014 23C

Pipe Squeezing Nut

88

01 0131 3-8

Copper Flake

89

01 0014 20

Record Body

90

84 07 001

Hydraulic Unıt Connection Sheet Metal

91

01 0112 06

Washer

92

01 0061 020

Bolt

93

01 0117 006

Fiber Nut

94

01 0112 08

Washer

95

01 0115 008

Nut

96

15 30 001

Valve Lever Shaft

97

01 0014 21

Record

98

01 0157 01

Hydraulic Valve

99

86R 05 001-CE

Pressure Pipe

100

86R 05 002-CE

Discharge Pipe

101

01 0016 1800

Hydraulic Hoses

102

86R 04 000-CE

Cabin Group

103

86R 04 001-CE

Cabin Right Body Group

104

86R 04 002-CE

Cabin Left Body Group

105

84 05 003

Cabin Top Body Group

106

86R 04 003-CE

Cabin Inner Cover Plate

107

86R 04 004-CE

Cabin External Cover Plate

108

01 0039 121

Top Cover.

109

01 0030 49

İgnition

110

01 0030 73

İgnition

111

01 0030 20

Hydraulic Unit Start-Stop Switch

112

01 0030 95

Button

113

01 0030 97

Button