9

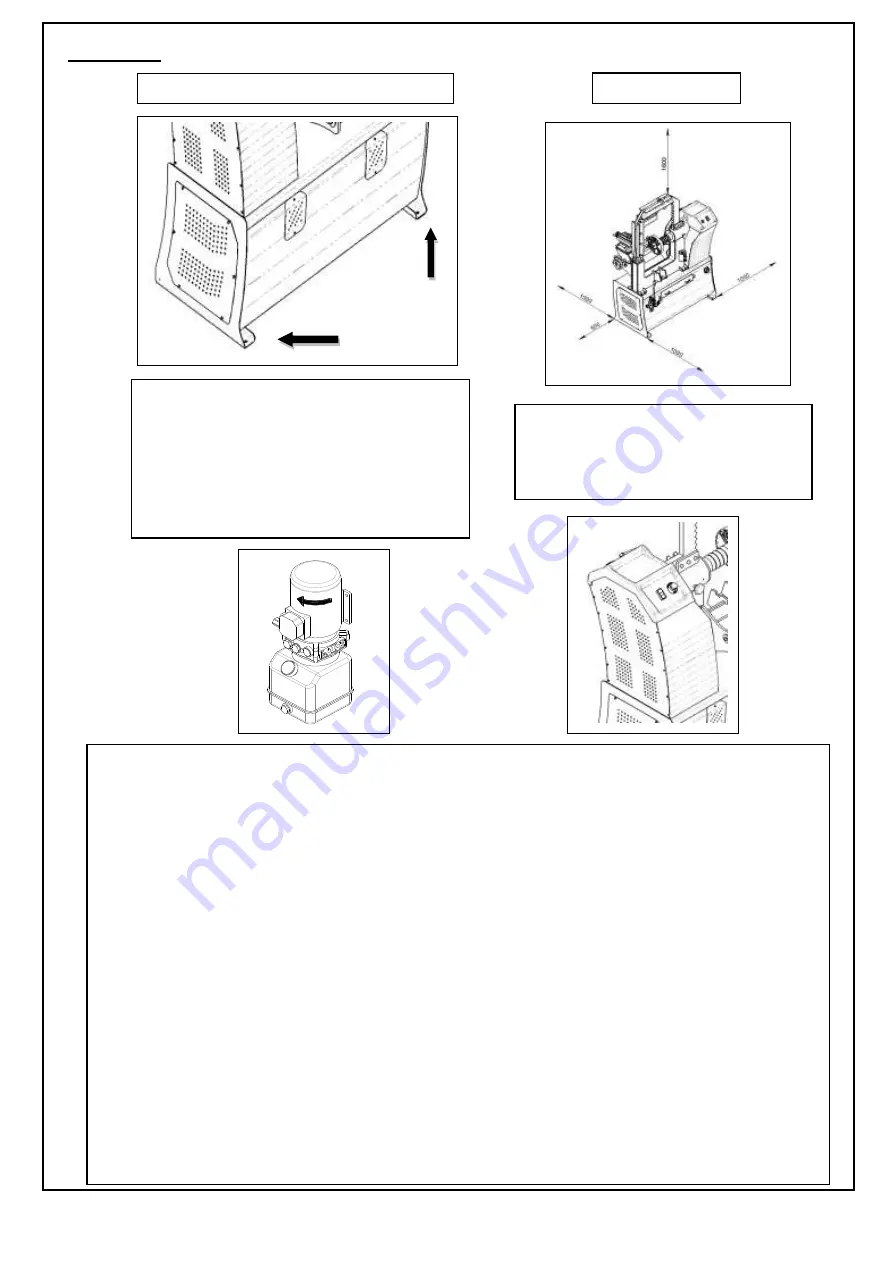

MACHINE FIXING ONTO FLOOR

LOCATION

For a good functioning the machine must be fixed

onto floor with expansion dowels.

1.

1)Drill the floor with a helical concrete bit with a diameter of

15 mm. , using the holes in the base as a drilling template.

2)Move the rim repair and insert anchor bolts into the

drills,then set the machine in the place to be fixed.

3)Insert into the anchor bolts and use a torque wrench

(setting of 25 N / m) to tighten..

SAFE DISTANCE:

For the safe and ergonomic use of the

machine it is advisable to locate it so as to

allow work, in conditions of complete safety.

ALL WORK ON THE ELECTRICAL SYSTEM, INCLUDING MINOR OPERATIONS , MUST BE CARRIED

OUT BY PROFESSIONALLY QUALIFIED PERSONNEL

Check that the mains supply is the same as that shown on the registration plate.

Connect the cable to a plug that conforms with European norms or to the norms of the country in which the

machine used.

The plug must have an earth terminal.

Check that the earth connection is effective.

The machine must be connected to the mains through a multipole isolating switch which conforms with

European norms and with contact openings of at least 3 mm.

Check that the multipole connector on the electrical board is correctly connected.

When the machine is connected switch it on and check the correct direction of rotation;this should be as shown

by the arrow on the motor unit.

If the rotation is reversed,reserve the two wires in the connection plug.

If the machine behaves abnormally,immediately press the emergency button and switch off the main switch

and check the section “Malfunctions:causes and possible remedies” in the instructions Manual.

THE MANUFACTURER DOES NOT ACCEPT ANY RESPONSIBILITY FOR THE FAILURE TO OBSERVE THE

ABOVE MENTIONED INSTRUCTIONS.

CLAUSE 9