1.-GENERAL SAFETY

2.- TRANSPORT AND HANDLING

.

If not otherwise specified, it is recommended that requirements of the latest national or international

electrical standards be used.

isable to cover the

modules with an opaque material. Do not touch the terminals with both hands and always use

insulated tools on the electrical connections.

Only allow access to the facility by qualified personnel.

Reversing the polarity of the cables destroys the bypass diodes of the junction box.

In normal conditions, the module can produce more current or voltage than the indicated for standard

measurement conditions. So that, when dimensioning the system (cables section, fuses,…) the Isc

and Voc values should be multiplied by 1,25.

Keep children and animals away from PV modules.

Install the modules in a strong structure and that this maintains the fire safety class.

Avoid uneven shade on the PV module surface. Shaded cells may become hot (“hot spot”

phenomenon) which may result in permanent damage to the module.

Follow all safety precautions of other system components used.

Use module for its intended function only.

Store modules in a dry and ventilated room.

Do NOT place modules on an uneven surface

Do NOT place excessive loads on the module or twist the module frame, it may cause severe micro-

cracks at the cell level

Do NOT stand, step, walk and/or jump on the module.

Do NOT drop module or allow objects to fall on module.

Do NOT mark the modules with sharp instrument. Avoid the contact of module back sheet with sharp

objects, as scratches may directly affect product safety

Do not use the junction box to hold or transport the module.

Broken or damaged modules must be handled carefully and with appropriate protective

equipment.(Broken glass can be sharp and can cause injury if it is not handled int he right way .

When carrying a bigger module, two or more people should carry it by its frame and wear non-slip

gloves (to avoid injury by a slipping module, cuts by the edge of a frame etc.

Module placement unsafely before installation can cause breakage, excessive deformation ... that

affect the reliability of the module.

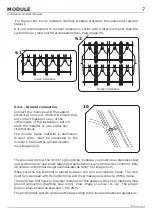

Modules must NOT be manipulated from the central part of the long sides of the frame.´

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

The modules must be handled carefully during transport, storage and unpacking.

The safety instructions contained in this manual must be strictly followed in order to

guarantee the safety of the user and the integrity of the module.

x

x

Ensure that the installation instructions provided in this document are followed. Guarantees or claims

will not be valid if the described process has not been followed

The cable pathway must provide mechanical support for the conductors and must provide sufficient

protection, in accordance with the Low Voltage Electrotechnical Regulations (REBT).

It must be handled by qualified personnel only. When exposed to the light, the modules generate

electricity. If several modules are connected in series, dangerously high voltages may be generated.

To reduce potential electrical hazards during the installation process, it is adv

1

MODULE

Installation and User Manual

EN-MU-41 (4)-E