For the junction box to maintain its Class II safety standard, the cables must also be

Class II.

The ground wire must be

.To ground the modules, you must use a stainless steel

lug terminal

and a self-tapping screw between 4,2x4,5mm and 4,2x16mm. Esto

irá unido a un terminal de ojete semiaislado de 4mm .Ver imagen (10).

Make sure the lug terminal is placed between the wire and module frame. The wire

must fully clamped with the lug terminal and must make good contact with the frame.

There are two drill holes in the solar modules for this purpose, which are marked with a

ground connection (Earthing hole 4mm). View image of annex (11-12). The proper

torque values should be between 1,5 to 2Nm.

The photovoltaic system will be earthed according to the local and national regulations.

2

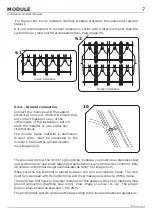

It is not recommended to connect modules in series with a total Voc higher than the

system Vmax .(View electrical characteristics). View image (9).

4mm

4mm

2

2

10

7

Series installation

Parallel installation

9.1

9.2

5.2.2.- Ground connection

Connect the modules and the support

structure to ground, which will ensure that

any current leakage to any of the

components of the installation will not

reach the installer or user under any

circumstances.

The module frame material is aluminium.

Ground wires must be connected to the

module

’

s frame at the ground location.

View imagen (10).

MODULE

Installation and User Manual

EN-MU-41 (4)-E