OPTIMUM GS MODULES INSTALLATION MANUAL

Page 13

Aplicaciones Técnicas de la Energía S.L. (ATERSA)

www.atersa.com – atersa@elecnor.com

Madrid (Spain) +34 915 178 452 - Valencia (Spain) +34 961 038 430

6.2.

Electrical Connections

6.2.1.

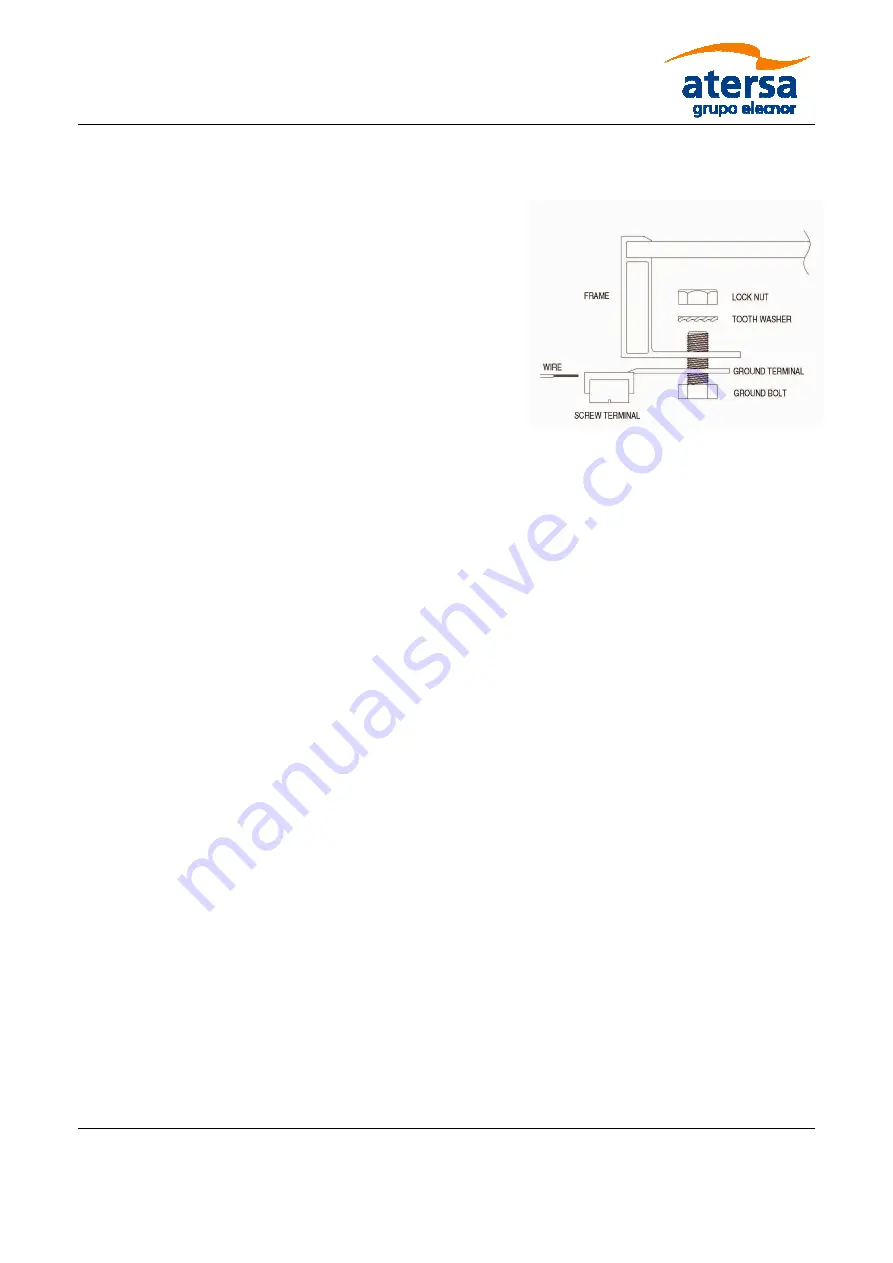

Equipment Grounding

•

To avoid the risk of electrical shock or fire, the

module frame should be grounded before the

electrical connection of the modules is

operated.

1. Stainless steel M5 - 304 bolt

2. Stainless steel M5 - 304 flat washer

3. Stainless steel M5 - 304 nut

•

The tightening torque

should be 2.1±0.1 Nm

•

A good connection between the grounding hardware is essential for an effective

ground. The anodization on a module frame provides a coating to minimize the

corrosion due to weather and it acts as a barrier that reduces the effectiveness of the

grounding connection. For an adequate ground, the grounding hardware should

penetrate the anodization layer.

Use the marked 5.1 mm grounding holes (5.1mm) to

ground the anodized frame.

•

10-12 AWG exposed copper wire is recommended as Ground wire.

•

The fastening system must be spliced with a cable that has a minimum diameter of

2.5mm

2

•

The copper wire cannot be attached directly to the aluminum.

6.2.2.

Bypass Diodes

Partial shading of an individual module can cause a reverse voltage across the shaded GES

SOLAR module. Current is then forced through the shaded area by the other modules.

When a bypass diode is wired in parallel with the series string, the forced current will flow

through the diode and bypass the shaded GS SOLAR module, thereby minimizing module

heating and array current losses.

In system utilizing a battery, blocking diodes are typically placed between the battery and the

GS module output to prevent battery discharge at night.

Diodes that are used as blocking diodes must: Have a Rated Average Forward Current [IF(AV)]

above

maximum system current at highest module operating temperature. Have a Rated

Repetitive Peak Reverse Voltage [VRRM]

above

maximum system voltage at lowest module

operating temperature.