www.atestgaz.pl

6

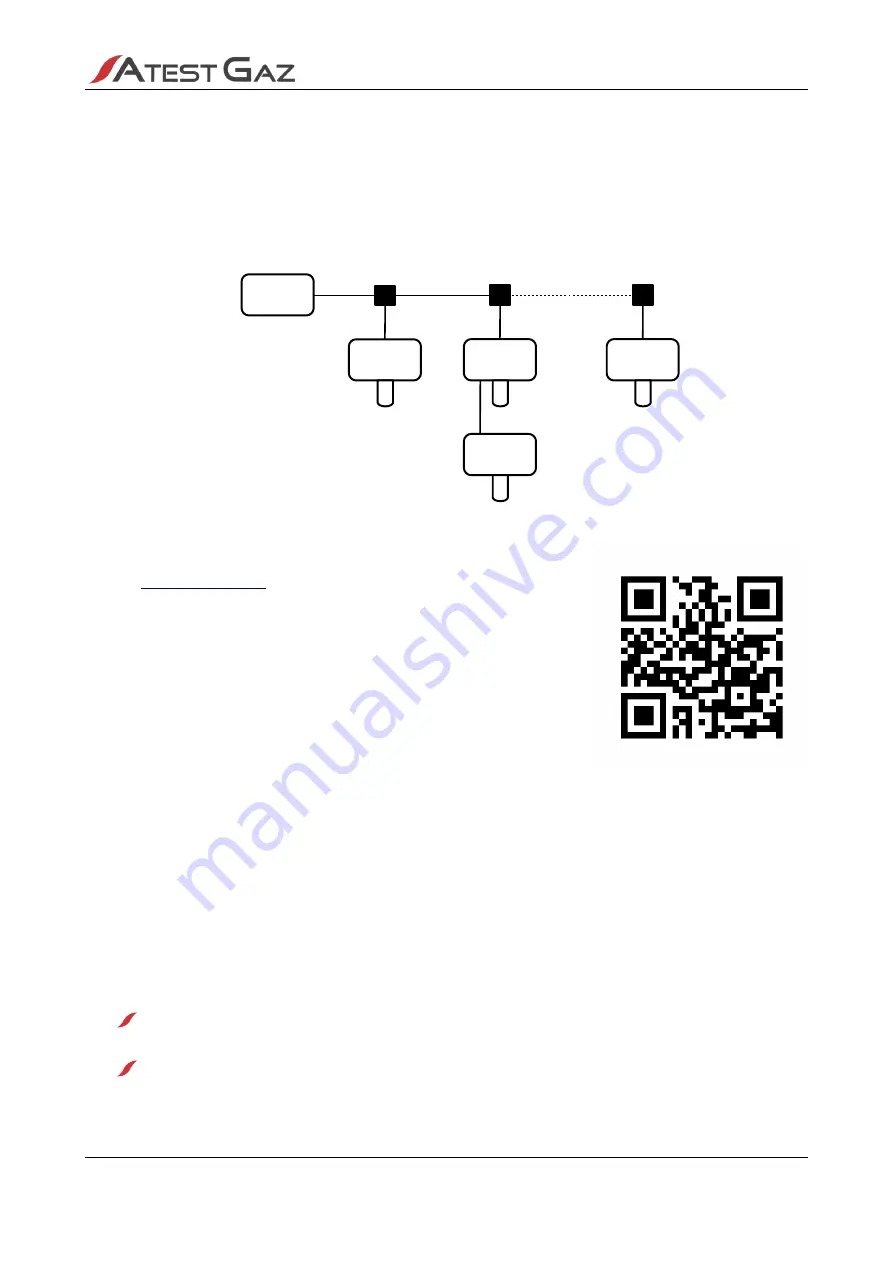

System architectures

The gas monitoring systems can be made up of independent gas detector Teta EcoWent or Teta EcoN or

coupled and collaborating pairs of detectors (Teta EcoWent with Teta MiniDet).

6.1

Data bus architecture

In this system gas detectors are connected to the bus via T-connectors S2.

Figure 3: Arrangement of gas detectors according to the data bus architecture

Detailed schematic diagrams in an editable format can be found on our

website

7

Lifetime cycle

7.1

Transportation

The device can be shipped in the same way as new equipment of that type. If the original package or

another protecting means (e.g. corks) is unavailable the conveyed equipment must be secured against

shocks, vibrations or moisture by means of adequate methods and material at the own responsibility of the

sender.

The device can be conveyed under environmental conditions as described in Table 5.

7.2

Installation

7.2.1

Deployment of gas detectors

Deployment of gas detectors must be determined by the system designed with consideration to the

following rules:

installation of CO detectors is recommended at the height of upper respiratory airways, i.e. circa

1.2 to 1.7 above the floor level,

NO

2

detectors should be installed at about 30 cm above the floor,

s. 11|20

User Manual: POD-046-ENG R01

Teta

MOD Control 1

Teta

EcoN

Teta

EcoWent

Teta

MiniDet

Teta

EcoWent