15

® Copyright ATH-Heinl GmbH & Co. KG, 2013, All rights reserved. / Misprint and technical changes reserved

/ Issue: 04/2012

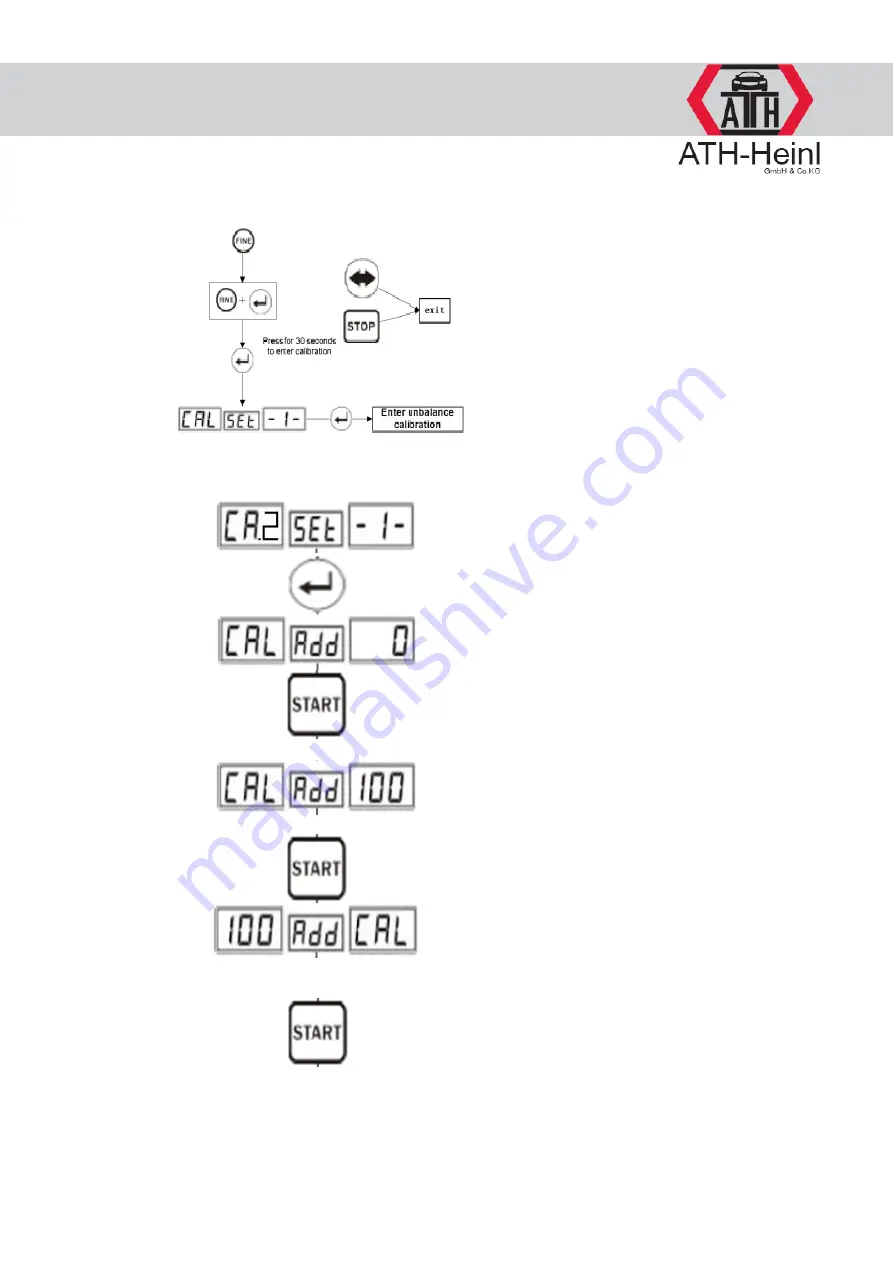

7.2 Service-calibration of wheel balancer ATH 1200 (Operation in both modes)

Fort he calibration must be clamped a

wheel with steel rim

≥ 15

inches (CAR-

mode) resp.

≥ 22,5

inchesl (TRUCK-

mode) and the wheel parameters

must be entered.

With adjacent key combination will be

called the standard calibration:

Press button FINE, then additionally

ENTER, release FINE, release

ENTER only after the display „CAL 1“

appears.

With the following key combination can

now be called the service calibration

:

Press ENTER, then FINE, hold both

keys until „CA.2“ appears in the

display, then release first ENTER and

then FINE.

After pressing the button ENTER

appears „CAL

-Add-

0“ in the display.

By pressing the button START the

balancing process for the calibration

will be started.

After the balancing process appears in

the display

„CAL

-Add-

100“. Turn the

wheel until all LED´s of the display

unbalance illuminate and fix the 100g

weight at the position 12 o´clock

outside.

By pressing the button START the

balancing process for the calibration

will be started newly.

After the balancing process appears

„100

-Add-

CAL“ in the display.

Remove

the 100 g weight outside. Turn the

wheel until all LED´s of the display

unbalance illuminate and fix the 100g

weight at the position 12 o´clock

inside.

By pressing the button START the

balancing process for the calibration

will be started newly.

After the balancing process is finished

the measuring data will be memorized

and the calibration is finished.