® Copyright by ATH-Heinl GmbH & Co. KG, 2014, All rights reserved /Misprint and technical changes reserved / Issue: 12/2014

- 16 -

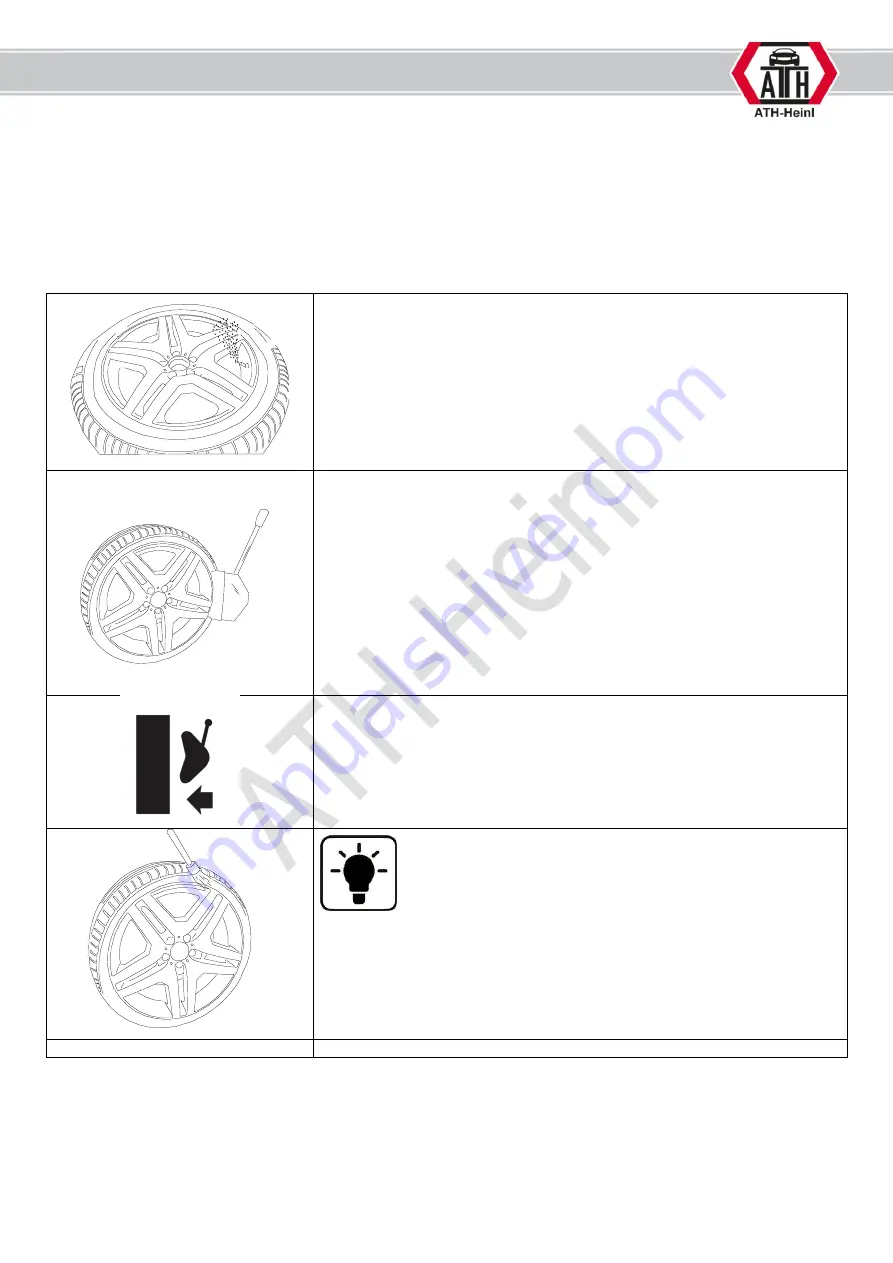

Bead breaking of a tire

Preparation

Before operating the machine check the following points:

- Checking of oil level, water level and air pressure of the maintenance unit.

- Checking, if the machine is correctly connected to the power supply.

Screw out the inlet of the wheel valve and let the air completely escape.

Turn respectively clamp the turntable in such a position so that no

components (cylinder, pneumatic screwings and so on) can be touched by the

tire.

Now turn the rim so that you can first break the bead of the outer side of the

rim.

Lay now the pressureless wheel lateral on the special rubber pad on the

machine housing.

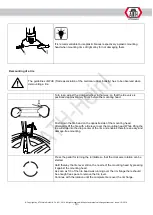

With the lever the bead shovel can be put on the outer side of the tire. For a

damage-free mounting the shovel must be positioned appr. 1 cm away from

the rim edge.

Press the pedal for the bead breaker until the tire is dismantled from the rim,

then IMMEDIATELY release the pedal.

Turn the wheel further and repeat the bead breaking process until the tire is

completely dismantled from the rim.

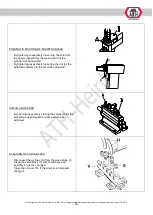

For making the following demounting of the tire easier respectively more

gentle for the tire and rim it is recommendable to coat the nascent tire and rim

parts while plunging the bead shovel in sufficiently with a marketable tire bead

lubricant.

Do only use approved lubricants!

Make the same with the second wheel side.