© Copyright ATH-Heinl GmbH & Co. KG, 2017, All rights reserved. / Printing errors and technical changing´s reserved / Version: 02/2017

- 44 -

Main board broken

Contact ATH-Service team

1

More causes of "bad" results:

-

Use of different adapters and resulting clamping errors.

When using adapters, please pay attention to the installation instructions.

-

Clamping by means of cones via a worn centre hole of the rim, differences of up to 10g may be

possible.

-

Unbalance of the tire on the vehicle can cause an imbalance on the brake drum or disc or worn

mounting holes in the rim or brake. In such a case, readjustment is advisable without first removing

the wheel.

Maintenance and service instructions

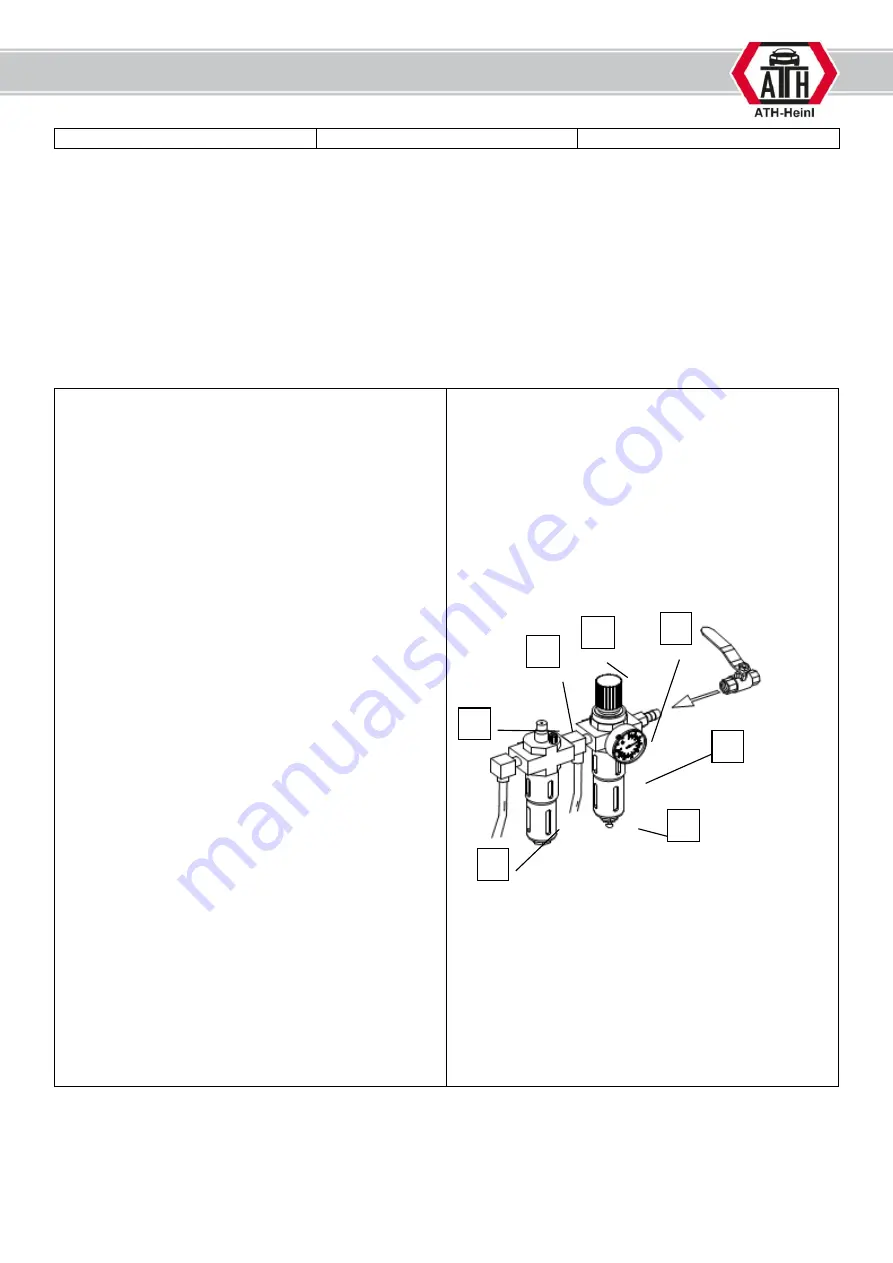

AIR MAINTENANCE UNIT

PRESSURE REGULATION:

-

Check the working pressure, which is indicated

in the manometer (1). This must correspond to

the technical data.

-

The working pressure can be set by means of

pressure regulator (A).

-

Pull up the pressure regulator to make

adjustments.

-

To increase the pressure in the machine, turn

the knob clockwise, to reduce it, turn it counter

clockwise.

OIL TANK

-

Check the oil level in the oil tank (3)

-

Remove the oil tank

-

Now fill the container with a pneumatic oil with

the viscosity SAE20

-

Check the injection quantity of the oil through

the inspection glass (4). The oiler functions

correctly when a drop of oil is automatically

injected into the compressed air system when

the trigger is pressed twice.

-

If this is not the case, the oil quantity to be

injected must be adjusted via the regulating

screw (C).

As a rule, the screw must be closed completely

clockwise and then reopened approximately ¼

to ½ turn by turning counter clockwise.

WATER SEPERATOR

-

Check the water level in the separator (2).

-

The water is drained by opening the valve (B).

Adjustment of drive belt tension

1.

Carefully remove the cover (weight tray).

A

B

C

1

2

4

3

Summary of Contents for ATH W82

Page 2: ...USER S MANUAL ATH W82 ...