® Copyright ATH-Heinl GmbH & Co. KG, All rights reserved / Misprints and technical changes reserved / As of: 2020-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 10 -

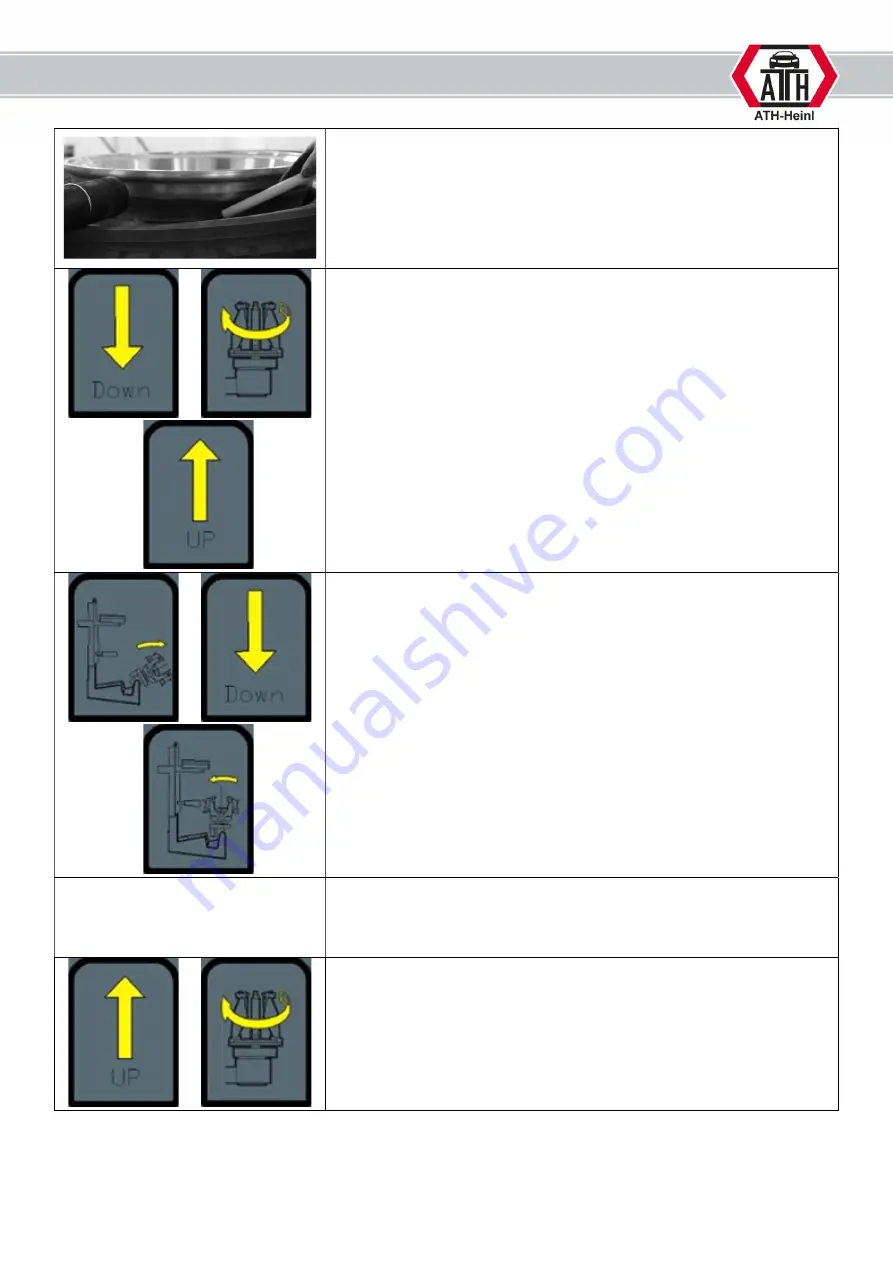

First, the tyre bead must be completely pressed off from both sides

of the rim with the bead breaker roller. During this process, the

mounting paste is applied to the rim and the tyre bead.

Start with the upper bead.

Place the bead breaker roller on the outside of the tyre. In order to

complete the assembly without any damage, the roller must be

positioned around 1 cm from the edge of the rim flange.

>

>

Operate the lever for lowering the assembly tower until the tyre is

released from the rim.

Begin the rotation process to release the entire tyre from the rim.

Operate the lever for lifting the assembly tower to release the

pressure from the tyre and allow for swivelling.

>

>

Swivel the wheel forward and lower the assembly tower until the

bead breaker roller is under the wheel. The wheel can then be

swivelled back towards the tower in order to press off the lower

bead.

Press off the lower tyre bead.

Place the bead breaker roller on the outside of the tyre. In order to

complete the assembly without any damage, the roller must be

positioned around 1 cm from the edge of the rim flange.

>

Operate the lever for lifting the assembly tower until the tyre is

released from the rim.

Begin the rotation process to release the entire tyre from the rim.

Then continue with the removal procedure.

Summary of Contents for M126

Page 3: ...BEDIENUNGSANLEITUNG ATH M126 ...

Page 47: ...OPERATING INSTRUCTIONS ATH M126 ...

Page 91: ...MANUEL D UTILISATION ATH M126 ...

Page 135: ...NÁVOD K OBSLUZE ATH M126 ...

Page 179: ...MANUAL DE INSTRUCCIONES ATH M126 ...

Page 223: ...BEDIENINGSHANDLEIDING ATH M126 ...

Page 267: ...INSTRUKCJA OBŁSUGI ATH M126 ...

Page 311: ...NÁVOD NA OBSLUHU ATH M126 ...