5

Gas-Fired Direct Vent Cast Iron Boilers – Field Assembly Instructions

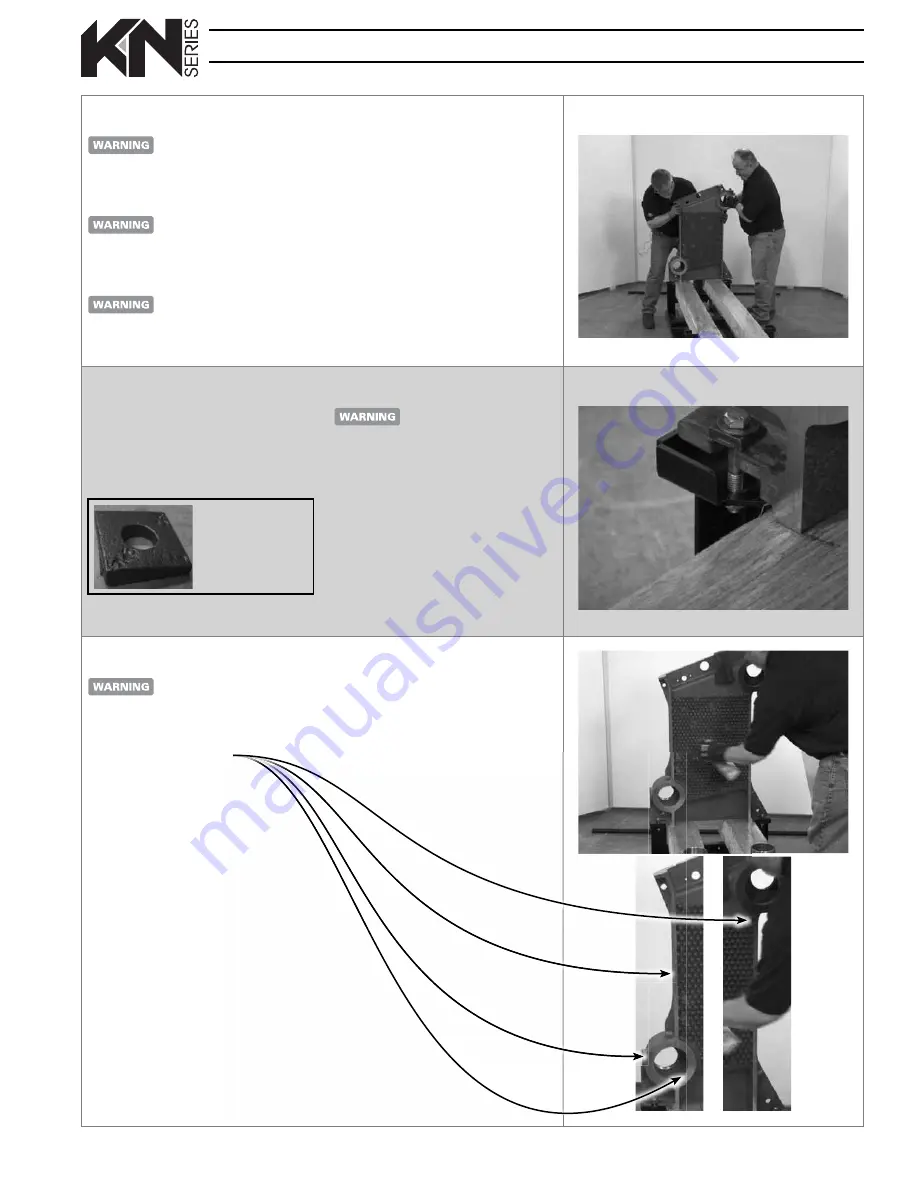

Step 4

Place the FRONT section

Use leather gloves when

lift ing or moving boiler

sections. Sections are heavy

and can cause severe personal

injury or death if mishandled.

Have someone support the

section during this step and

the next. Th e sections are

top-heavy and could easily

fall if not supported.

Handle all sections with

care to prevent any

damage to machined

surfaces.

1. Identify the FRONT section — its

lower nipple port is on the LEFT side

when looking at the inside of the

section, as in this photo.

2. Slide the front section to the end of

the base.

3. Lift into position and have someone

hold securely.

Step 5

Bolt front section to base

1. Use a 3/8 x 6 inch bolt, wedge, fl at

washer, split lock washer and nut on

each side as shown.

2. Point the wedge narrow edge toward

the section.

Wedge —

Point thin edge

toward the section.

Tighten bolt fi rmly, but DO

NOT over-tighten — the

cast iron fl ange could be

broken if too tight. Tighten

only until the split lock

washer has just fl att ened.

Th e bolt must be secure to

prevent movement of the

front section during the next

steps of assembly.

Step 6

Apply adhesive for ceramic fi ber fl ue baffl

e

DO NOT SPRAY adhesive

on the nipple port

machined surfaces

. Th is

would prevent proper sealing

with the silicone sealant

applied later.

1. Obtain the spray adhesive supplied in

the hardware box.

2. Spray ONLY the heat pin area of the

casting with the spray adhesive.

3. The adhesive is required to secure the

fl ue baffl

e (next step) in the fl ueway.

.

3. The adhesive is required to secure the

fl ue baffl

e (next step) in the fl ueway.