71

3.6.2

220V inverter (optional)

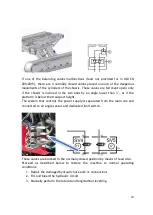

If the machine is equipped with a 220V inverter to power the outlet on the work

platform, the following safety devices will also be present:

1)

Insulation control device between the cables that go from the inverter to

the outlet on the work platform and the machine frame (Sentinel)

2)

Trip coil (triggered in the event of an alarm from the sentinel)

3)

Circuit breaker

4)

Auxiliary contact for insulation failure alarm (an alarm is generated if the

Sentinel has triggered the trip coil

5)

Exchange relay that switches the platform outlet connection from then

inverter to the plug placed under the ladder. The exchange occurs

automatically when 230V is detected on the plug.

Summary of Contents for 1090 EVO

Page 7: ...7...

Page 22: ...22...

Page 23: ...23...

Page 49: ...49 37 Combustion engine 38 Fuel tank 39 Bi levelling chassis 37 38...

Page 78: ...78...

Page 80: ...80...

Page 122: ...122 In this configuration the oil level must be as shown in the figure below A 60mm...

Page 144: ...144...

Page 145: ...145...

Page 146: ...146...

Page 147: ...147...

Page 148: ...148...

Page 149: ...149...

Page 150: ...150...

Page 151: ...151...

Page 152: ...152...

Page 161: ...161 8 ATTACHMENTS 8 1 Declaration of conformity...

Page 163: ...163 MANDATORY ROUTINE INSPECTIONS Date Observations Seal Signature...

Page 177: ...177 8 4 Hydraulic diagram See attachment 8 5 Wiring diagram See attachment...