PAGE

133

6.2

Maintenance: Details

The following points deal with the most significant specific cases

6.2.1

Checking and tightening screws, bolts, plug ring nuts

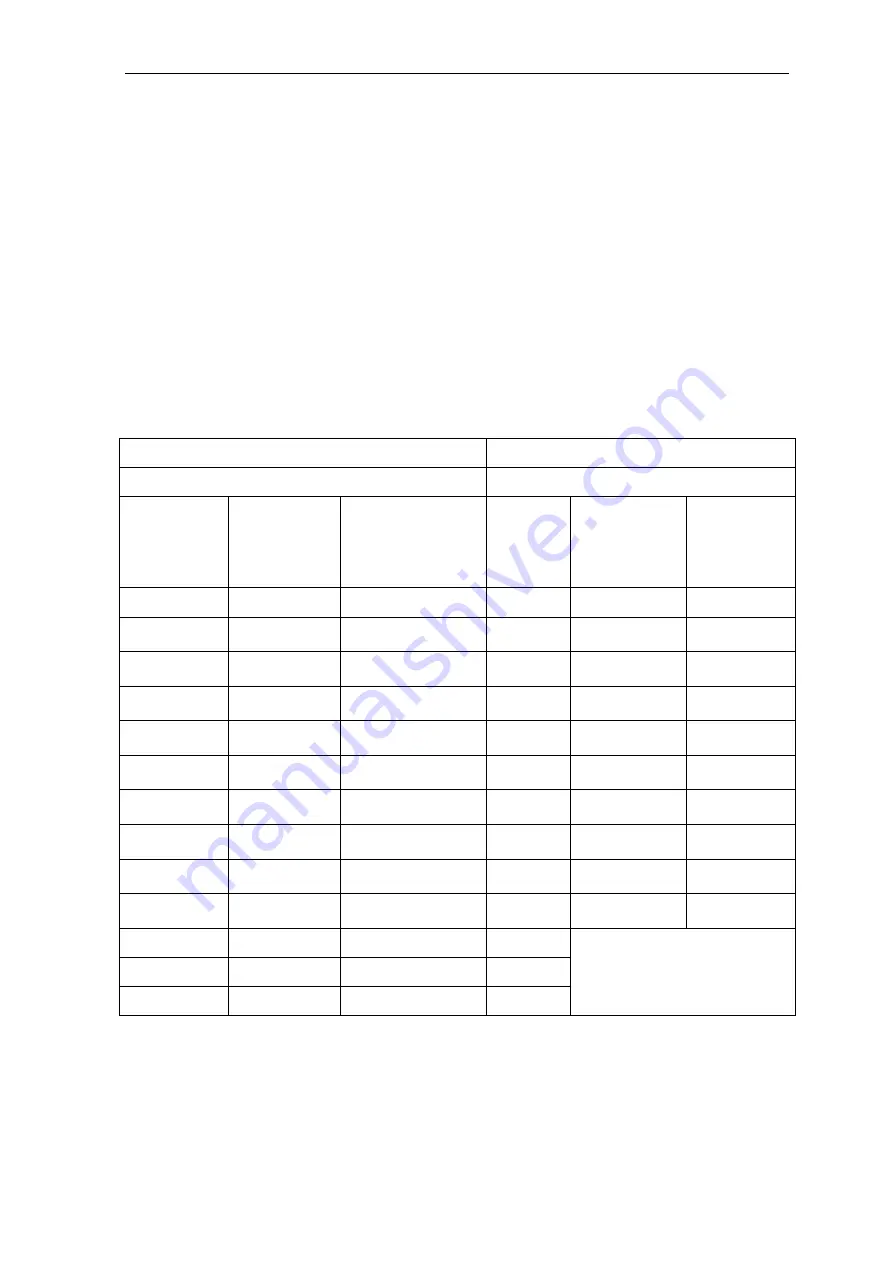

The operation of the following components must be checked. If necessary, the

parts must be tightened with the appropriate tools as indicated in the charts on

the following pages.

Clamping forces and tightening torque for bolts with a normal stroke metric

thread (

use the Ma

’

torque

)

Resistance class in accordance with DIN/ISO 898

8.8

Yielding point Rp 0,2 N/mm²

640 for <= M16 / 660 for >=M16

Metric thread

ISO

Cross-section

of the

powered zone

Cross section of

the thread

Clamping

force

For hydraulic

and electrical

torque wrench

Ma

’

= 0.9

MD* for the

wrench

DIN 13

AS mm²

A3 mm²

FM [kN]

MA [Nm]

MA

’

[Nm]

M12

84.3

76.2

38.5

87

78

M14

115

105

72

140

126

M16

157

144

91

215

193

M18

193

175

117

300

270

M20

245

225

146

430

387

M22

303

282

168

580

522

M24

353

324

221

740

666

M27

459

427

270

1100

990

M33

561

519

335

1500

1350

M36

694

647

395

Bolt determined by measuring

the yielding

M39

817

759

475

M42

976

913

542

Summary of Contents for 1470-HE EVO

Page 7: ...PAGE 7...

Page 12: ...PAGE 12 Work area on tracks Travel not allowed Maximum inclination allowed 2 5020 5490 7500...

Page 27: ...PAGE 27...

Page 28: ...PAGE 28...

Page 34: ...PAGE 34 Warning Do not tighten the fixing belts too much so as not to damage the eye bolts...

Page 50: ...PAGE 50 8 Extendible basket pedal...

Page 57: ...PAGE 57 38 Chassis and stabilisers...

Page 74: ...PAGE 74...

Page 76: ...PAGE 76...

Page 77: ...PAGE 77...

Page 80: ...PAGE 80...

Page 138: ...PAGE 138...

Page 160: ...PAGE 160...

Page 161: ...PAGE 161...

Page 162: ...PAGE 162...

Page 163: ...PAGE 163...

Page 164: ...PAGE 164...

Page 165: ...PAGE 165...

Page 166: ...PAGE 166...

Page 167: ...PAGE 167...

Page 168: ...PAGE 168...

Page 178: ...PAGE 178 MANDATORY ROUTINE INSPECTIONS Date Observations Seal Signature...

Page 191: ...PAGE 191 8 4 Hydraulic diagram See attachment 8 5 Wiring diagram See attachment...