PAGE

169

6.2.19

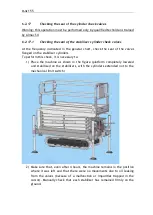

Track inspection and tensioning

Check track tension at the inspection frequency indicated in the general chart.

With the machine stabilised on the stabilisers and the tracks raised from the

ground, push the track downwards slightly, the deformation should be about 2

cm.

If the track sags and becomes too noisy as it moves, it must be tightened as

described below:

1)

Remove the guards (

1

)

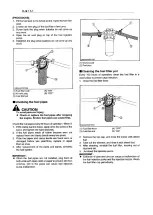

2)

For proper track tension use a tensioning kit (

2

) - not included - and pump

grease into the tensioning valve

(3

) until it reaches the pressure indicated

below. Consult the grease chart on the next pages for the type of grease

required.

Max pressure for track tensioning

Bar

300

Summary of Contents for 1470-HE EVO

Page 7: ...PAGE 7...

Page 12: ...PAGE 12 Work area on tracks Travel not allowed Maximum inclination allowed 2 5020 5490 7500...

Page 27: ...PAGE 27...

Page 28: ...PAGE 28...

Page 34: ...PAGE 34 Warning Do not tighten the fixing belts too much so as not to damage the eye bolts...

Page 50: ...PAGE 50 8 Extendible basket pedal...

Page 57: ...PAGE 57 38 Chassis and stabilisers...

Page 74: ...PAGE 74...

Page 76: ...PAGE 76...

Page 77: ...PAGE 77...

Page 80: ...PAGE 80...

Page 138: ...PAGE 138...

Page 160: ...PAGE 160...

Page 161: ...PAGE 161...

Page 162: ...PAGE 162...

Page 163: ...PAGE 163...

Page 164: ...PAGE 164...

Page 165: ...PAGE 165...

Page 166: ...PAGE 166...

Page 167: ...PAGE 167...

Page 168: ...PAGE 168...

Page 178: ...PAGE 178 MANDATORY ROUTINE INSPECTIONS Date Observations Seal Signature...

Page 191: ...PAGE 191 8 4 Hydraulic diagram See attachment 8 5 Wiring diagram See attachment...