14

Motor protection

The motor is equipped with a safety switch and switches off au-

tomatically when overloaded. After a cooling-down break (approx.

5 min), the motor may be restarted. Press the

1.

reset button (motor protection)

2.

green button I to restart.

Direction of rotation selector switch

Only actuate the direction of rotation selector switch

while the shredder is switched off.

Position

The material is drawn in by the cutting roller and shredded.

Position

The blades operate in the opposite direction and jammed material

is released.

Keep depressing the green button of the on/off switch once you

have placed the direction of rotation selector switch into the

position. The cutting roller is placed into the opposite direction. If

you release the on/off switch, the shredder automatically stops.

Hints

z

Large objects or pieces of wood may be removed after the

shredder has been operated several times both in cutting

and in release direction.

z

Use a tamper or hook to remove jammed objects from the

hopper or ejection slot.

Always wait until the shredder has come to a complete

standstill before restarting it.

Retaining basket

The integrated retaining basket is equipped with a locking

lever and a safety cut-out device.

L

Power off the device before attaching or removing the re-

taining basket.

@

Retaining basket locked and fixed connected to

the device.

@

Retaining basket unlocked and disconnected from

the device. The device cannot be powered up.

L

When the retaining basket is unlocked while the

device is operating the device is automatically cut

out.

W

W

o

o

r

r

k

k

i

i

n

n

g

g

w

w

i

i

t

t

h

h

t

t

h

h

e

e

g

g

a

a

r

r

d

d

e

e

n

n

s

s

h

h

r

r

e

e

d

d

d

d

e

e

r

r

Choose a working position alongside the equipment or behind

it. Never stand near the ejection opening.

Always keep away from the ejection area when starting the

machine.

Longer material that is protruding from the device could

spring back when it is drawn in by the blades! Observe safety

distance!

Never reach into the filling or ejection opening.

Keep your face and body away from the filling opening.

Never place hands, other parts of the body or clothing into the

filler funnel, ejection channel or in the vicinity of other moving

parts.

Check before powering the device up that:

−

no material residues are in the filling hopper,

−

the retaining basket is locked.

Do not tip or tilt the machine when the motor is running.

Make sure that the motor is free from waste material and

other material accumulation to protect it against damage and

to prevent fire.

When filling, be careful that no pieces of metal, stones, bottles

or other objects unintended for processing, enter the filling

hopper.

Immediately switch off the equipment and allow it to come to a

stop, if foreign objects enter the filling hopper or if the equip-

ment starts to make unusual noises or vibrates. Remove the

mains plug and carry out the following checks:

−

inspect for damage,

−

replace or repair damaged parts,

−

check the equipment and tighten loose parts.

You must not repair the equipment yourself if you are

unauthorized to do so.

What can I shred?

Yes:

•

all types of branches up to a max. diameter, depending on

wood species and freshness.

•

withered garden refuse which has lain a number of days.

Only shred in alternation with branches.

No:

•

glass, metal, plastic, plastic bags, stones, cloth, roots with soil

•

refuse which does not have a solid consistency, e. g. kitchen

waste

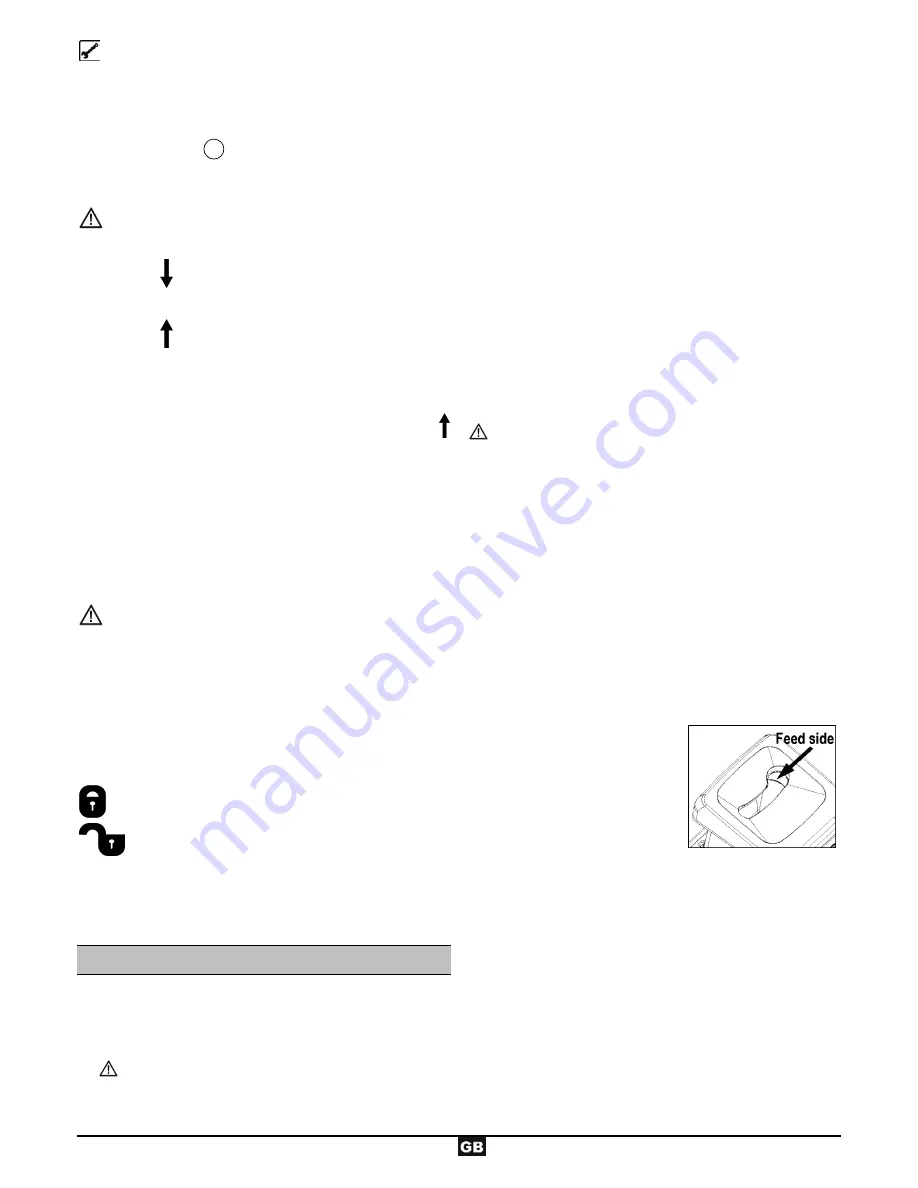

Special tips on shredding:

¾

Always fill the material to be

shredded into the filling hopper

from the right.

¾

Branches, twigs and wood

should be broken down immedi-

ately after they have been cut

−

material of this kinds gets

very hard when it is dry, and the maximum allowed branch

diameter to be processed has to be reduced.

¾

Remove any side shoots from branches with a large number

of twigs.

¾

How to shred garden waste with hight water content and a

tendency to clog

−

to prevent the machine from clogging, alternate waste with

wood containing material.

¾

Do not allow the shredded material to pile up too high in the

area of the ejection opening. This can lead to shredded mate-

rial blocking the ejection channel, and backing up to the filler

opening. Empty the retaining basket on a regular basis.

¾

Clean out the filler opening and ejection channel thoroughly if

the machine becomes blocked. Before doing this, switch the

motor off and disconnect the machine from the mains power

supply.