MAINTENANCE

23

1.

Unscrew the machine knob nut from the air filter cover. Now

remove the cover.

2.

Unscrew the wing nut from the air filter and remove the filter.

3.

Remove the foam filter from the paper filter.

4.

Inspect both air filter elements and replace them if

damaged. Paper elements must always be replaced at the

scheduled intervals.

5.

Clean the filter elements if they shall be reused.

Paper air filter element:

Tap the filter element several

times on a hard surface to remove the dust or blow it clean

with compressed air (not over 200 kPa). Never attempt to

brush off the dirt; brushing lets the dirt penetrate the fibres.

Foam air filter element:

Clean in warm soap water, rinse

thoroughly and dry well. Submerge the filter element in

clean engine oil and squeeze out the excess oil. The engine

smokes if the foam contains too much excess oil.

6.

Wipe off the dirt from the inside of the air filter bracket using

a wet rag. Make sure that no dirt enters the air line to the

carburettor.

7.

Place the foam element on the paper element and install the

assembled air filter again. Check to make sure that the seal

is installed under the air filter. Tighten the wings nuts of the

air filter.

8.

Install the air filter cover and tighten the machine knob nut of

the cover.

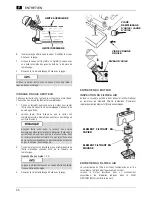

CLEANING THE FUEL FILTER

1.

Turn the fuel valve to OFF and unscrew the fuel filter and

O-ring.

Gasoline is highly flammable and explosive.

You may sustain burns or serious injuries when handling

gasoline.

z

Keep heat sources, sparks and fire away.

z

Handle gasoline only outdoors.

z

Immediately wipe off any spilled gasoline.

2.

Wash the fuel filter and the O-ring with a non-flammable

solvent and dry them thoroughly.

3.

Install the fuel filter with the O-ring. Tighten the fuel filter

firmly.

4.

Turn the fuel valve to ON and check for any leaks. Replace

the O-ring if it is leaking.

SPARK PLUG MAINTENANCE

Recommended spark plugs: F7RTC oder gleichwertig

.

Wrong spark plugs may damage the engine.

1.

Pull off the spark plug connector and clean the connector

area.

2.

Unscrew the spark plug with a spark plug wrench.

3.

Inspect the spark plug. Replace the spark plug if the

electrodes or the insulator are damaged.

4.

Measure the electrode gap with an appropriate feeler

gauge.

The gap must be 0.70 – 0.80 mm. Correct the gap, if

necessary, by carefully bending the outer electrode slightly.

5.

Carefully screw in the spark plug by hand to prevent

stripping the thread.

6.

Tighten the spark plug with the spark plug wrench after it is

seated.

If you are installing a used spark plug, tighten it by 1/8 –

1/4 turn.

If you are installing a new spark plug, tighten it by 1/2 – 1/4

turn.

A loose spark plug may overheat and damage the engine.

Tightening the spark plug too firmly may damage the thread

in the cylinder head.

7.

Put the spark plug connector back in place.

O-RING

FUEL FILTER

SPARK PLUG

WRENCH

0.7 – 0.8 mm

Summary of Contents for GHB 760 A

Page 110: ... NOTIZEN ...

Page 111: ......