−

There are no damage at the machine (see safety instruc-

tions).

−

All screws are tight.

L

Mains connection

Compare the voltage given on the machine model plate e.g.

230 V with the mains voltage and connect the machine to the

relevant and properly earthed plug.

Only use extension cables with sufficient core cross-section.

Mains fuse

Switzerland

UK

2200 W

16 A time-lag

10 A time-lag

13 A time-lag

2500 W

16 A time-lag

13 A time-lag

2800 W

16 A time-lag

13 A time-lag

14

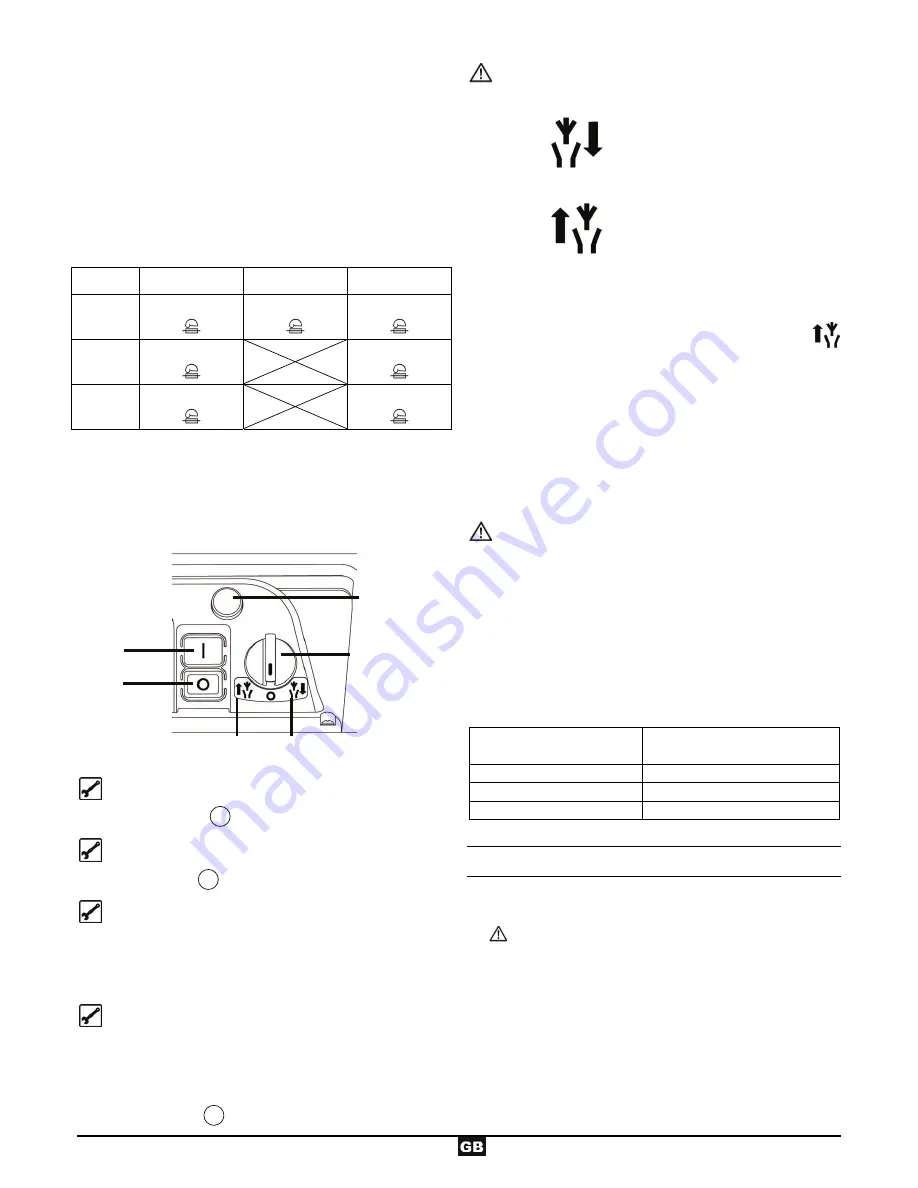

On / Off switch

Do not use any device where the switch can not be switched

on and off. Damaged switches must be repaired or replaced

immediately by the customer service.

Switch on

Press the green button I .

Switch off

Press the red button 0 .

Restart protection in case of power

failure

In case of a power failure, the device switches off automatically

(zero-voltage initiator). To restart, press the green button again.

Motor protection

The motor is equipped with a safety switch and switches off

automatically when overloaded. After a cooling-down break

(approx. 5 min), the motor may be restarted. Press the

1.

reset button (motor protection)

2.

green button I to restart.

Direction of rotation selector switch

Only actuate the direction of rotation selector switch

while the shredder is switched off.

Position

The material is drawn in by the cutting roller and shredded.

Position

The blades operate in the opposite direction and jammed material

is released.

Keep depressing the green button of the on/off switch once you

have placed the direction of rotation selector switch into the

position. The cutting roller is placed into the opposite direction. If

you release the on/off switch, the shredder automatically stops.

Hints

z

Large objects or pieces of wood may be removed after the

shredder has been operated several times both in cutting

and in release direction.

z

Use a tamper or hook to remove jammed objects from the

hopper or ejection slot.

Always wait until the shredder has come to a complete

standstill before restarting it.

Electrical mains supply impedance

Reset button

(motor protec-

tion)

When conditions in the electrical mains supply are un-favourable,

voltage reductions for short periods can occur during the process

of turning on the equipment, which can adversely affect other

equipment (e.g., the flickering of a lamp).

No breakdowns are to be expected if the maximum, electrical

mains supply impedances given in the table are met.

Power consumption P1 (W)

Electrical mains supply

impedance Zmax (W)

2200 0,21

2500 0,21

2800 0,19

W

W

o

o

r

r

k

k

i

i

n

n

g

g

w

w

i

i

t

t

h

h

t

t

h

h

e

e

g

g

a

a

r

r

d

d

e

e

n

n

s

s

h

h

r

r

e

e

d

d

d

d

e

e

r

r

Choose a

working position

alongside the equipment or be-

hind it. Never stand near the ejection opening.

Longer material that is protruding from the device could

spring back when it is drawn in by the blades!

Observe safety

distance!

Never

reach into the filling or ejection opening.

Keep your face and body away from the filling opening.

Never place hands, other parts of the body or clothing into the

filler funnel, ejection channel or in the vicinity of other moving

parts.

Check that no chopped residues are in the filling hopper be-

fore switching on the equipment.

Do not tip or tilt the machine when the motor is running.

ON

OFF

Reverse

Infeed

Direction of rota-

tion selector

switch

Summary of Contents for GHD 2200 -

Page 139: ...138 ...

Page 145: ...144 ...