Technical Manual & Parts Lists

14

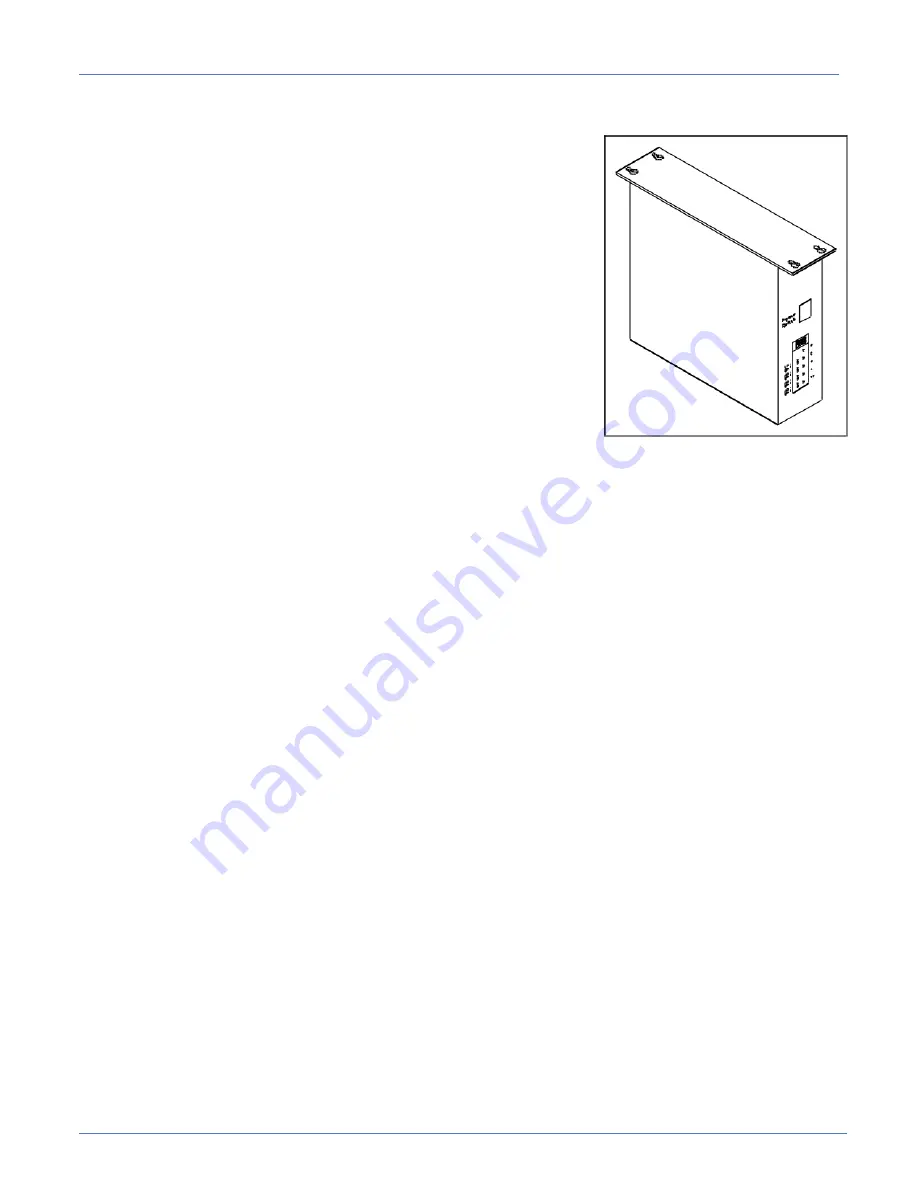

Efka Control Box

The sewing machine is powered by the Efka motor controller. It has

its own on/off switch which should be left on at all times. It also has

some small buttons and LED's on the front to indicate the enabled

functions. The only LED that should be on is the second to last from

the bottom which sets the control to stop the machine needle down at

neutral treadle and needle up after full heal back. The functions can be

changed upon power up or after a full heal back. The control box has

been programmed to operate specifically with the 1315A unit. If the

box is later replaced, the new box will need to be programmed

according to the included parameter list in order to function properly.

Notice that the sewing head does not stop at normal needle up

(lockstitch heads) position after full heal back, but stops at needle top

dead center to allow more room for loading thicker material

General Machine Maintenance

Daily

•

Clean machine at the end of every shift.

•

Clean lint etc. from the looper area on the sewing head.

•

Remove any threads wrapped around moving parts.

•

Wipe all photo eye lenses with a clean nonabrasive dry cloth.

•

Use a blow-off hose to get rid of excess lint, thread and other clippings.

•

Open conveyor door and inspect belt for debris and remove with broom or air hose.

•

Follow manufactures recommendations and guidelines for daily maintenance and

lubricating of sewing head.

Weekly

•

Check sewing head drive belt for tightness and condition.

•

Inspect reflective tape on handwheel and replace if dirty or worn.

•

Inspect conveyor bearings and remove thread and debris if needed.

Monthly

•

Inspect conveyor bearings and apply one shot of bearing grease to each bearing as needed.

From

the

library

of:

Diamond

Needle

Corp

Summary of Contents for 1315A

Page 2: ...From the library of Diamond Needle Corp ...

Page 44: ...Technical Manual Parts Lists 38 From the library of Diamond Needle Corp ...

Page 46: ...Technical Manual Parts Lists 40 From the library of Diamond Needle Corp ...

Page 48: ...Technical Manual Parts Lists 42 From the library of Diamond Needle Corp ...

Page 50: ...Technical Manual Parts Lists 44 From the library of Diamond Needle Corp ...

Page 52: ...Technical Manual Parts Lists 46 From the library of Diamond Needle Corp ...

Page 54: ...Technical Manual Parts Lists 48 From the library of Diamond Needle Corp ...

Page 56: ...Technical Manual Parts Lists 50 From the library of Diamond Needle Corp ...

Page 58: ...Technical Manual Parts Lists 52 From the library of Diamond Needle Corp ...

Page 60: ...Technical Manual Parts Lists 54 From the library of Diamond Needle Corp ...

Page 62: ...Technical Manual Parts Lists 56 From the library of Diamond Needle Corp ...

Page 64: ...Technical Manual Parts Lists 58 From the library of Diamond Needle Corp ...

Page 68: ...Technical Manual Parts Lists 62 From the library of Diamond Needle Corp ...

Page 70: ...Technical Manual Parts Lists 64 From the library of Diamond Needle Corp ...

Page 72: ...Technical Manual Parts Lists 66 From the library of Diamond Needle Corp ...

Page 76: ...Technical Manual Parts Lists 70 From the library of Diamond Needle Corp ...

Page 78: ...Technical Manual Parts Lists 72 From the library of Diamond Needle Corp ...

Page 80: ...Technical Manual Parts Lists 74 From the library of Diamond Needle Corp ...

Page 82: ...Technical Manual Parts Lists 76 From the library of Diamond Needle Corp ...

Page 84: ...Technical Manual Parts Lists 78 From the library of Diamond Needle Corp ...

Page 86: ...Technical Manual Parts Lists 80 From the library of Diamond Needle Corp ...

Page 94: ...Technical Manual Parts Lists 88 From the library of Diamond Needle Corp ...

Page 96: ...Technical Manual Parts Lists 90 From the library of Diamond Needle Corp ...

Page 98: ...Technical Manual Parts Lists 92 From the library of Diamond Needle Corp ...