Technical Manual & Parts Lists

18

General Machine Adjustments

Air Pressure

Set all air supply pressure regulators (Right to left):

Main Pressure:

70 PSI

This is the main regulator which limits maximum pressure to the solenoid valves and

cylinders.

Puller Pressure:

30 PSI

This is the Down pressure for the puller roller. Too much pressure may cause the

puller roller to stall. Too little pressure may cause the roller to not feed properly.

Ruffle Blade Pressure 10 PSI

This is the Down pressure for the ruffling blade. If it is set too low the ruffles will not

form properly due to slippage of the blade against the material. If it is set too high it will

press the stripper blade down to touch the bed plate of the machine and pinch the panel

causing difficulty in turning the corners.

Foot Sew Pressure:

15 PSI

This in the Down pressure on the presser foot while sewing straight (Not ruffling). It is

set for best feeding of the feed dog. The pressure while ruffling is set by the knob on top

of the sewing head. It is set to be very light so the ruffling blade can feed under the foot

and form the ruffles properly.

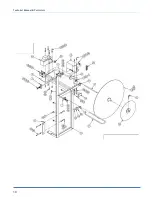

Sewing Head

See Manufactures manuals for normal adjustments and parts. The presser foot spring

pressure should be set very light so that the ruffling blade can feed under the foot while

ruffling. The Efka motor should be set for stopping needle down at neutral treadle to help

hold the ruffle in place while turning the corners. The auxiliary foot pressure cylinder

should be set to provide added foot pressure while sewing straight.

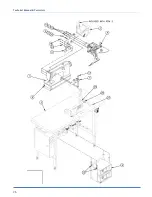

Ruffler Drive

Set the Ruffler blade position left to right. The slot in the Ruffler blade should align

with the sewing needle. Loosen the 4 clamp screws and adjust ruffler blade left or right as

needed.

Set the Ruffler blade IN position so that the front edge of the blade is even with the

needle when the ruffler drive is positioned at the IN sensor. To position the drive at the

sensor, press the manual ruffle button once and quickly tap the treadle or sew pedal. The

Ruffler should position itself at the IN sensor. Adjust the sensor position in its slot, press

the manual ruffle button to reset the ruffler and repeat the cycle to test the setting.

Set the Ruffler blade OUT position by turning the adjusting knob on the front cover of

the ruffler drive. This controls how big each ruffle will be. After making an adjustment,

always reset the ruffler by pressing the manual ruffle button twice.

The swing-out stripper blade protects the panel from the ruffler blade while ruffling so

that the panel does not get pleated by the blade. It should be positioned as close to the

Summary of Contents for 1335MDS

Page 2: ......

Page 27: ...Technical Manual Parts Lists 21 1335M Folder Spacer Reference Chart ...

Page 30: ...Technical Manual Parts Lists 24 ...

Page 32: ...Technical Manual Parts Lists 26 ...

Page 34: ...Technical Manual Parts Lists 28 ...

Page 36: ...Technical Manual Parts Lists 30 ...

Page 38: ...Technical Manual Parts Lists 32 ...

Page 40: ...Technical Manual Parts Lists 34 ...

Page 42: ...Technical Manual Parts Lists 36 ...

Page 44: ...Technical Manual Parts Lists 38 ...

Page 46: ...Technical Manual Parts Lists 40 ...

Page 48: ...Technical Manual Parts Lists 42 ...

Page 50: ...Technical Manual Parts Lists 44 ...

Page 52: ...Technical Manual Parts Lists 46 ...

Page 54: ...Technical Manual Parts Lists 48 ...

Page 56: ...Technical Manual Parts Lists 50 ...

Page 58: ...Technical Manual Parts Lists 52 ...

Page 60: ...Technical Manual Parts Lists 54 ...

Page 62: ...Technical Manual Parts Lists 56 ...

Page 66: ...Technical Manual Parts Lists 60 ...

Page 68: ...Technical Manual Parts Lists 62 ...

Page 70: ...Technical Manual Parts Lists 64 1335M 2400 Ball Screw and Nut Assembly 9000982 ...

Page 74: ...Technical Manual Parts Lists 68 ...

Page 76: ...Technical Manual Parts Lists 70 1335M PD Pneumatic Diagram 125618C ...

Page 77: ...Technical Manual Parts Lists 71 1335MDS PD Pneumatic Diagram 125670C ...

Page 78: ...Technical Manual Parts Lists 72 1335MDS WD Wiring Diagram 125650C ...

Page 79: ...Technical Manual Parts Lists 73 1335MDS WD1 Wiring Diagram 125573B ...

Page 80: ...Technical Manual Parts Lists 74 1335MDS WD2 Connection Diagram 125576B ...