Technical Manual & Parts Lists

16

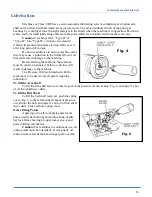

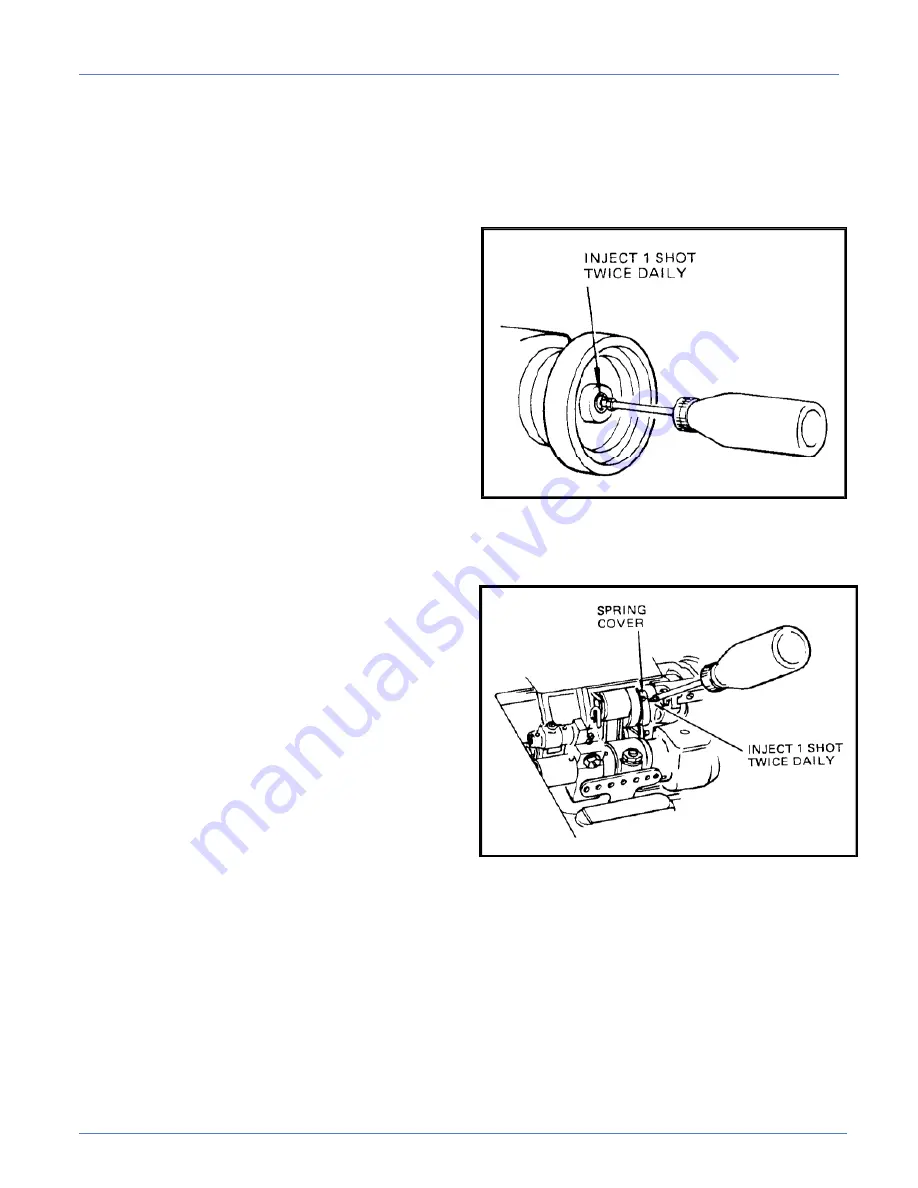

Fig. 4

Fig. 5

Lubrication

Machines of Class 300U have a semi-automatic lubricating system comprising of a hollow arm

shaft and a hollow bed shaft which act as oil reservoirs. The oil is distributed to all of the principal

bearings by centrifugal force through small jets in the shafts when the machine is in operation. Provision

is also made for hand lubricating other movable parts which are not lubricated from the reservoirs.

Caution:

User Singer Oil, “Type B” or

“Type D”. Use “Type D” oil when oil is desired

which will produce minimum stain on fabrics even

after long period of storage.

Do not use additives in sewing machine oil as

they may cause a reduction in the normal flow of oil

that can result in damage to the machine.

Before starting the machine, the machine

must be oiled as instructed. Failure to do this will

result in damage to the machine.

The Pressure Oil Can, furnished with the

machine is to be used to oil all points requiring

lubrication.

To Oil the Arm Shaft

To fill the arm shaft reservoir, insert spout of the pressure oil can in hole, Fig. 4, and inject 1 shot

of oil into shaft twice daily.

To Oil the Bed Shaft

To fill the bed shaft reservoir, push the spring

cover, Fig. 5, to the left and insert spout of pressure

oil can into the hole and inject 1 shot of oil into shaft

twice daily. Close oil hole spring cover.

Other Oiling Points

Applying oil to all work plate and arm oil

holes, needle bar bearings and connections, needle

bar rock frame bearings, looper rocker sleeve and

presser lifting mechanism.

Caution:

For machines in continuous use, all

oiling points must be oiled daily. Occasionally oil

tension release mechanism and looper pull-out rack.

Summary of Contents for 1345-6A

Page 2: ...Technical Manual Parts Lists ...

Page 21: ...Technical Manual Parts Lists 14 ...

Page 36: ...Technical Manual Parts Lists 29 ...

Page 38: ...Technical Manual Parts Lists 31 ...

Page 40: ...Technical Manual Parts Lists 33 ...

Page 42: ...Technical Manual Parts Lists 35 ...

Page 44: ...Technical Manual Parts Lists 37 ...

Page 46: ...Technical Manual Parts Lists 39 ...

Page 48: ...Technical Manual Parts Lists 41 ...

Page 50: ...Technical Manual Parts Lists 43 ...

Page 52: ...Technical Manual Parts Lists 45 ...

Page 54: ...Technical Manual Parts Lists 47 ...

Page 56: ...Technical Manual Parts Lists 49 ...

Page 60: ...Technical Manual Parts Lists 53 ...

Page 66: ...Technical Manual Parts Lists 59 ...

Page 68: ...Technical Manual Parts Lists 61 ...

Page 70: ...Technical Manual Parts Lists 63 ...

Page 72: ...Technical Manual Parts Lists 65 ...

Page 74: ...Technical Manual Parts Lists 67 ...

Page 76: ...Technical Manual Parts Lists 69 ...

Page 78: ...Technical Manual Parts Lists 71 ...

Page 80: ...Technical Manual Parts Lists 73 ...

Page 82: ...Technical Manual Parts Lists 75 ...

Page 87: ...Technical Manual Parts Lists 80 1345 6WD1 Wiring Diagram ...