too long time at one point will press the ballast

too deeply.

◆

Release the throttle lever when the machine is

lifted.

When taking a break

◆

Stop the machine during breaks.

◆

During all breaks, put the machine away so that

there is no risk for unintentional start.

Maintenance

Regular maintenance is a basic requirement for

the continued safe and efficient use of the

machine. Follow the maintenance instructions

carefully.

◆

Before starting maintenance on the machine,

clean it in order to avoid exposure to hazardous

substances. See “Dust and fume hazard”.

◆

Never use a pressure washer on the top cover

or inside the breaker housing.

◆

Use only authorised parts. Any damage or

malfunction caused by the use of unauthorised

parts is not covered by warranty or product

liability.

◆

When cleaning mechanical parts with solvent,

comply with appropriate health and safety

regulations and ensure there is satisfactory

ventilation.

◆

For major repair or service of the machine,

contact the nearest authorised workshop.

Perform service at your nearest authorized

workshop according to Atlas Copco's

recommended service intervals. The service

kits needed for each interval can be found in

the Spare parts list.

Every day

Before undertaking any maintenance or changing

the working tool, turn the machine off.

◆

Perform a general inspection and check that

there are no leaks and no damage, and change

if necessary.

◆

Check for damaged or loose wiring. If found,

contact an authorised workshop.

◆

Check that the tool retainer is not worn and that

it functions as it should. Never use the

equipment if you suspect that it is damaged.

◆

Check for wear in the tool chuck.

◆

Check the working tool, make sure that it is

sharp and not worn out. Check that the tool

shank is clean.

◆

Replace worn components in good time.

In order to ensure that the machine remains within

the stated vibration level values, the following

checks must be performed:

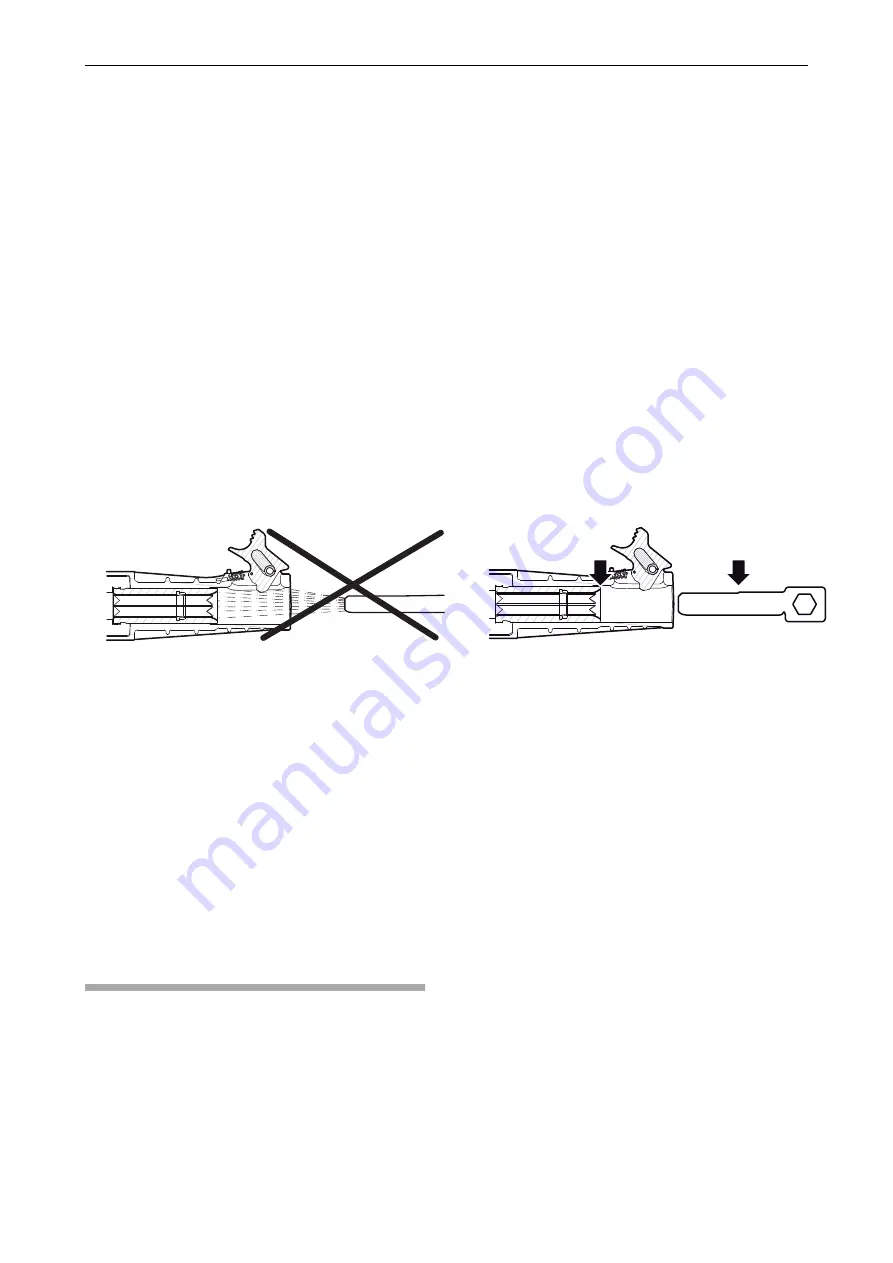

Wear check

If a working tool with a worn shank is used,

machine vibration will increase. Avoid such

vibration by checking for shank wear before

mounting the working tool on the machine.

◆

Use the shank gauge that corresponds to the

dimension of the working tools shank. If the

gauge can be inserted beyond point A in the

tool chuck (point B) then the tool chuck must be

replaced immediately.

A

B

Air filter check

A clogged air filter will eventually cause damage to

the engine. Check the air filter regularly.

1. Unscrew the air filter cover.

2. If the air filter is dirty, it must be replaced.

Never wash the air filter.

3. Clean filter container.

Spark plug check

If the spark plug electrodes are very dirty or

burned, replace the spark plug. The spark plug is

placed under the service cover, mounted in the

cylinder head. See the section "Main parts" for

position of the spark plug.

Only use Champion RCJ8 and make sure that the

electrode gap is 0.6-0.7 mm (0.024-0.028 in.)

before fitting the spark plug. Tighten the spark plug

using the correct tightening torque, see Spare

parts list.

Hammer mechanism oil check

The machine has a natural oil consumption and

the oil level in the impact unit should be checked

every day. The machine must be upright when

COBRA TTe

Safety and operating instructions

© Atlas Copco Airpower | 9800 1629 01 | 2018-01-01

Original instructions

17