•

Rotor:

Check that the end faces do not have any marks or burrs.

Check that the splines are not worn or cracked. Check that there are

no cracks at the holes for the plugs.

•

Cylinder:

Check that the bore is not scored or scratched. If these are

shallow, polish with a fine grinding cloth. Clean thoroughly.

Lubrication

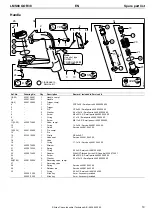

Lubrication guide

Air and motor lub-

rication

Impact mechanism

General purpose

grease

Brand

Energol E46

Energrease LS-EP2

BP

Spheerol EP L2

Castrol

Arox EP46

Beacon EP2

Esso

Chopin 46

Rembrandt EP2

Q8

Almo oil 525

Mobilegrease XHP

222

Mobil

Torcula 32

Alvania Grease RL 2

Alvania EP2

Shell

Aries 32

Multifak EP2

Texaco

Molycote

Filling of oil for Motor

Fill up with appr.

10

ml of oil. Please see Lubrication guide for recom-

mended oil.

s005400

Lubrication of impact mechanism

s000150

Spread a layer of grease on all sliding and impact surfaces. Use the rest

of the grease, approximately half the amount, inside the cavity of the

hammer and on the driver flange. Total grease amount

35

ml.

13

© Atlas Copco Industrial Technique AB - 9836 6502 00

Service

EN

LMS88 GOR38