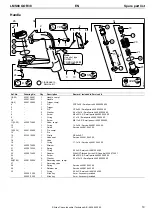

Test data

Test on Tension tester (Skidmore-Wilhelm)

s005371

Test performance:

Test equipment according to the tables below.

Assemble selected test bolt set in the tester ensuring that threads and

pressure faces are well lubricated with Molycote Longterm W2 or sim-

ilar molybdenum disulphide lubricant.

Make 3 tightenings and check that the minimum tension can be

reached.

Test conditions:

Air pressure = 6.3 bar (90 psi) dynamic.

Test result

Test hose (3 m)

inner diam.

Min. *

Free speed

Tightening

time

Min.

Tension

Bolt size

Tester

Model

6.3 mm (1/4”)

11000 rpm

2 s

34 kN

5/8”

Skidmore-Wilhelm model J

LMS08 HR10

6.3 mm (1/4”)

11000 rpm

2 s

21 kN

5/8”

Skidmore-Wilhelm model J

LMS08 HR42

6.3 mm (1/4”)

11000 rpm

2 s

33 kN

5/8”

Skidmore-Wilhelm model J

LMS08 SR10

6.3 mm (1/4”)

11000 rpm

2 s

19 kN

5/8”

Skidmore-Wilhelm model J

LMS08 SR42

10 mm (3/8”)

7000 rpm

2 s

39 kN

7/8”

Skidmore-Wilhelm model J

LMS18 HR10

10 mm (3/8”)

7000 rpm

2 s

53 kN

7/8”

Skidmore-Wilhelm model J

LMS18 HR13

10 mm (3/8”)

8000 rpm

2 s

83 kN

3/4”

Skidmore-Wilhelm model RL

LMS28 HR13

10 mm (3/8”)

6800 rpm

2 s

110 kN

1”

Skidmore-Wilhelm model RL

LMS38 HR13

12.5 mm (1/2”)

5500 rpm

3 s

161 kN

1”

Skidmore-Wilhelm model RL

LMS48 HR20

12.5 mm (1/2”)

4700 rpm

3 s

260 kN

1 1/4”

Skidmore-Wilhelm model H

LMS58 HR20

12.5 mm (1/2”)

4700 rpm

3 s

270 kN

1 1/4”

Skidmore-Wilhelm model H

LMS58 HR25

16 mm (5/8”)

4200 rpm

4 s

470 kN

1 1/2”

Skidmore-Wilhelm model H

LMS68

16 mm (5/8”)

3200 rpm

6 s

660 kN

2”

Skidmore-Wilhelm model K

LMS88

* = If Free speed is to low: check silencer for clogged filters.

15

© Atlas Copco Industrial Technique AB - 9836 6502 00

Service

EN

LMS88 GOR38