Installation requirement

General

The machine is designed for a working pressure (e) of 6.3 - 7 bar (max.) = 630 - 700 kPa (90 - 102 psi).

If the compressed air line pressure is higher than 7 bar it is preferable reduced with a pressure regulator of

the type Atlas Copco REG.

The Atlas Copco Air Line Test equipment is suitable for checking of air pressure and airflow at the installation

point (please see AirLine Accessories in our main catalogue).

The machine can operate at a lower working pressure. Maximum torque will be reduced at lower pressures.

A

If frequent used for tightening or loosening that need longer time than 3-5 seconds, a larger wrench

should be used. Otherwise the servicelife of the impact mechanism will be reduced.

To avoid pressure drop use recommended hosesize, length, and connections. For more information please read

Atlas Copco Airline Installations, Ordering No. 9833 1191 01.

Air quality

• For optimum performance and maximum machine life we recommend the use of compressed air with a

maximum dew point of +10°C. We also recommend the installation of an Atlas Copco refrigeration-type air

dryer.

• Use a separate air filter of type Atlas Copco FIL. This filter removes solid particles larger than 15 microns

and also removes more than 90 % of liquid water. The filter must be installed as close as possible to the

machine/equipment and prior to any other air preparation unit such as REG or DIM (please see Air Line

Accessories in our main catalogue). Blow out the hose before connecting.

Models which need air lubrication:

• The compressed air must contain a small quantity of oil.

We strongly recommend that you install an Atlas Copco oil-fog lubricator (DIM). This should be set according

to air consumption by the air line tool according to the following formula:

L

= Air consumption (litre/s).

(May be found in our sales literature).

D

= Number of drops per min (1 drop = 15 mm

3

)

L* 0.2 = D

this applies to the use of long work cycle air line tools. A single point lubricator type Atlas Copco Dosol can

also be used for tools with short running cycles.

Information about Dosol settings may be found under Air Line Accessories in our main catalogue.

Lubrication-free models:

• In the case of lubrication-free tools it is up to the customer to decide on the peripheral equipment to be used.

However, it is no disadvantage if the compressed air contains a small quantity of oil e.g. supplied from a fog

lubricator (DIM) or Dosol system. This does not apply to turbine tools, which should be kept oil free.

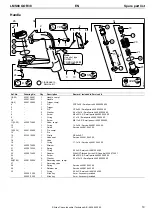

Installation proposal

Choosing the correct couplings, hose and clamps can be a troublesome digging into details. To save your time

and to ensure correct capacity of the airline installation, from the tapping point to the tool, we offer you an in-

stallation proposal.

5

© Atlas Copco Industrial Technique AB - 9836 6502 00

Installation

EN

LMS88 GOR38