Instruction book

2920 1521 00

34

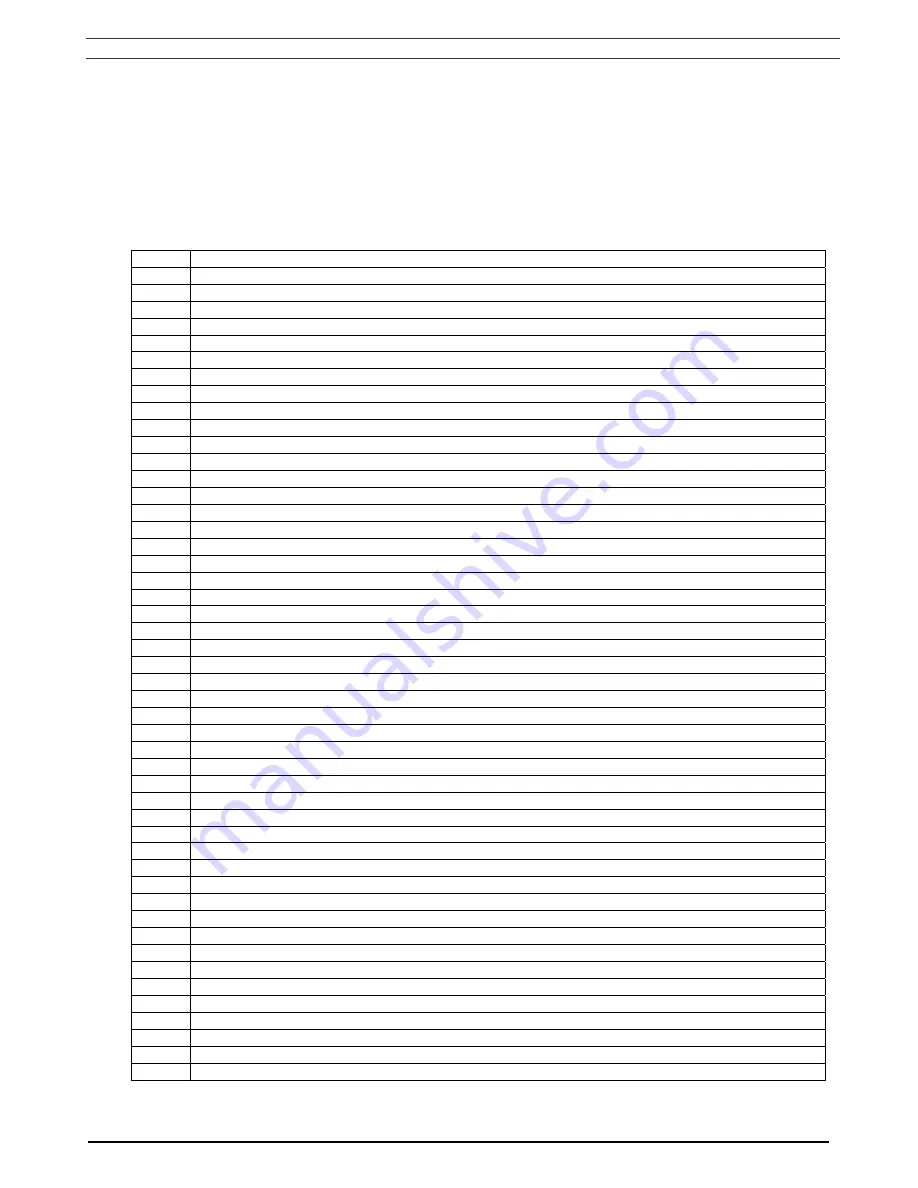

6 PROBLEM SOLVING

Before carrying out any maintenance or repair:

1.

Stop the compressor, switch off the voltage and open the isolating switch.

2.

Close the air outlet valve (2-Figs. 1.2/1.4 or 3-Figs. 1.5/1.6) and open the manual drain valve: valve

(1-Fig. 1.9) on Multi or the valve underneath the air receiver, if provided.

1

Compressor does not start

a Loose

connection

a

Have electrical connections checked

b

Receiver pressure too high

b

Compressor will start when the net pressure drops to the minimum pressure

2

Safety valve blows

a

Safety valve opens too soon

a

Replace valve

3

Compressor capacity or pressure below normal

a

Air consumption exceeds capacity of compressor

a

Check equipment connected

b

Choked air filter

b

Remove and check filter. Replace if necessary

c

Safety valve leaking

c Replace

valve

d

Drive belt(s) slipping

d

Check condition of belt(s). Correct or replace as required

4

Compressor module overheating / compressor shut down by its air temperature switch

a Insufficient

compressor

cooling

a

Improve ventilation of compressor room.

b

Cooling fan out of order

b Check

and

correct

On SF Full-Feature also:

5

Pressure dewpoint too high

a

Shortage of refrigerant

a

Have circuit repaired or recharged

b

Refrigerant compressor does not run

b See

7

c

Condenser pressure is too high

c See

6

6

Condenser pressure too high or too low

a

Fan control switch out of order

a

Have switch replaced

b

Condenser fan motor out of order

b

Have fan motor inspected

c

Ambient temperature too high

c

Improve ventilation. If necessary, draw the cooling air from a cooler room

d

Condenser externally clogged

d Clean

condenser

7

Motor of refrigerant compressor stops or does not start

a

Thermal protection of the motor has tripped

a Compressor

will

restart when the motor windings have cooled down