►

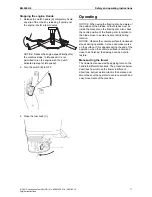

Release the filler cap slowly to let pressure

escape.

►

Never overfill the fuel tank.

►

Make sure the filler cap is screwed on when the

machine is used.

►

Avoid spilling fuel on the machine, wipe off any

spilled fuel.

►

Check regularly for fuel leaks. Never use the

machine if it is leaking fuel.

►

Never use the machine in the proximity of material

that can generate sparks. Remove all hot or

spark-generating devices before starting the

machine.

►

Never smoke when filling the fuel tank or when

working with the machine or servicing it.

►

Only store fuel in a container that is specially

constructed and approved for the purpose.

►

Consumed fuel and oil containers must be taken

care of and returned to the retailer.

►

Never use your fingers to check for fluid leaks.

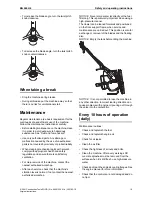

WARNING Unexpected movements

The machine is exposed to heavy strains during

operation. If the machine breaks or gets stuck, there

may be sudden and unexpected movement that can

cause injuries.

►

Always inspect the machine prior to use. Never

use the machine if you suspect that it is damaged.

►

Make sure that the handle is clean and free of

grease and oil.

►

Keep your feet away from the machine.

►

Never sit on the machine.

►

Never strike or abuse the machine.

►

Pay attention and look at what you are doing.

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when

using the machine may cause serious and permanent

respiratory disease, illness, or other bodily injury (for

example, silicosis or other irreversible lung disease

that can be fatal, cancer, birth defects, and/or skin

inflammation).

Some dusts and fumes created by compaction work

contain substances known to the State of California

and other authorities to cause respiratory disease,

cancer, birth defects, or other reproductive harm.

Some examples of such substances are:

●

Crystalline silica, cement, and other masonry

products.

●

Arsenic and chromium from chemically-treated

rubber.

●

Lead from lead-based paints.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to determine

if there is dust or fumes are the air.

To reduce the risk of exposure to dust and fumes,

do all of the following:

►

Perform site-specific risk assessment. The risk

assessment must include dust and fumes created

by the use of the machine and the potential for

disturbing existing dust.

►

Use proper engineering controls to minimize the

amount of dust and fumes in the air and to

minimize build-up on equipment, surfaces,

clothing, and body parts. Examples of controls

include: exhaust ventilation and dust collection

systems, water sprays, and wet drilling. Control

dusts and fumes at the source where possible.

Make sure that controls are properly installed,

maintained and correctly used.

►

Wear, maintain and correctly use respiratory

protection as instructed by your employer and as

required by occupational health and safety

regulations. The respiratory protection must be

effective for the type of substance at issue (and if

applicable, approved by relevant governmental

authority).

►

Work in a well ventilated area.

►

If the machine has an exhaust, direct the exhaust

so as to reduce disturbance of dust in a dust filled

environment.

►

Operate and maintain the machine as

recommended in the operating and safety

instructions

►

Wear washable or disposable protective clothes

at the worksite, and shower and change into clean

clothes before leaving the worksite to reduce

exposure of dust and fumes to yourself, other

persons, cars, homes, and other areas.

7

© 2051 Construction Tools EOOD | No. 9800 1224 01b | 2051-05-18

Original instructions

Safety and operating instructions

BG 240 H4