F 70.18 10

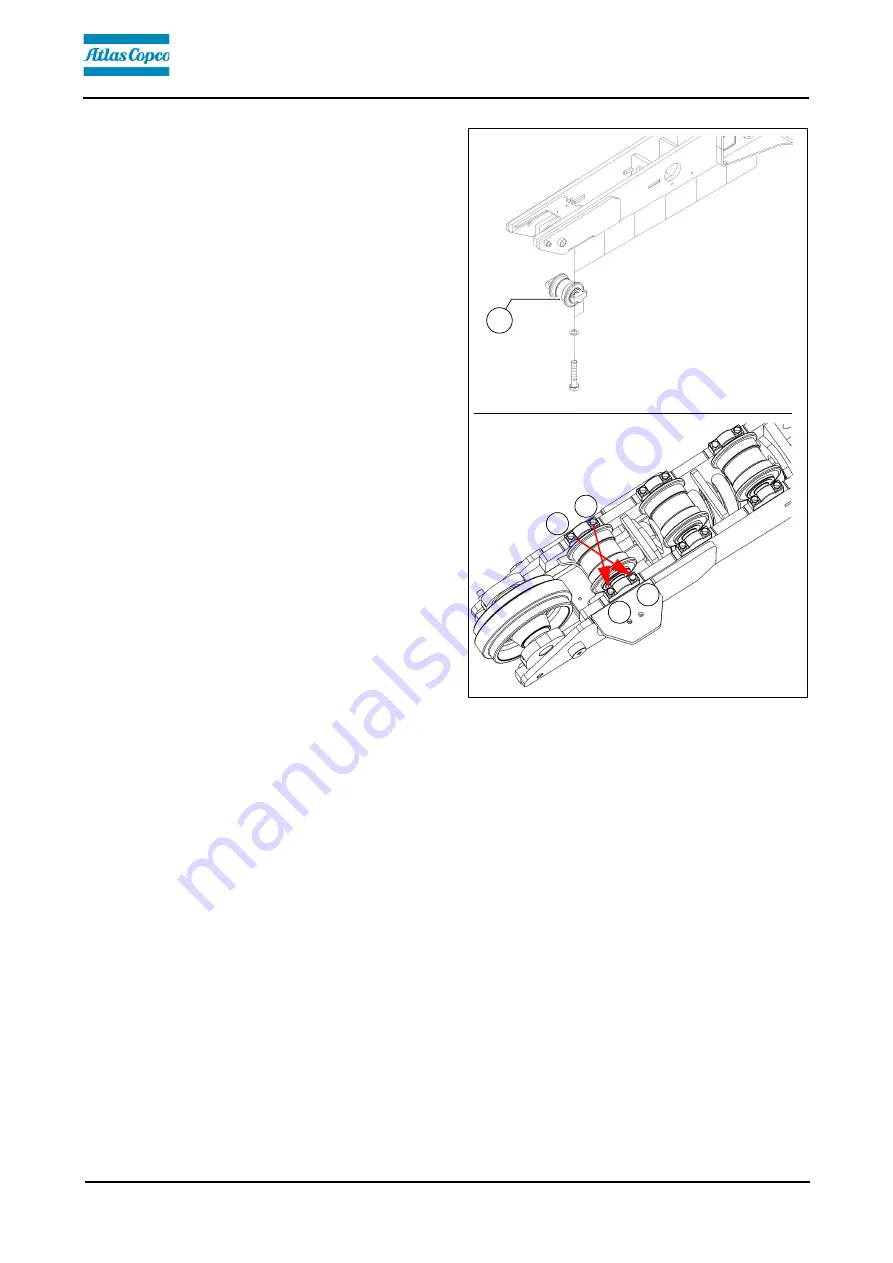

Rollers (3)

m

Rollers with damaged surfaces or which

are leaking should be replaced immedi-

ately!

- Relieving the caterpillar chain:

- Raise the track chassis using suitable

lifting equipment and remove adher-

ing dirt.

f

Observe the safety measures when rais-

ing and securing loads!

- Remove the defective roller.

- Install the new roller using new as-

sembly parts.

A

Use the bolt locking device stated in the

spare parts catalogue in accordance

with the manufacturer’s instructions.

- Tighten the bolts without applying sig-

nificant torque.

- Tighten the bolts diagonally to the re-

quired torque.

- Tighten to the following torques:

- Rollers (A): 83 Nm

m

Check that each bolt has attained the full tightening torque!

- Lower the track chassis and tension the caterpillar chain properly.

A

1

3

4

2

Summary of Contents for Dynapac F1800C

Page 2: ...www atlascopco com...

Page 10: ...8...

Page 24: ...A 2...

Page 32: ...B 8 4 Safety devices 5 7 11 4 5 6 7 3 1 2 9 12 10 10 8...

Page 43: ...B 19 71 70 40 41 42 xxxxxxxxxxxxxxxxx 7 7 51 53...

Page 78: ...D 10 18 4 10 15 16 19 18 20 17 14 11 12 10...

Page 80: ...D 10 18 6 10 15 16 19 18 20 17 14 11 12 10...

Page 82: ...D 10 18 8 10 15 16 19 18 20 17 14 11 12 10...

Page 84: ...D 10 18 10 24 23...

Page 86: ...D 10 18 12 26 25...

Page 88: ...D 10 18 14 28 27 30 29...

Page 90: ...D 10 18 16 28 27 30 29...

Page 92: ...D 10 18 18 32 31...

Page 94: ...D 10 18 20 34 33...

Page 96: ...D 10 18 22 35...

Page 98: ...D 10 18 24 37 36...

Page 100: ...D 10 18 26 38...

Page 102: ...D 10 18 28 39...

Page 104: ...D 10 18 30 40...

Page 106: ...D 10 18 32 41...

Page 108: ...D 10 18 34 43 42...

Page 110: ...D 10 18 36 44 45 46 47...

Page 112: ...D 10 18 38 48 50 51 49...

Page 114: ...D 10 18 40 48 50 51 49...

Page 116: ...D 10 18 42 52 53 54 55 56 57...

Page 118: ...D 10 18 44 60 64 63 65 67 62 61 66 68...

Page 120: ...D 10 18 46 60 64 63 65 67 62 61 66 68...

Page 124: ...D 10 18 50 90 91 92 95 94 96 93 97 97...

Page 126: ...D 10 18 52...

Page 129: ...D 30 18 3 Control platform telescoping seat consoles 10 B A B 11 6 4 5 2 8 A 9 7 12...

Page 162: ...D 30 18 36...

Page 167: ...D 40 18 5 1 3 10 2 8 6 6 4 5 7 9...

Page 170: ...D 40 18 8 1 3 10 2 8 6 4 5 7 9 6...

Page 173: ...D 40 18 11 2 3 4 1...

Page 175: ...D 40 18 13 1 2 3 5 7 6...

Page 177: ...D 40 18 15 2 2 3 1 6 5 4...

Page 181: ...D 40 18 19 1 A 3 2 4...

Page 183: ...D 40 18 21 1 2 5 6 7 4 11 10 3 9 8 12...

Page 186: ...D 40 18 24 1 2...

Page 188: ...D 40 18 26 1 3 14 9 2 9 7 6 4 10 12 11 13 5 15 5 8 4...

Page 190: ...D 40 18 28 2 Malfunctions 2 1 Error code query for engine 3 1 2...

Page 198: ...D 40 18 36...

Page 215: ...F 31 18 1 F 31 18 Maintenance conveyor 1 Maintenance conveyor...

Page 222: ...F 31 18 8...

Page 223: ...F 40 18 1 F 40 18Maintenance auger assembly 1 Maintenance auger assembly...

Page 247: ...F 60 18 1 F 60 18 Maintenance hydraulic system 1 Maintenance hydraulic system...

Page 262: ...F 60 18 16...

Page 263: ...F 70 18 1 F 70 18 Maintenance drive units 1 Maintenance drive units...

Page 275: ...F 82 18 1 F 82 18 Maintenance electrical system 1 Maintenance electrical system...

Page 290: ...F 82 18 16...

Page 298: ...F 90 18 8...

Page 299: ...F 100 1 F 100 Tests stopping 1 Tests checks cleaning stopping...

Page 308: ...F 100 10...

Page 310: ...F 110 18 2 2 6 6 1 7 3 4 5...

Page 316: ...F 110 18 8...

Page 318: ...www atlascopco com...