F 1.0 1

F_1

.0_

01_G

B.

fm

1-

2

F 1.0

Maintenance

1

Notes regarding safety

f

Maintenance work: Maintenance work may only be carried out when the engine is

at a standstill.

Secure the paver finisher and the attachments against inadvertent starting before be-

ginning any maintenance work:

- Set the drive lever to the center position and the speed preselector to zero.

- Remove the traction drive fuse from the operating panel.

- Remove the ignition key and the battery main switch.

f

Lifting and jacking up: Secure lifted machine parts (e.g. screed or hopper) against

lowering by means of mechanical supports.

m

Spare parts: Use only approved parts and install them according to the specifica-

tions! If in doubt, contact the manufacturer!

f

Re-commissioning: Mount all protective devices before re-commissioning the paver

finisher.

f

Cleaning: Cleaning must not be carried out while the engine is running.

Do not use any inflammable substances (such as petrol).

Avoid directly cleaning electrical parts and insulation material with a steam jet; cover

them up beforehand.

f

Working in closed environments: Exhaust fumes must be led into the open. Pro-

pane gas bottles must not be stored in closed rooms.

m

In addition to these Maintenance Instructions, the Maintenance Instructions of the en-

gine manufacturer must always also be observed. All other maintenance work and in-

tervals noted in these instructions are also binding.

A

The instructions for the maintenance of the optional equipment are included in the

sub-chapters of this chapter.

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

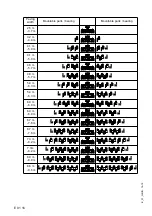

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......