F 5.1 11

F_5

.1_

01_G

B.

fm

11-

12

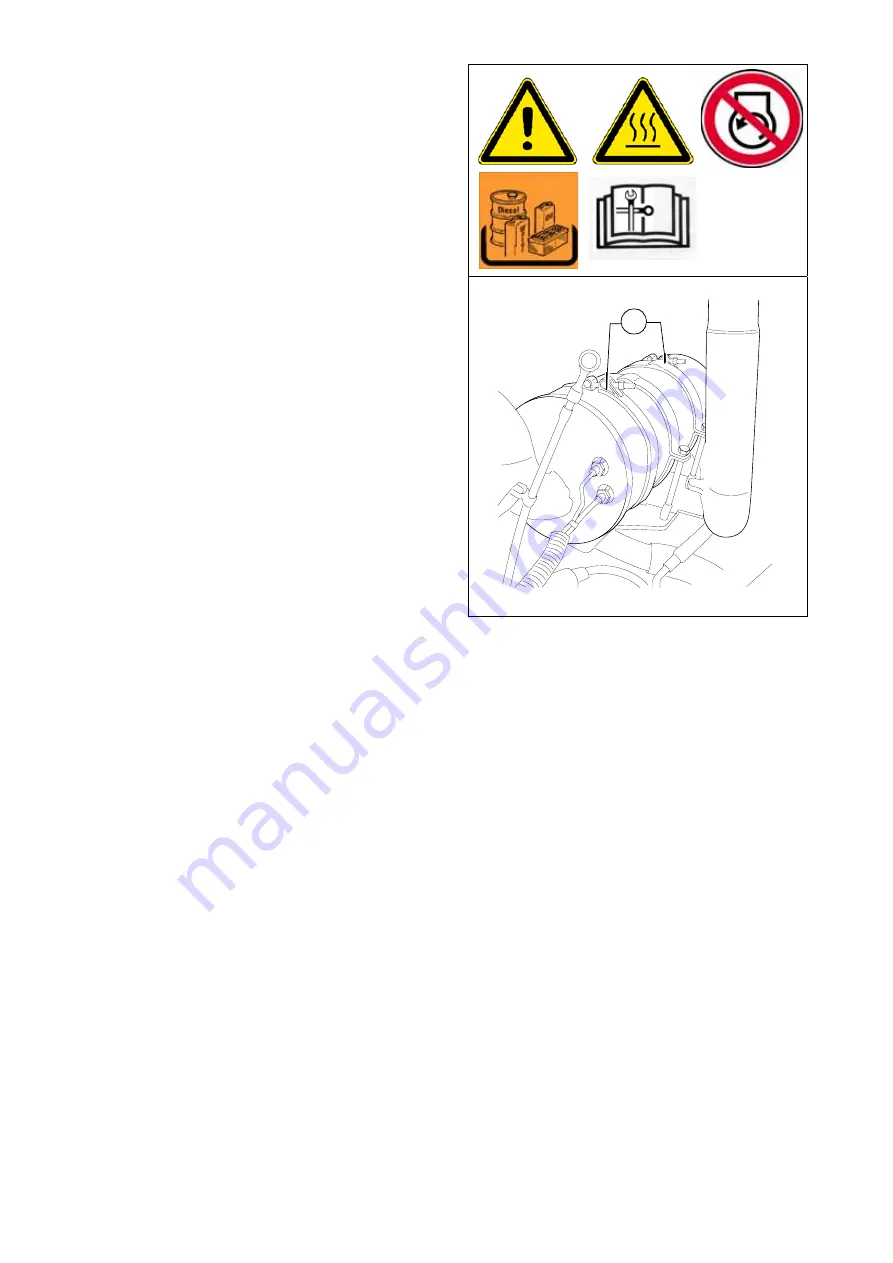

Engine exhaust system (7)

Cleaning of particle filter

m

As considerable amount of soot is accu-

mulated in the filter, the cleaning must

be performed under appropriate exhaust

system.

m

Clean the filter element removed with

oil-free and grease-free pressure air!

- Marking the flow of direction of the ex-

haust gas on the filter case.

- Remove the filter element by untight-

ening the two clips (a).

- First blow out the inlet side.

m

The pressure of the compressed air can

be max. 5 bars and the nozzle shall not

be closer to the filter edge than 10 cm.

- Carefully blow out all the filter passag-

es.

- Turn around the filter element, and re-

peat the process on the other side as

well.

- Repeat the process until no more carbon residue leaves the filter.

- Replace the filter element, taking care of the proper direction of flow.

A

After cleaning for a short while more soot discharge is expected during operation.

- In case of sticky, oily soot the filter must be heated to about 450°C and the cleaning

shall be carried out preferably with the hot filter.

m

The filter shall not be cleaned with water/steam or detergent in any case!

f

The carbon particles are harmful to your health! In case of filter change or cleaning,

wear appropriate protection gear!

Partikelfilter.eps

a

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......