F 7.2 3

F_7

.2_

01_G

B.

fm

3-

4

1.2

Points of maintenance

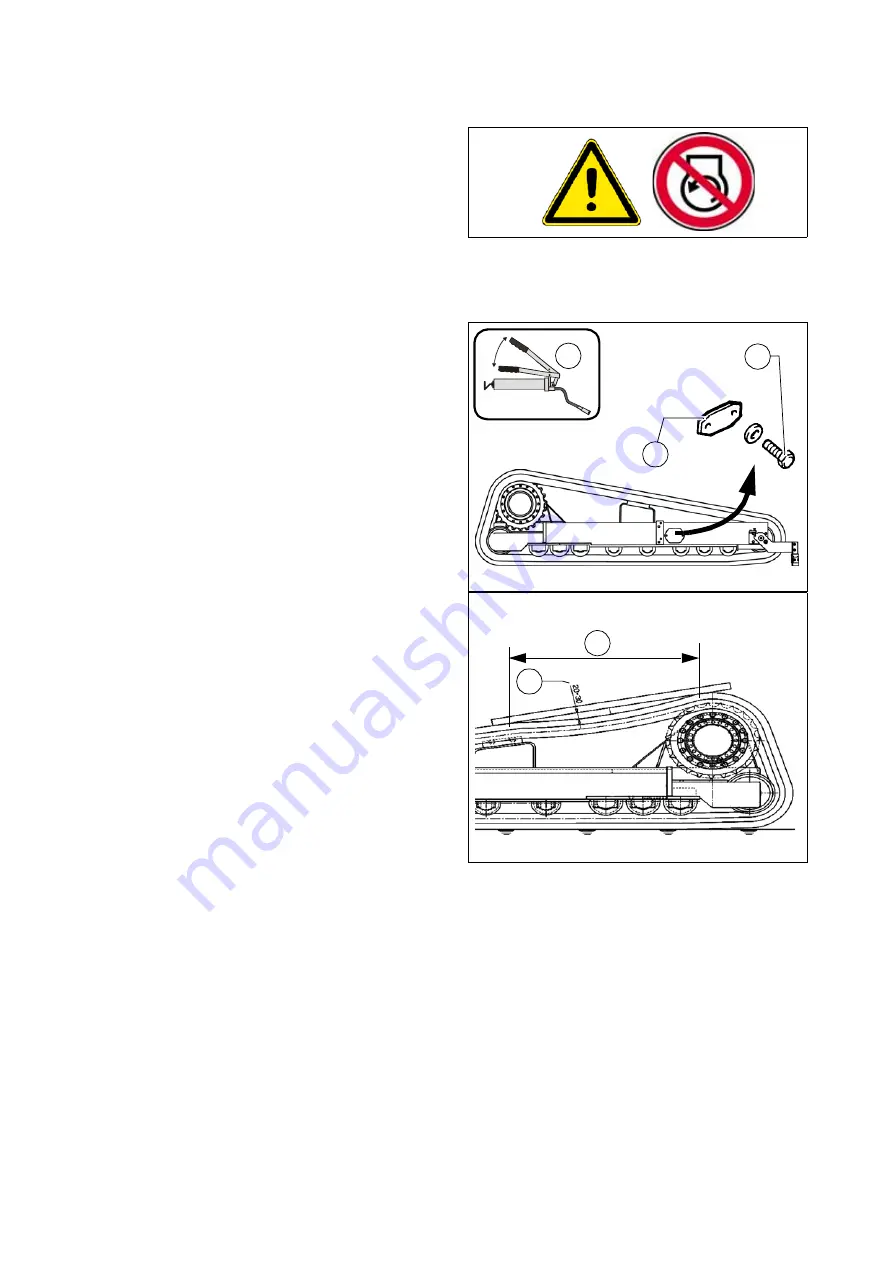

Track tightness (1)

m

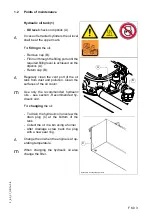

Slack tracks may slip out of the guides of

the rolls, drive and guide wheels and in-

tensive wear may take place.

m

Too tight tracks add to the wear of guide wheels and drive bearings, the pins and

bushes of the tracks as well.

Track tension: checking / adjusting:

- Track tightness can be adjusted with

grease press. The filling ports are lo-

cated on the LH and RH sides of the

running gear.

- Remove the screws (A).

- Remove cap (B).

- Screw the head module of the flat

grease nipple (toolbox) on the grease

press.

A

Over a length (L) of 1-1.5 m, slack (F) of

2-3 cm must be present. This applies in

linear fashion if the free length (L) is less

than or equal to 1-1.5 m (at least 4 track

links).

The extent of slack in the track is estab-

lished using a measuring rule. This in-

volves the dimension (F) being mea-

sured from the edge of the baseplate to

the measuring rule (at the centrepoint of

the slack in the track).

- Keep pressing grease into the track

tightening cylinder until the required

tightness is achieved.

A

On completion of the tensioning process, the grease gun is removed. Now the trac-

tion unit should be moved backwards and forwards approx. 1 complete turn of the

drive wheel. Check the position of tracks on idler wheel and drive wheel.

A

Repeat this procedure on both drive units!

- Remount the lid (B).

LW_DEM2.bmp

x

B

A

Spann_LWDEM.bmp

B

L

F

Summary of Contents for DYNAPAC Svedala Demag DF 115 C

Page 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Page 10: ......

Page 18: ......

Page 20: ......

Page 44: ......

Page 58: ......

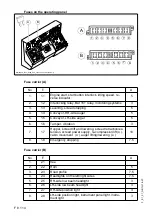

Page 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Page 96: ......

Page 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Page 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Page 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Page 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Page 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Page 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Page 134: ......

Page 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Page 152: ......

Page 154: ......

Page 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Page 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Page 168: ......

Page 180: ......

Page 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Page 220: ......

Page 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Page 226: ......