Step

Action

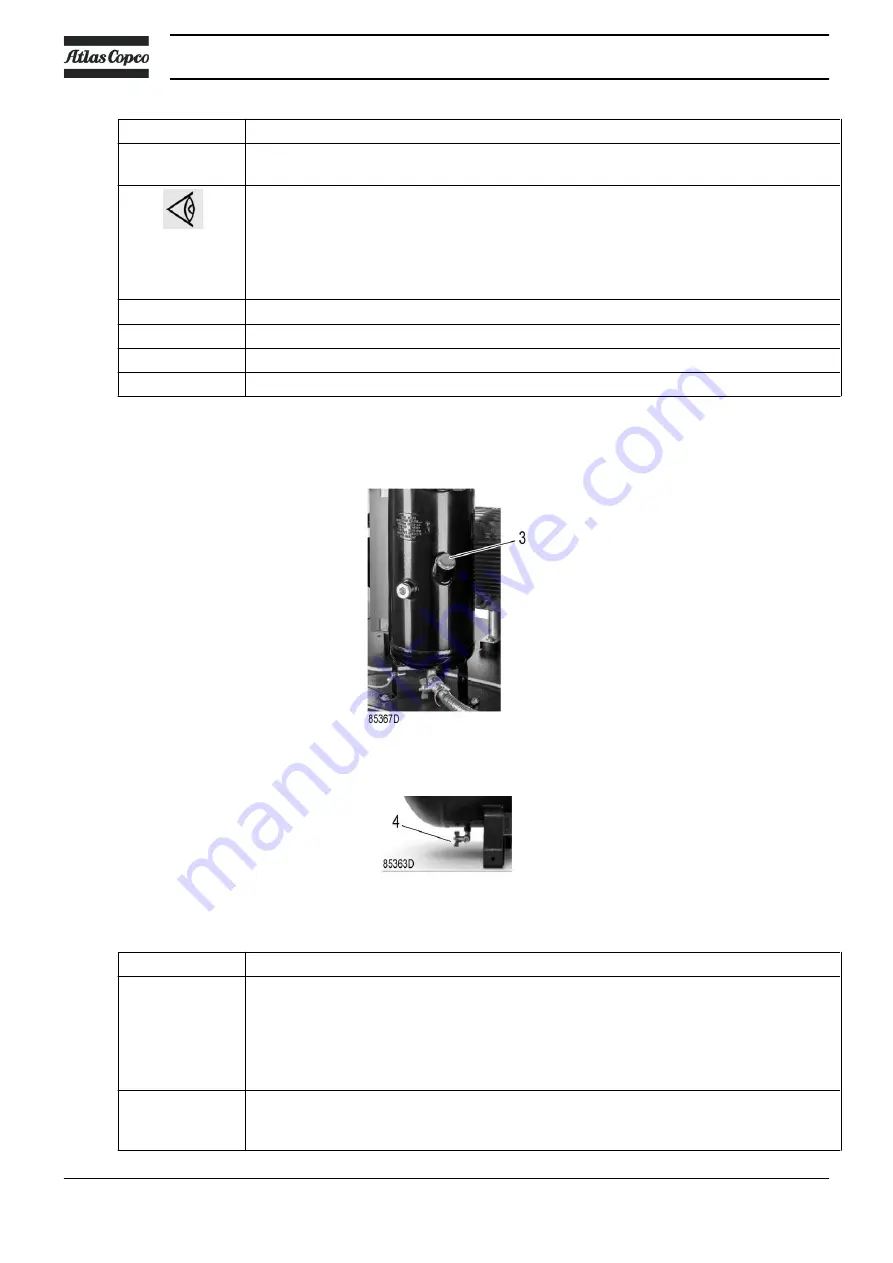

6

Check the oil level through the sight-glass (4). If the oil level is lower than the minimum

level, add oil until the maximum level is reached.

Never mix oils of different brands or types. A label, indicating the type of oil filled ex-

factory, is attached on the air receiver/oil tank.

Before carrying out any operation on the machine, ensure that the electric power supply

has been disconnected and that the machine has been depressurized.

Run the compressor for at least 5 minutes before checking the oil level. Do not wait too

long after the compressor is stopped and the foam is disappeared. The oil may migrate.

7

Refit and tighten filler plug (2).

8

Close drain valve (8) of the air receiver.

9

Run the compressor for a few minutes.

10

Close the front panel.

6.5

PDX/DDX filter change (option)

Oil filler plug

Drain valve, air receiver

Step

Action

1

Stop the compressor, close the air outlet valve, switch off the voltage and depressurise

by unscrewing oil filler plug (3) one turn to permit any pressure in the system to escape.

See section

.

On floor-mouned units, depressurise the filter by opening its drain valve.

If the compressor is fitted onto an air receiver, depressurise the air receiver by opening

condensate drain valve (4).

2

Unscrew the filter bowl. A whistling noise will warn you if the bowl is not fully

depressurised. If this occurs, the bowl should be screwed back and the venting should

be repeated.

Instruction book

64

2920 7119 21

Summary of Contents for G 15L

Page 1: ...INSTRUCTION BOOK OIL INJECTED ROTARY SCREW COMPRESSORS G 18 G 22 G 15L ...

Page 2: ......

Page 86: ......

Page 87: ......