90

Instruction book

9096 3313 00

Water requiremts for closed water circuits

The use of a closed water circuit minimises make-up water requirements. Therefore, the use of soft or even

demineralised water is economically feasible and eliminates the problem of scale deposits. Although the heat

exchanger is made of stainless steel, the water circuit connected to the compressor may require corrosion

inhibitors. Consult section

Cooling water requirements

to minimise problems due to bad water quality. If in any

doubt, consult Atlas Copco.

Add an anti-freeze product such as ethylene-glycol to the water in proportion to the expected temperature to

avoid freezing.

Water requirements for open water circuits

For open, non-recirculation water circuits, the major problems usually encountered are related to deposit

control, corrosion control and microbiological growth control. To minimize these problems, the water should meet

anumber of requirements. See section

Cooling water requirements.

If in any doubt, consult Atlas Copco.

5.3 Operation

General

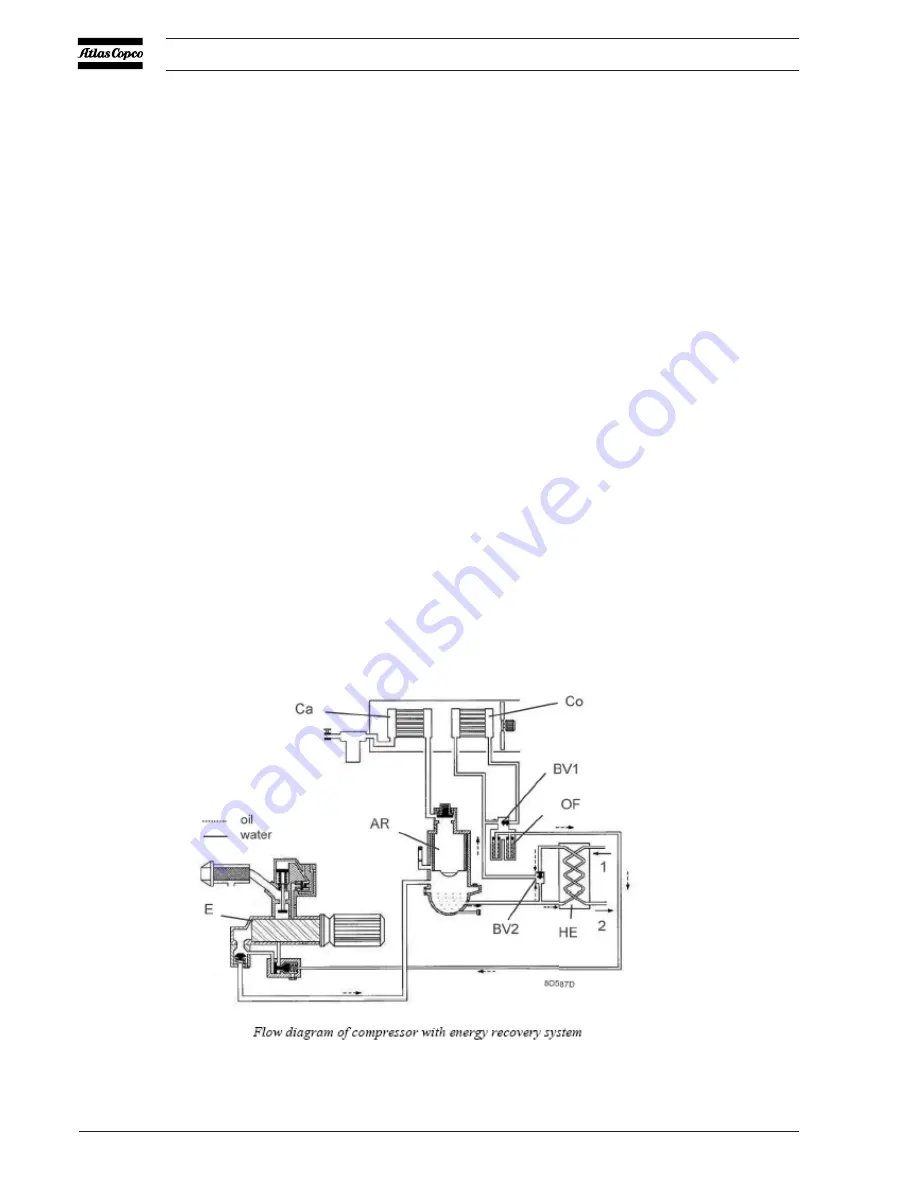

The compressor oil flow is controlled by two thermostatic valves (BV1 and BV2), ensuring reliable

compressor operation and optimum energy recovery.

Detailed description

Bypass valve (BV2) is integrated in the ER unit and controls the working of the oil/water heat exchanger (HE) of

the ER unit. Bypass valve (BV1) is integrated in the oil filter housing of the compressor and controls the working

of the main oil cooler (Co) of the compressor. Both bypass valves consist of an insert (thermostat) mounted in a

housing. Bypass valve BV2 has a separate housing, while BV1 is integrated in the oil filter housing.

Summary of Contents for GA 55+

Page 1: ...GA 55 GA 75 GA 90 Instruction book Atlas Copco Oil injected rotary screw compressors ...

Page 2: ......

Page 4: ......

Page 9: ......

Page 96: ...96 Instruction book 9096331300 6 Installation 6 1 Dimension drawings Centre of gravity ...

Page 98: ...98 Instruction book 9096331300 6 2 Installation proposal Compressor room example ...

Page 109: ...109 Instruction book 9096331300 ...

Page 123: ...123 Instruction book 9096331300 Procedure Oil system components Oil drain plugs ...

Page 145: ...145 Instruction book 9096331300 Notes ...

Page 146: ...146 Instruction book 9096331300 Notes ...

Page 147: ...147 Instruction book 9096331300 Notes ...

Page 148: ......

Page 149: ......