99

Instruction book

9096 3313 00

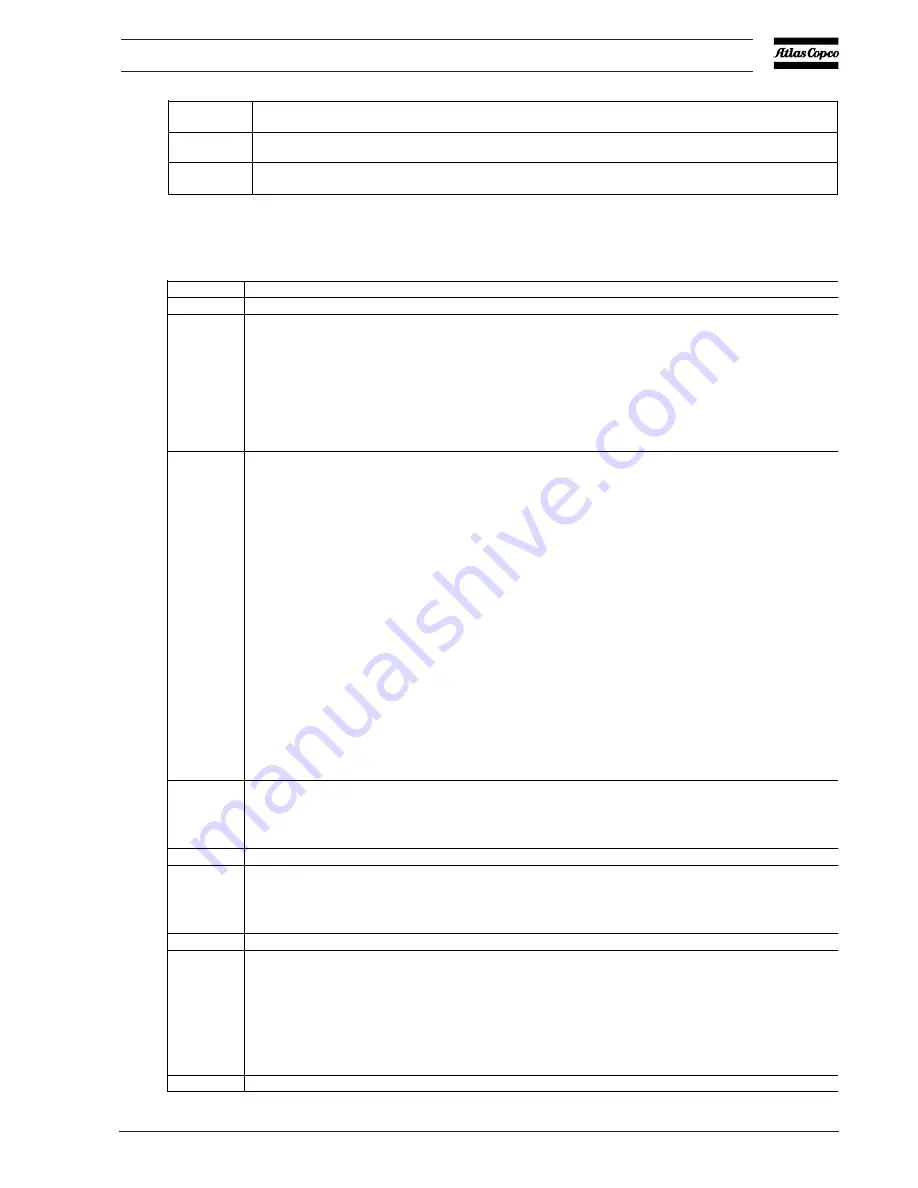

Description

(1)

Minimum free area to be reserved for the compressor installation

(2)

Ventilation proposals (on air-cooled compressors)

(3)

Cooling systems (on water-cooled compressors)

1

Install the compressor unit on a solid, level floor suitable for taking the weight.

2

Position of the compressed air outlet valve.

3

The maximum total pipe length (including interconnecting piping between compressor and

receiver) can be calculated as follows:

dp = (L x 450 x Qc

1. 85

) / (d

5

x p)

d = Inner diameter of the outlet pipe in mm

dp = Pressure drop (recommended maximum = 0.1 bar)

L = Length of outlet pipe in m

p = Absolute pressure at the compressor outlet in bar(a)

Qc = Free air delivery of the compressor in l/s

4

Ventilation: the inlet grids and ventilation fan should be installed in such a way that any

recirculation of cooling air to the compressor or dryer is avoided. The maximum air velocity

through the grids is 5m/s.

The maximum air temperature at the compressor intake is 46 °C (minimum 0 °C).

For air-

cooled compressors ventilation alternatives 1 and 3, the ventilation capacity required to

limit the compressor room temperature can be calculated as follows:

? Qv = 1.06 N/dT for GA Workplace compressors

? Qv = (1.06 N + 8)/dT for GA Workplace Full-Feature compressors

The cooling air of the dryer can be ducted outside

Qv= Required ventilation capacity in m

3

/s

N = Shaft input of compressor in kW

dT = Temperature increase in compressor room in °C

For ventilation alternatives 2 and 4:

the fan capacity should match the compressor fan

capacity at a pressure head equal to the pressure drop over the air ducts.

For water-cooled compressors, the ventilation capacity required to limit the

compressor room temperature can be calculated from:

? Qv = 0.13 N/dT for GA Workplace compressors

? Qv = (0.13 N + 8)/dT for GA Workplace Full-Feature compressors

Max. allowable pressure drop in ducting before or after the compressor = 30 Pa

5

The drain pipes to the drain collector must not dip into the water of the drain collector. Atlas

Copco has oil/water separators (type OSD or OSCi) to separate the major part of the oil from the

condensate to ensure that the condensate meets the requirements of the environmental

codes.

6

Control module with monitoring panel.

7

Power supply cable to be sized and installed by a qualified electrician.

To preserve the protection degree of the electric cubicle and to protect its components from

dust from the environment, it is mandatory to use a proper cable gland when connecting the

supply cable to the compressor.

8

Provision for energy recovery system.

9

Filter, type DD for general purposes. The filter traps solid particles down to 1 micron with a

max. oil carry-over of 0.5 mg/m

3

. A high-efficiency filter, type PD, maybe installed downstream

of a DD filter. This filter traps solid particles down to 0.01 micron with a max. oil carry-over of

0.01 mg/m

3

. If oil vapours and odours are undesirable, a QD type filter should be installed

downstream of the PD filter. It is recommended to install by-pass pipes over each filter together

with ball valves, in order to isolate the filters during service operations without disturbing the

compressed air delivery.

10

Safety valve

Summary of Contents for GA 55+

Page 1: ...GA 55 GA 75 GA 90 Instruction book Atlas Copco Oil injected rotary screw compressors ...

Page 2: ......

Page 4: ......

Page 9: ......

Page 96: ...96 Instruction book 9096331300 6 Installation 6 1 Dimension drawings Centre of gravity ...

Page 98: ...98 Instruction book 9096331300 6 2 Installation proposal Compressor room example ...

Page 109: ...109 Instruction book 9096331300 ...

Page 123: ...123 Instruction book 9096331300 Procedure Oil system components Oil drain plugs ...

Page 145: ...145 Instruction book 9096331300 Notes ...

Page 146: ...146 Instruction book 9096331300 Notes ...

Page 147: ...147 Instruction book 9096331300 Notes ...

Page 148: ......

Page 149: ......