For GA 37 VSD up to GA 90 VSD Full-Feature also press the test button on top of the electronic water drain

of the dryer until the air system between the air receiver and outlet valve is fully depressurised.

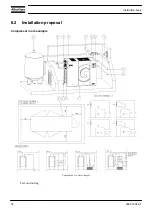

Press the emergency stop button (10).

Wait until the compressor has depressurized. Unscrew oil filler plug (FC) one turn to permit any pressure in

the system to escape. Remove the plug and add oil until the level reaches the filler opening. Fit and tighten

the plug (FC).

If the coloured part of service indicator (VI) shows full out, stop the compressor, switch off the voltage and

replace the air filter element. Reset the service indicator by pushing the knob in the extremity of the body.

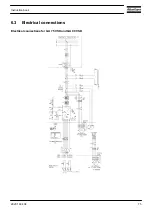

When automatic operation LED (8) is alight, the regulator is automatically controlling the compressor, i.e.

matching the compressor speed to the net pressure, starting and stopping the compressor whenever necessary.

Regularly check that condensate is discharged during operation. See section

and in case

of an OSD, also check the level in the oil collector; see section

The amount of condensate depends on environmental and working conditions.

7.6

Checking the display

Procedure

Control panel

Check the display (2) regularly for readings and messages. Normally, the display shows the compressor outlet

pressure, the motor speed and the abbreviations of the functions of the keys below the display.

Always check the display (2) and remedy the trouble if alarm LED (7) is alight or blinks. See section Status

data menu.

The display (2) will show a service message if a service plan interval has been exceeded or if a service level

for a monitored component has been exceeded. Carry out the service actions of the indicated plans or replace

the component and reset the relevant timer; see section Status data menu.

Regularly press the arrow down key (3) on the main screen to call up information about the actual compressor

condition. See section

Quick look at actual compressor status.

Instruction book

86

2920 1634 04