8

Problem solving

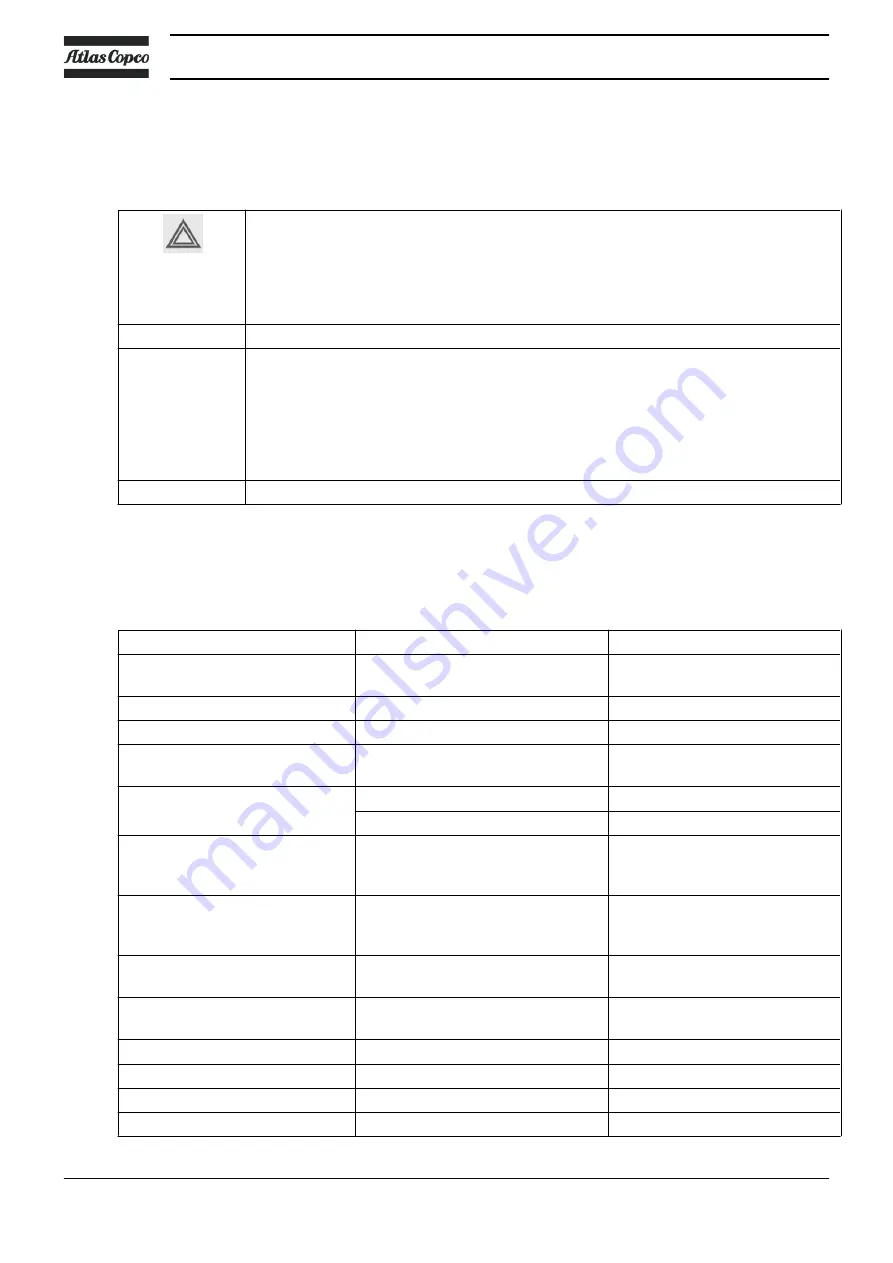

Warning

Before carrying out any maintenance, repair work or adjustment, press the stop button,

wait until the compressor has stopped, press the emergency stop button and switch off

the voltage. Close the air outlet valve, open the manual drain valve. Depressurise the

compressor by opening the oil filler plug (FC) one turn.

For location of components, see sections

,

and

.

Open and lock the isolating switch.

The air outlet valve can be locked during maintenance or repair as follows:

• Close the valve.

• Remove the screw fixing the handle with the wrench delivered with the

compressor.

• Lift the handle and turn it until the slot of the handle fits over the blocking edge on

the valve body.

• Fit the screw.

Always apply all relevant

Faults and remedies, compressor

On compressors equipped with an Elektronikon I regulator, if the alarm LED is lit or flashes,

consult section

Condition

Fault

Remedy

Compressor starts running, but

does not load after a delay time

Solenoid valve out of order

Replace valve

Inlet valve stuck in closed position

Have valve checked

Leak in control air tubes

Replace leaking tubes

Minimum pressure valve leaking

(when net is depressurized)

Have valve checked

Compressor does not unload,

safety valve blows

Solenoid valve out of order

Replace valve

Inlet valve does not close

Have valve checked

Condensate is not discharged

from condensate separator during

loading

Discharge tube clogged

Check and correct as necessary

Float valve malfunctioning

(condensate drain, units without

dryer)

Remove float valve assembly,

clean and check

On Full-Feature units: electronic

drain malfunctioning

Press test button, replace if

necessary

Compressor air output or pressure

below normal

Air consumption exceeds air

delivery of compressor

Check equipment connected

Choked air filter element

Replace filter element

Solenoid valve malfunctioning

Replace valve

Leak in control air tubes

Replace leaking tubes

Inlet valve does not fully open

Have valve checked

Instruction book

80

API451763