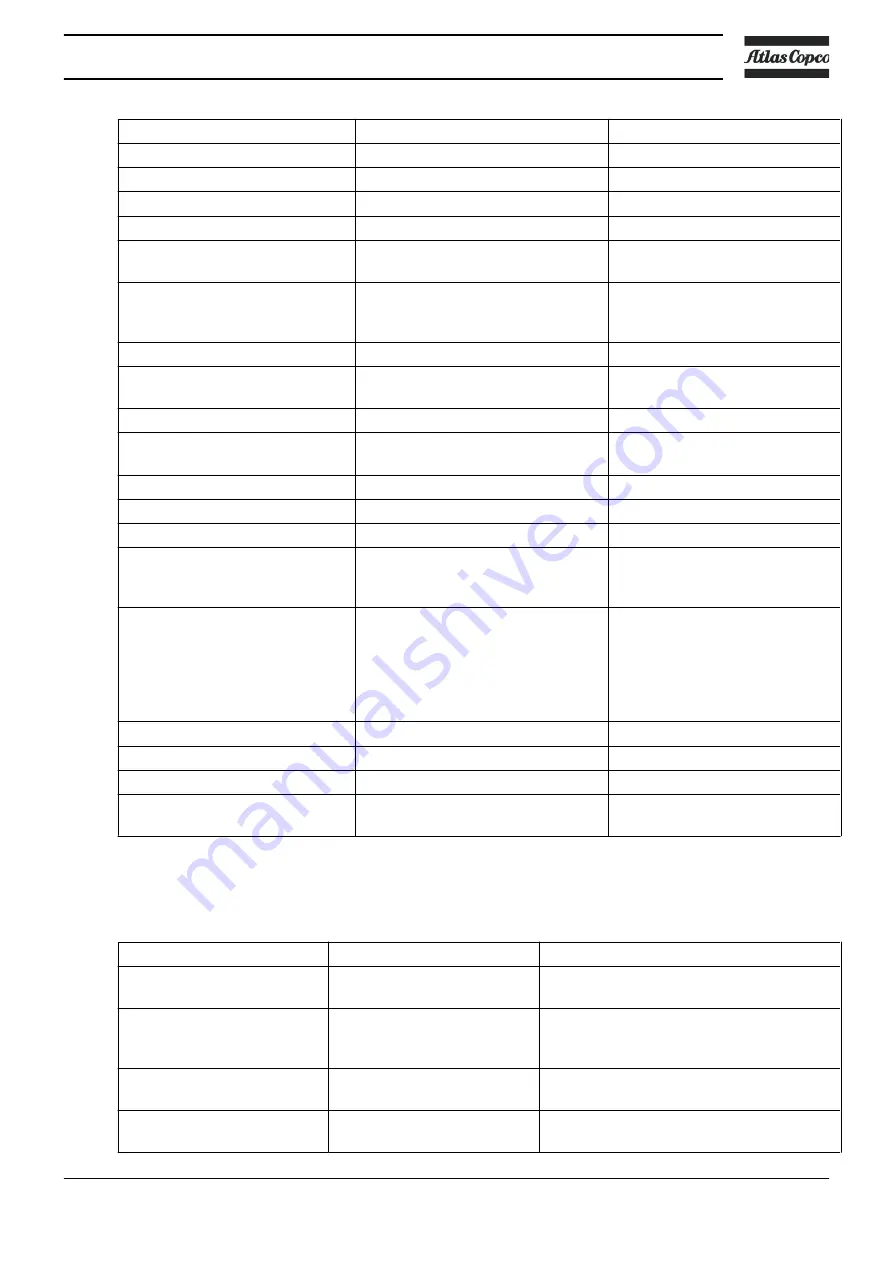

Condition

Fault

Remedy

Oil separator clogged

Replace oil separator element

Air leakage

Have leaks repaired

Safety valve leaking

Have valve replaced

Compressor element out of order

Consult Atlas Copco

Excessive oil consumption; oil

carry-over through discharge line

Incorrect oil causing foam

Change to correct oil

Oil level too high

Check for overfilling. Release

pressure and drain oil to correct

level.

Oil separator defective

Replace oil separator element

Malfunctioning of the scavenge line

Replace non-return valve in the

scavenge line

Safety valve blows after loading

Inlet valve malfunctioning

Have valve checked

Minimum pressure valve

malfunctioning

Have valve checked

Safety valve out of order

Have valve replaced

Compressor element out of order

Consult Atlas Copco

Oil separator element clogged

Replace oil separator element

Compressor element outlet

temperature or delivery air

temperature above normal

Oil level too low

Check and correct

On air-cooled compressors,

insufficient cooling air or cooling air

temperature too high

Check for cooling air restriction or

improve ventilation of the

compressor room. Avoid

recirculation of cooling air. If

installed, check capacity of

compressor room fan

Oil cooler clogged

Clean cooler

Bypass valve malfunctioning

Have valve tested

Air cooler clogged

Clean cooler

Compressor element out of order

Consult Atlas Copco Customer

Centre

Faults and remedies, dryer

For all references hereafter, consult section

.

Condition

Fault

Remedy

Pressure dew point too high

Air inlet temperature too high

Check and correct; if necessary, clean the

aftercooler of the compressor

Ambient temperature too high Check and correct; if necessary, draw

cooling air via a duct from a cooler place or

relocate the compressor

Shortage of refrigerant

Have circuit checked for leaks and

recharged

Refrigerant compressor does

not run

See below

Instruction book

API451763

81